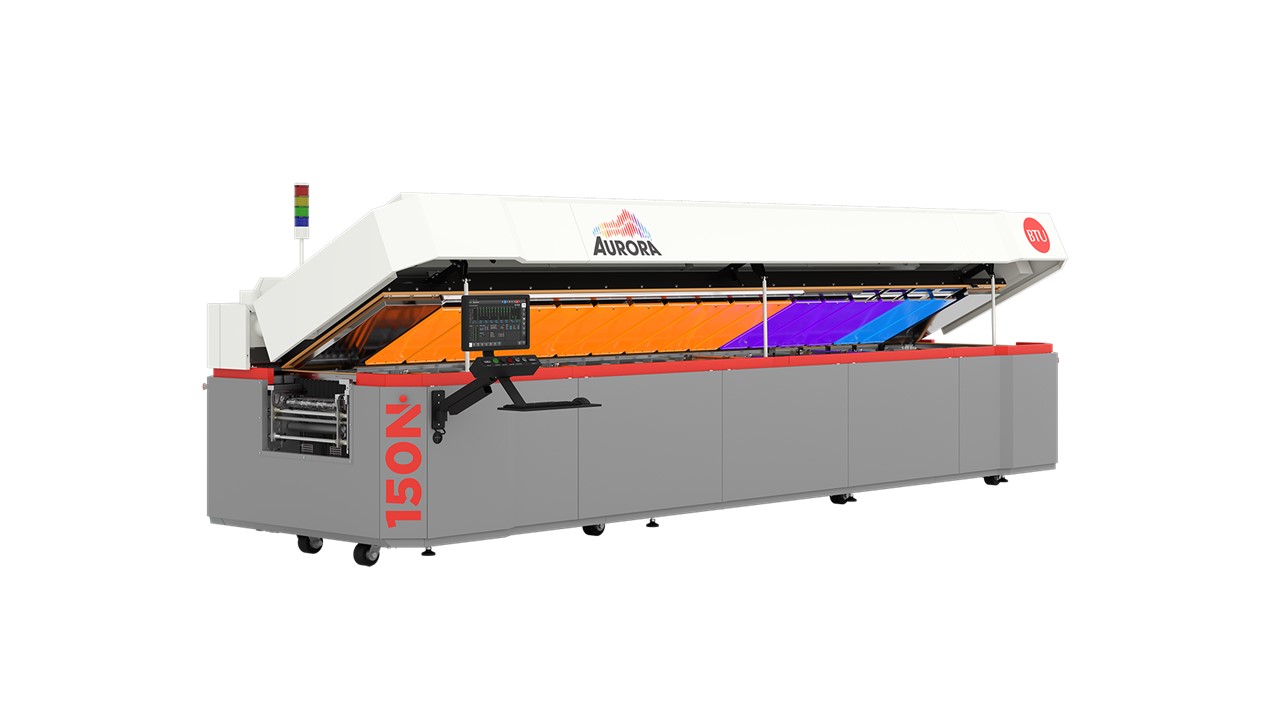

BTU International, Inc., a leading supplier of advanced thermal processing equipment for the electronics manufacturing market, will exhibit in Hall 4A, Stand 210 in conjunction with its representative, Stratus Vision. The show is scheduled to take place May 9-11, 2023, in Nuremberg, Germany. The event will mark the debut of the Aurora platform – the newest development in a long line of reflow ovens from BTU.

Aurora is guiding the way to the lights out Industry 4.0 factory of the future by seeing reflow in a new light. Using the combination of newly integrated process control technologies and innovative WinCon 8 reflow oven control software, Aurora provides the ultimate in thermal process performance.

“We are thrilled to bring the all-new Aurora to the market at SMTconnect in Nuremburg,” said Rob DiMatteo, general manager of BTU International. “The Aurora platform has been fully modernized from the user interface to the advanced options on the conveyor system – it is the reflow oven for the future,” added DiMatteo.

Aurora systems feature modern conveyor options, fully updated user interface, integrated Aqua Scrub™ flux management technology, innovative Smart Power energy savings software, and advanced process control technologies. The Aurora’s conveyor system offers five moveable rails with advanced center support options as well as dual-lane, dual-speed configurations. The conveyor platform, which can accommodate even wider boards than previous models, was designed concurrently to allow for the use of common parts.

The new Wincon 8 reflow oven control system was designed to mimic the style of SEMI E95 compliant interfaces and features a simplified and configurable main monitor graphic. The GUI navigation for Wincon 8 uses icons instead of menus, which significantly enhances the language independence of the control system.

To further minimize Cost of Ownership, the extraction of flux laden gasses has been fully optimized and made integral to the oven heated zones, allowing even more efficient operation of the Aqua Scrub system, resulting in less maintenance and downtime. The Smart Power feature has been upgraded for Aurora to use the available facility’s power even more efficiently during oven start-up allowing customers to facilitate a smaller electrical service to the oven. Aurora’s combination of superior thermal performance, process flexibility and vision for the future sets the new standard for reflow ovens today – and into the future.

To learn more visit www.btu.com.

About BTU International

BTU International, a wholly-owned subsidiary of Amtech Group (Nasdaq: ASYS), is a global supplier and technology leader of advanced thermal processing equipment in the electronics manufacturing market. BTU’s high-performance reflow ovens are used in the production of SMT printed circuit board assemblies and in semiconductor packaging processes. BTU also specializes in precision controlled, high-temperature belt furnaces for a wide range of custom applications, such as brazing, direct bond copper (DBC), diffusion, sintering and advanced solar cell processing. BTU has operations in North Billerica, Massachusetts, and Shanghai, China, with direct sales and service in the U.S.A., Asia and Europe. Information about BTU International is available at www.btu.com.