The rework of electronic assemblies is becoming more and more important in the global electronics industry. There are several reasons for this – such as components shortage caused among other things by supply chain problems, or the increasing importance of sustainability in order to maintain added value for as long as possible and in a way that conserves resources. Likewise, the ever more powerful rework systems are increasingly being used for prototype production and small series – primarily also due to reproducible processes. Trends such as 5G and electromobility are also important market drivers that are continuously contributing to the increasing use of rework systems.

Ersa is the leading system manufacturer for electronics production and, with its hybrid rework systems, offers the fitting solution for all applications in rework or component repair.

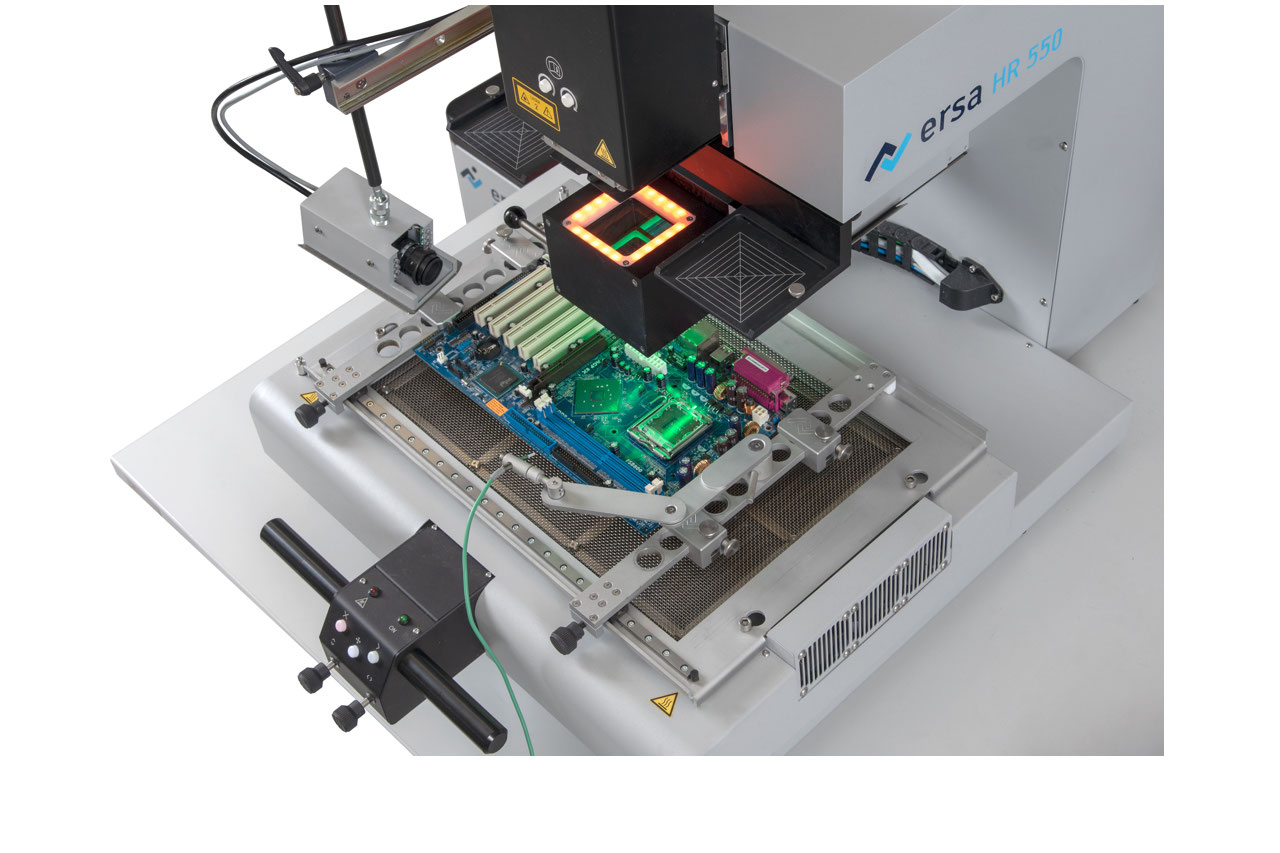

The portfolio starts with the hand-held station HR 100 and HR 200, an “out of the box” table-top unit. It then goes on to semi-automated systems such as the HR 550 and fully automated high-end systems like the flagship Ersa HR 300/3P for automatic repair of SMT components such as BGA and MLF. With its range of hybrid rework systems, Ersa covers all different electronic components “from micro to mega” (01005 chips to BGAs with 100 x 100 mm side length) and can process everything from the smallest electronic assemblies to big boards (625 x 1,250 mm). Thanks to aperture technology, no component-specific nozzles or inserts are required. The convenient HRSoft 2 operating software supports the user in achieving and documenting perfect desoldering and soldering profiles in a process-reliable and reproducible manner.

Experience Ersa Rework Systems live at SMTconnect in Nuremberg from May 9 to 11 – Ersa experts will be happy to answer your questions and share their in-depth process know-how. Also on display in the Franconian metropolis: the world´s first IoT soldering station i-CON TRACE as well as the product launch of the new i-CON Mark 2 soldering station series, which sets new trends in soldering performance.

We are looking forward to your visit at Ersa booth 115 in hall 4!