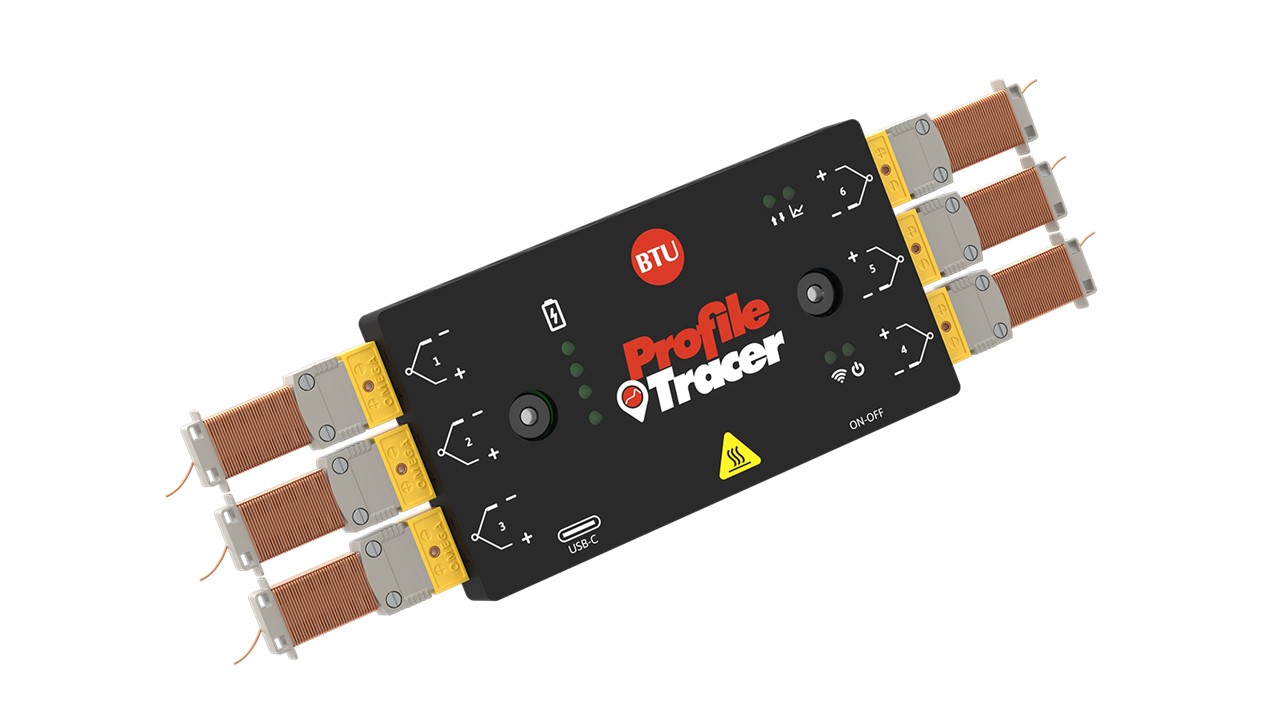

BTU International, Inc., a leading supplier of advanced thermal processing equipment for the electronics manufacturing market, will exhibit in Hall 4A, Stand 210 at SMTconnect, scheduled to take place May 9-11, 2023 in Nuremberg, Germany. At the show, BTU will show its brand new Profile Tracer, a next-generation thermal profiling tool providing real-time data acquisition for oven optimization by identifying inconsistencies due to temperature variables at both the product level and at the heat source.

This exclusive tool by BTU measures dual temperature locations as well as vibration at real-time product temperature while the product completes its thermal path. Profile Tracer’s predictive capabilities go beyond traditional profilers by using internal sensors and top-of-the-line heat resistant optic windows to measure the thermal profile at the same time, location on the path, and conditions at the product level as well as at the heat source.

Profile Tracer supports Industry 4.0 capabilities by acquiring data sets, enabling data communication, and increasing database analysis using In-One-Pass (I-O-P) technology. Profile Tracer software is part of the Wincon™ ecosystem of powerful diagnostic and analytical tools supporting overall process optimization.

Profile Tracer detects multiple variables affecting the thermal profile in one pass. Additionally, it reduces initial oven setup time and facilitates process optimization. The unit’s compact design, user-friendly software, modest cost, and integration into the BTU system, contribute to overall reduction in the total Cost of Ownership.

To learn more visit www.btu.com.

About BTU International

BTU International, a wholly-owned subsidiary of Amtech Group (Nasdaq: ASYS), is a global supplier and technology leader of advanced thermal processing equipment in the electronics manufacturing market. BTU’s high-performance reflow ovens are used in the production of SMT printed circuit board assemblies and in semiconductor packaging processes. BTU also specializes in precision controlled, high-temperature belt furnaces for a wide range of custom applications, such as brazing, direct bond copper (DBC), diffusion, sintering and advanced solar cell processing. BTU has operations in North Billerica, Massachusetts, and Shanghai, China, with direct sales and service in the U.S.A., Asia and Europe. Information about BTU International is available at www.btu.com