CyberOptics® Corporation (NASDAQ: CYBE), a leading global developer and manufacturer of high-precision 3D sensing technology solutions will debut the Dual-Mode Multi-Reflection Suppression® (MRS®) sensor-enabled SE3000™ SPI system in Hall 4A, Stand 210 at SMTconnect, scheduled to take place May 10-12, 2022 in Nuremberg, Germany. The company also will demonstrate the SQ3000™ Multi-Function system for AOI, SPI and CMM and feature the new SQ3000™+ system.

The new Dual-Mode MRS sensor for the SE3000™ SPI system provides maximum flexibility for dedicated solder paste inspection applications, with one mode for high-speed and another mode for high resolution inspection. The high accuracy, repeatability and reproducibility of the SE3000 make it ideal for effectively detecting insufficient or excess paste, height, area and other SPI applications.

MRS technology inhibits reflection-based measurement distortions caused by shiny components and surfaces for highly accurate inspection. CyberOptics’ unique sensor architecture simultaneously captures and transmits multiple images in parallel. Proprietary 3D fusing algorithms merge the images together, delivering metrology grade accuracy at production speed.

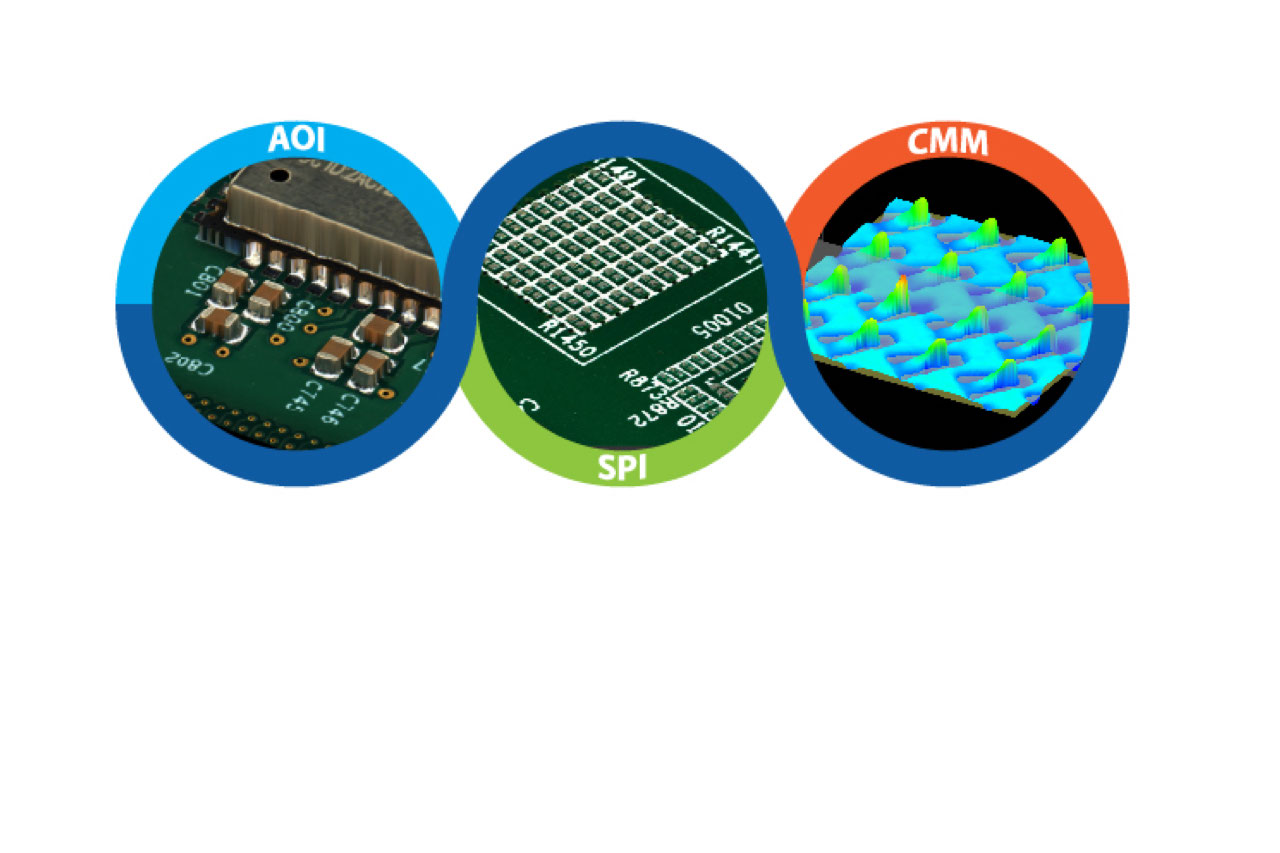

Customers worldwide are improving their yields and processes with CyberOptics’ MRS-Enabled systems. The SQ3000+ Multi-Function system for inspection and metrology is an extension of the multi-award-winning SQ3000 platform deemed best-in-class, that not only conducts AOI and SPI, but uniquely delivers in-line, full coordinate measurement (CMM) data in seconds, not hours.

The SQ3000+ all-in-one system offers a combination of unparalleled high accuracy and high speed, with an even higher resolution sensor. The system is specifically designed for high-end applications including advanced packaging, mini-LED, advanced SMT, 008004/0201 SPI, socket metrology and other challenging CMM applications.

For more information, visit cyberoptics.com