Kerafol and X2F are teaming up to develop state-of-the-art thermal management solutions for electronic devices by leveraging the advantages of Kerafol’s thermally conductive materials and X2F’s patented controlled-viscosity molding technologies. The partnership aims to provide advanced thermal management solutions that meet the ever-increasing high-performance demands of the electronics industry.

Combining Kerafol’s high-performance thermoplastic elastomeric materials with X2F’s controlled-viscosity molding (CVM) technology delivers a higher-performance alternative to conformal coating, potting, and sealing of electronics, achieving superior environmental protection and heat dissipation while reducing processing times and manufacturing costs.

All electronics are susceptible to damage caused by environmental contamination, vibration, shock, electrostatic discharge (ESD) and thermal stresses. That’s why protective strategies are critical to ensuring long-term reliability. Traditionally, multiple methods have been used to address each mode of failure. For example, spraying a conformal coating onto a PCB protects electronics from dust, moisture, and other environmental contaminants, while filling the assembly with a potting compound enhances its mechanical strength and adds electrical insulation. As devices become smaller, faster, and more functional, thermal management solutions, such as thermally conductive pads, fillers, adhesives, etc., have become even more important for dissipating and distributing excess heat, preventing damage caused by overheating and thermal cycling. Addressed separately, each of these protective strategies adds time, complexity, and cost to a manufacturing process.

X2F and Kerafol have joined forces, creating a strategic partnership to deliver advanced protection for electronic devices. This collaboration ensures long-term reliability by safeguarding against contamination, vibration, shock, ESD, and thermal stresses, all in a streamlined, one-step process.

This comprehensive single-step environmental protection solution reduces complexity throughout the supply chain. It simplifies manufacturing, warehousing logistics, and production processes while enhancing long-term reliability. The partnership has introduced cutting-edge technology to the market, integrating high-performance thermal materials with CVM technology, providing manufacturers with cost-effective solutions that ensure high reliability in electronic systems.

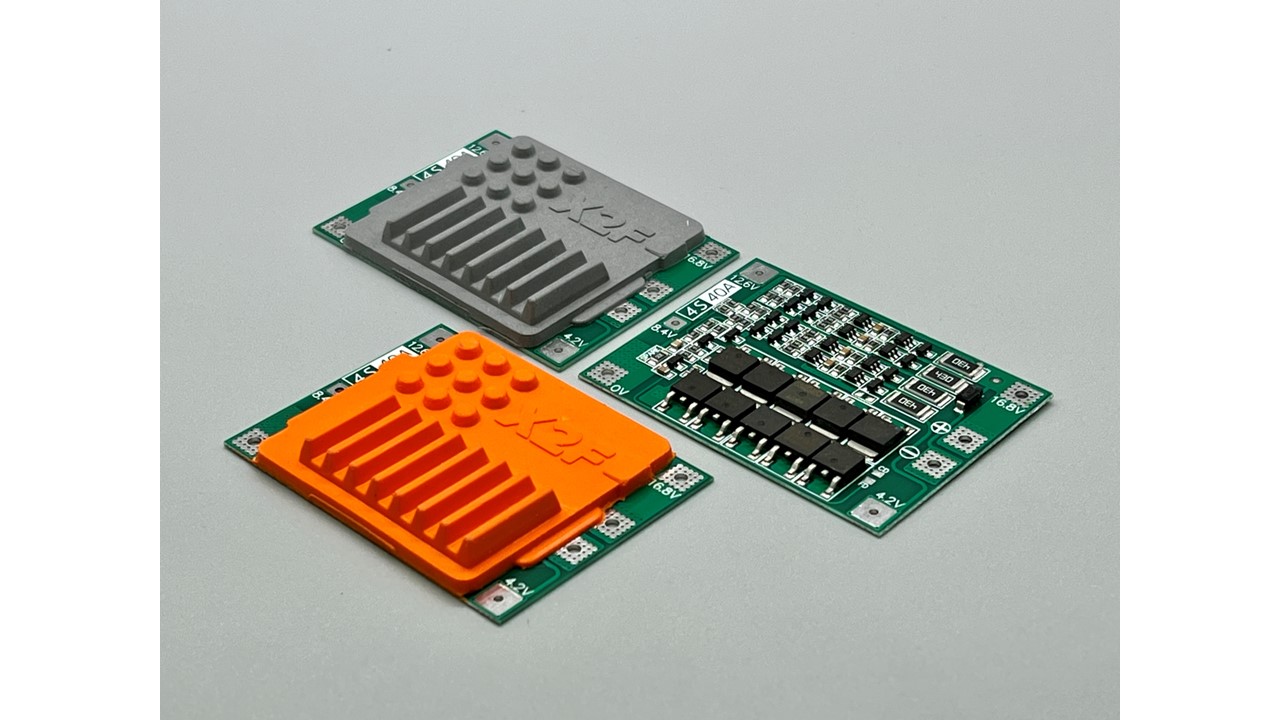

Kerafol’s new silicone-free KERAMOLD® materials are soft and flexible, highly electrically isolating, thermally conductive and can be molded into complex geometric shapes, making them ideal for overmolding electronics. Additionally, KERAMOLD® materials are easy to handle, process at room temperature and require no refrigeration, drying, pre-treatment or post cure.

The X2F CVM approach to overmolding electronics combines patented hardware, sensors, and software to control the viscosity of ultra-high-performance materials and optimize mold pressure. Heat is generated electrically for continuous temperature control, and a multi-step “pulse-pack” extrusion process is used to fill the mold. By continuously sensing mold cavity pressure and deploying its “pack-hold-and-repack” process, X2F builds to the best mold pressure for the application. As a result, X2F can mold ultra-high-performance materials and complex geometries that were previously considered unmoldable.

“Our KERAMOLD® thermoplastic elastomers flow extremely well on X2F’s CVM equipment, wrapping the complex contours of components and PCBs. And because of its softness, when pressure is applied it conforms to surfaces unlike any other material in the industry, without damaging sensitive components,” says Wolfgang Hoefer, Thermal Products Division Manager at Kerafol.

“We are excited about this collaboration because it provides our customers a new approach for heat management in electronics that is far superior to conformal coating and potting in many applications.” says Mike Slowik, CEO of X2F.

The need for higher performance electronics is growing, especially in high-power distribution systems and electric vehicle (EV) batteries. The synergy between X2F’s patented CVM molding technologies and Kerafol’s advanced KERAMOLD® materials offers distinct advantages. This powerful combination not only shields against contamination, vibration, shock, ESD but also significantly enhances thermal performance. The results provide long-term reliability for next-generation electronics while streamlining manufacturing complexity, reducing processing times and cutting costs.

About X2F

X2F, based in Loveland, Colorado, addresses pain points in the electronics industry with their patented CVM molding technology that controls material viscosity with a pulse-packing approach, enabling the use of materials previously thought to be impossible to mold. Their equipment creates opportunities for a variety of industries to realize high-value benefits from ultra-high-performance materials while achieving complex over-molded part geometries that are lighter, stronger, more affordable, and sustainable. For more information, visit www.x2f.com.

About Kerafol

Kerafol, located in Bavaria, Germany, are experts in formulating high-performance materials that utilize ceramics. Their materials are used in a wide variety of innovative applications such as electronics, filtration, sensors and fuel cells. Kerafol is globally known, especially for the product series KERATHERM® with a wide range of thermal interface materials, including tapes, gap pads and gap fillers. Their new KERAMOLD® injection molding granulate materials provide both electrical insulation and thermal conductivity and can be molded into complex 3D geometric shapes. For more information, visit www.kerafol.com.