Intraratio, a provider of enterprise software solutions, is pleased to offer a comprehensive approach to managing and optimizing manufacturing operations. With the integration of the company’s RunCard (MES) and DataCard (Yield/IoT Management System), Intraratio is able to provide manufacturers with a complete solution that can automate quality control and traceability, helping them to achieve greater efficiency, reduce waste, and improve overall product quality and profit margins.

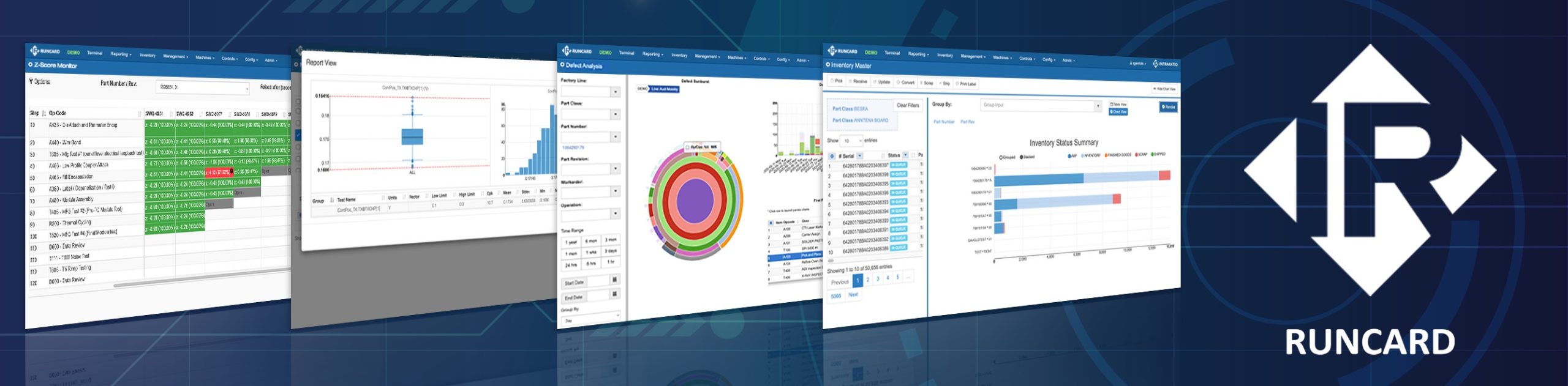

The RunCard system allows manufacturers to track and manage production in real-time, providing insights into production performance, scheduling, inventory tracking and quality control. The DataCard system complements this by providing detailed analysis of production data, including machine parameters, sensor data, tester data, including optical and x-ray inspection data, providing the unparalleled ability for manufacturers to identify and address both inefficiencies and defects.

The innovative use of IoT technology in the DataCard system also enables manufacturers to gain real-time insights into machine and product testing performance, allowing them to quickly respond to changes in demand or production issues. Inraratio’s RunCard and DataCard integrated solutions represent a new level of innovation and data decision automation for manufacturing process optimization, providing manufacturers with powerful tools for improving efficiency, quality, and profitability, from NPI to high volume multi-factory operations.

For more information about Intraratio, visit intraratio.com

About Intraratio

Backed by over 30 years of global high tech engineering and manufacturing experience, the Intraratio platform breaks the accessibility and integration limitations of existing software systems – putting data-driven innovation and improvements at the fingertips of those who are passionate about operational excellence.