At this year’s Control, the many advantages of Viscom AG’s X-ray inspection technologies are combined into a central theme. Visitors to booth 9314 in hall 9 of this international trade fair in Germany will learn more about the versatile uses of microfocus X-ray tubes as well as quality assurance for battery cells and final assembled products.

The right technology and related equipment are needed if demanding testing and digitalization functions are to be reliable, efficient and non-destructive. In this regard, X-rays are the perfect choice for comprehensive quality assurance in many manufacturing processes. At the same time as showcasing its high-end optical inspection systems as well as ultra-modern X-ray solutions for electronic assemblies at SMTconnect and PCIM in Nuremberg, Viscom is also featuring its X-ray technologies for a wide spectrum of further areas of application at Control 2023 from May 9 to 12 in Stuttgart.

One innovative component about which detailed information can be obtained is, for example, the XT9320 D open microfocus X-ray tube from Viscom. With its high acceleration voltage of up to 320 kV, it can easily penetrate mechanical parts made of particularly dense materials. Its large target power of up to 640 W makes rapid inspection possible even if complex CT with very many single exposures is needed. The tube is ideally suited for use in computer tomography systems designed for the quality control of industrial products. Flexible use with smaller outputs for delicate inspection objects is also possible. Viscom offers both direct beam as well as transmission and rod anode tubes for different tasks.

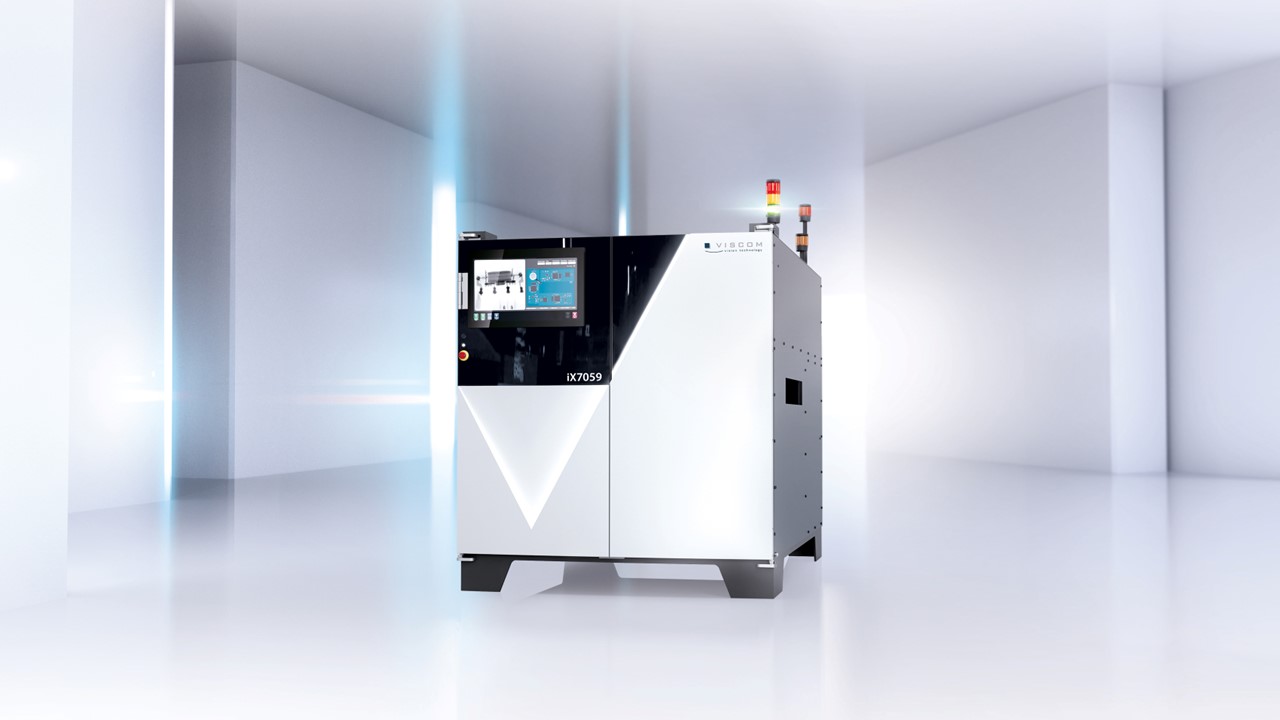

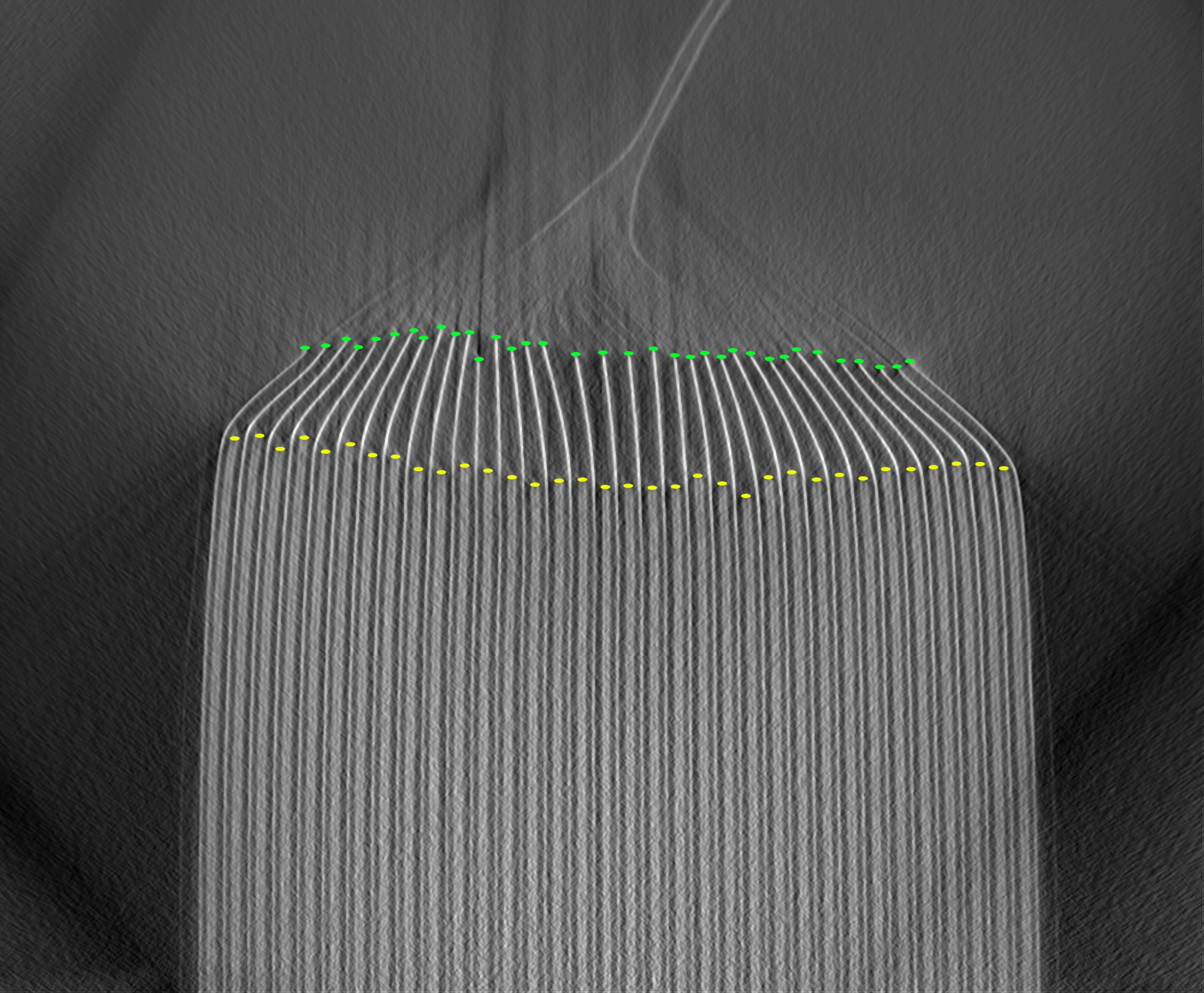

Specialists from Exacom GmbH are presenting details of the special features of automated X-ray inspection of battery cells at the Control trade fair. The subsidiary of Viscom has developed many innovative solutions for this increasingly important product range. At the Viscom booth, the special requirements for an X-ray inspection after final assembly will also be addressed in detail. In this context, the company’s iX7059 inspection systems can be integrated into production lines or alternatively used as an island concept. Foreign objects that may lead to short circuits or missing components that later affect proper functionality are reliably detected. High-performance handling enables a high throughput – with workpiece carriers and precise fit.