Recently, the German DIE bonding specialist Tresky GmbH introduced the reliable pre-sintering process with copper pastes. Now Tresky is expanding this process area with the precise application and pre-sintering of thixotropic silver pastes from all leading manufacturers.

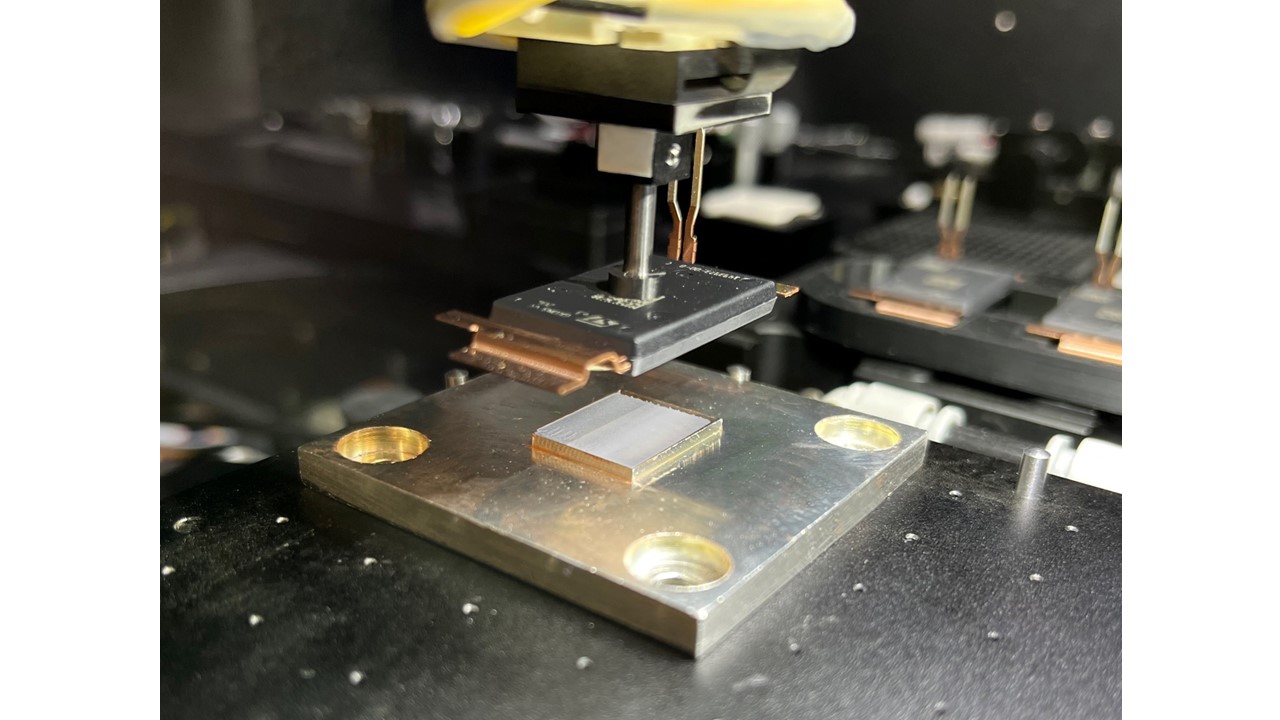

“The precise application of a silver sintering paste is the first step for a reliable, reproducible pre-sintering process in packaging technology. We use our SQ-Nozzle, which enables sequential, very precise, and large-area application of paste deposits with high thixotropic material properties.,” explains Daniel Schultze, Managing Director of Tresky GmbH. The silver paste is applied in one process step, whereby defined layer heights and thicknesses can be applied, which are controlled by means of layer thickness measurement. With the help of a triangulation laser, the layer thickness of the applied sinter paste is measured without contact. This guarantees that the dispensing of the predefined amount of paste is carried out exactly and therefore reproducible sintering results are achieved.

“During our test trials, we processed silver pastes for the wet sintering process from all leading manufacturers and achieved very good results, without exception. The thixotropic paste structure was of course a challenge, but we managed to get to grips with it,” Schultze looks back. In the sintering process, the chip is bonded to the substrate by silver or copper paste, not only electrically but also thermally. This is done with the help of heat and pressure. In this process, the silver particles are bonded together by diffusion processes. “The advantage over normal soldering processes is the very high thermomechanical stability, which is necessary for power electronics,” Schultze explains.

After applying the silver paste, the power semiconductor is placed inside the machine in a second process step. “The combination of paste application and component placement, coupled with the already established Tresky process modules, enables a cycle-time-optimised production in which reproducible results are guaranteed. Furthermore, the sintering process can be combined with additional options, such as the processing of wafers, the pressing of components with high pressure and the dispensing of a tacking agent,” says Schultze.

Tresky GmbH will present the pre-sintering processes with silver and copper pastes as well as all other DIE bonding applications at two trade fairs in spring and early summer this year. From 9 to 11 May, Tresky will be exhibiting at PCIM Europe in Nuremberg in Hall 6, booth 434. This will be followed by participation at the ECTC in Orlando, Florida, from 30 May to 2 June.

About Tresky

Since 1980 the name TRESKY stands for the highest quality, unmatched flexibility with maximum reliability.

Tresky GmbH is one of the world’s leading machine manufacturers for placement systems in the high-precision sector offering more than 40 years of experience in the semiconductor industry. The company is headquartered in Hennigsdorf near Berlin, in the middle of a technology park that is home to numerous highly specialized companies from the automation, electrical engineering, communications technology and life science sectors. Quality “Made in Germany” – Tresky develops, produces and sells Die Bonders from its headquarters in Hennigsdorf. More information: www.tresky.de/en.

![NEPCON JAPAN [September] 2025 to Welcome 26,000 Trade Visitors and 350 Exhibitors at Makuhari Messe NEPCON JAPAN [September] 2025 to Welcome 26,000 Trade Visitors and 350 Exhibitors at Makuhari Messe](https://smttoday.com/wp-content/uploads/2025/07/PR-16-218x150.jpg)