Tresky GmbH from Hennigsdorf near Berlin will present its newly developed pre-sintering processes at this year’s PCIM Europe in Nuremberg. As assemblies with high-performance semiconductors represent a key technology for the global energy turnaround and electromobility, Tresky has been working on these manufacturing processes for some time and will present further product and process innovations in 2023 as part of additional development steps.

“At PCIM Europe, we will present the pre-sintering process and the associated components we have developed to the German expert audience for the first time,” explains Daniel Schultze, Managing Director of Tresky GmbH. During the sintering process, the chip is not only electrically but also thermally very well bonded to the substrate by means of silver and copper paste. This is done with the help of heat and pressure. In this process, the silver or copper particles are bonded together by diffusion processes. “The advantage over normal soldering processes is the very high thermomechanical stability, which is particularly needed in power electronics,” Schultze continues.

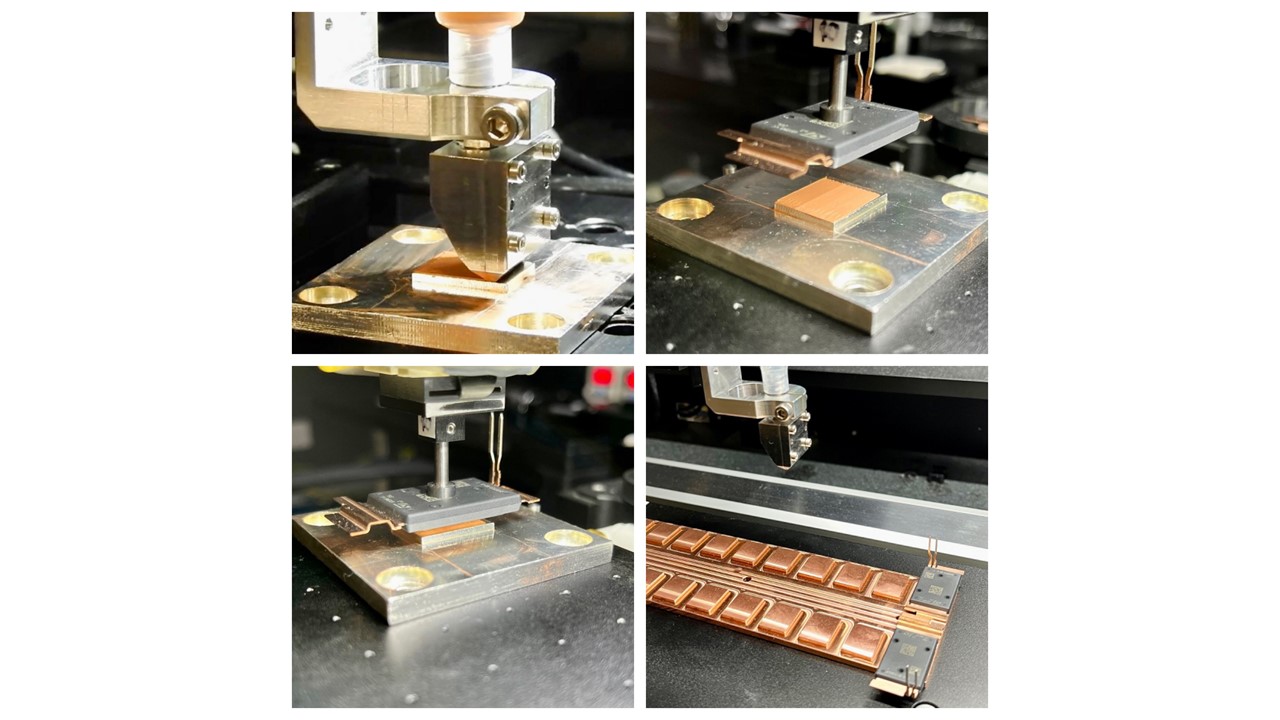

“The service life and energy efficiency of these assemblies essentially determine the efficiency and economic success of the process in which the assembly fulfils its function. State-of-the-art assembly and connection technology is the solution to today’s problems in the production of power electronic assemblies,” Schultze continues. In copper and silver sintering, the paste application and the application of the semiconductor are the most important process steps. “We have developed a process that combines these two important steps, the sequential two-dimensional application of the Cu or Ag sintering paste to the substrate and the placement of the power semiconductor in one machine,” Schultze continues. This combination, paired with the already established Tresky process modules, enables a cycle-time-optimised production in which reproducible results are guaranteed.

Furthermore, the sintering process can be combined with additional options, such as processing wafers, pressing components with high pressure as well as dispensing a tacking agent that supports the positioning and fixation of the DIE on the substrate provided with sintering paste.

From 09 to 11 May 2023, Tresky will present itself at PCIM Europe in Nuremberg in Hall 6, Booth 434.

About Tresky

Since 1980 the name TRESKY stands for the highest quality, unmatched flexibility with maximum reliability.

Tresky GmbH is one of the world’s leading machine manufacturers for placement systems in the high-precision sector offering more than 40 years of experience in the semiconductor industry. The company is headquartered in Hennigsdorf near Berlin, in the middle of a technology park that is home to numerous highly specialized companies from the automation, electrical engineering, communications technology and life science sectors. Quality “Made in Germany” – Tresky develops, produces and sells Die Bonders from its headquarters in Hennigsdorf. More information: www.tresky.de.