Yxlon presented the new release of the Cheetah and Cougar EVO microfocus X-ray families in three online events. Under the motto ‘Innovation is key to Evolution – Evolution empowers you’, the next step towards automation was demonstrated and new options were presented that significantly increase efficiency in the X-ray inspection of electronic components.

Laminography with micro3Dslice in the Yxlon systems is not new but the visualization with the FF CT software, which is now integrated as standard, means 3D images of a new level of brilliance and detail. At the same time, the software remains compatible with Volume Graphics and the corresponding analysis tools.

Concurrently, a new high-resolution flat-panel detector, the ORYX 1616 with a size of 1280 x 1280 pixels, has been introduced that offers a field-of-view extension of 50% compared to the standard version. This means a much better overview and faster work processes due to reduced work steps in automatic sequences. The optimized electronics of the detector enable higher speed and better stability in 24/7 use. Moreover, the ORYX 1616 not only has an improved radiation resistance but can also work with a much lower radiation dose due to its sensitivity. For particularly sensitive test parts, Yxlon also offers the Dose Reduction Kit to reduce X-ray radiation to the absolute minimum and thus protect the test parts even better.

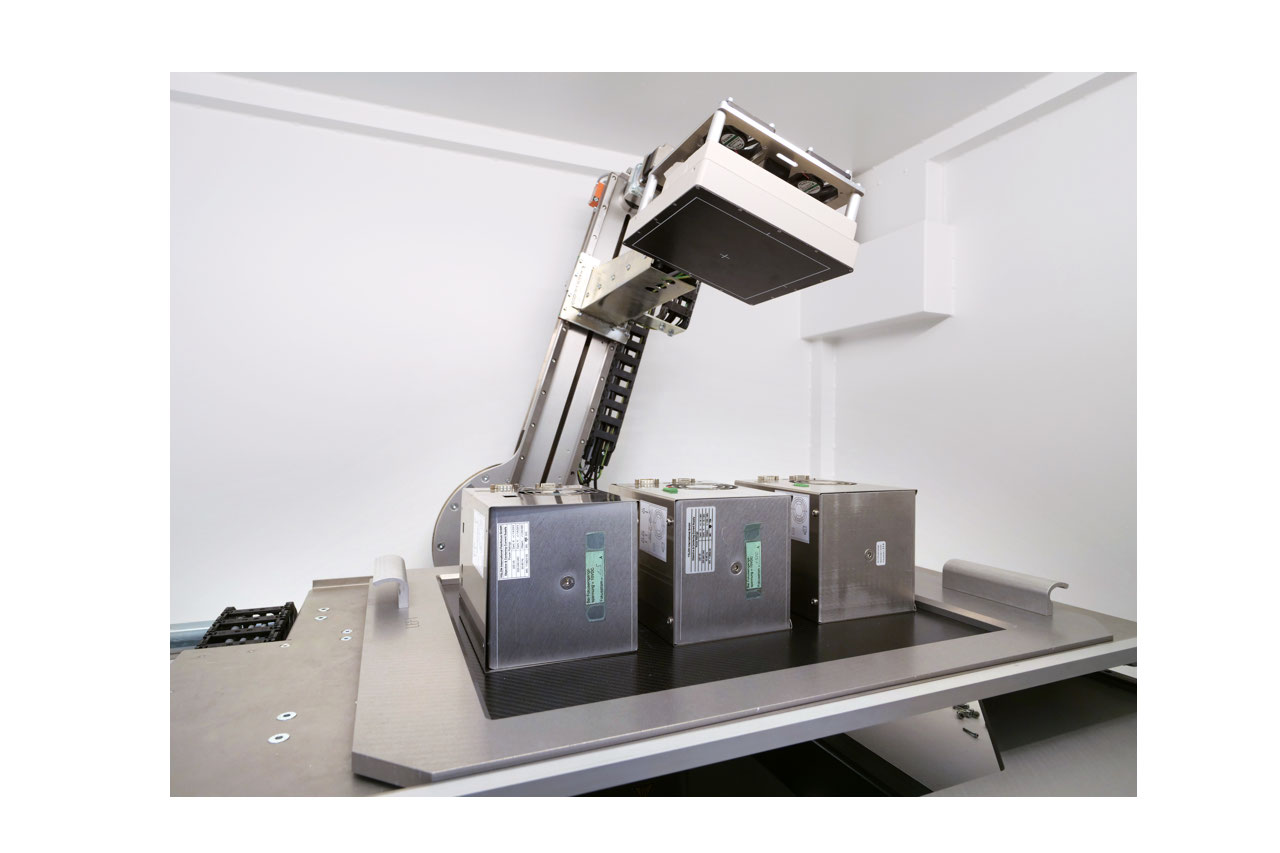

Another highlight is the optional High Load Capacity, a loading unit that, thanks to its special mechanics, can manipulate even multiple or heavy parts weighing up to 20 kg easily, precisely, and without interference. It finds particular use in the inspection of electronics within a closed housing, as is increasingly the case with electric vehicles, for example, or in the efficient check of multiple parts in a single test process.

The YXLON Cheetah and Cougar EVO families in their specific

configurations are specially used in the SMT and Semicon sector when the Plus variants mainly support laboratory applications in research and development.

About YXLON

YXLON International, a company of the Swiss Comet Group, designs and produces radioscopic and CT inspection systems for the widest variety of applications and fields. Whether situated in the aviation & aerospace, automotive or electronics industry, our customers are among the largest producers, major enterprises that place their confidence in our quality worldwide.

The name Comet YXLON stands for assurance and quality for all types of cast parts, tires, electronic components, turbine blades, welded joints and a lot more. Whether in manual, semi or fully automated operation, our inspection systems support the production and are ideal for deployment in research & development.

With our FeinFocus product line we offer microfocus systems for detailed insights into finest structures. In the fields of semiconductor packaging, SMT applications, for the verification of sensors, relays, and many more – with 2D or 3D inspection, missing or damaged bonding wires, flawed soldering joints or splices as well as other manufacturing defects can reliably be detected and their position and size defined according to requirements. Moreover, the generated data provide important feedback about the production processes allowing their immediate corrections.

With our headquarters in Hamburg, sales and service locations in Hudson (Ohio), San Jose

(California), Yokohama, Beijing, Shanghai, and Taipeh as well as a network of representatives in over 50 countries, as YXLON we’re local for our customers all over the world.