SGS, the world’s leading testing, inspection and certification company, has today announced its membership of the Automotive Electronics Council (AEC), the organization that sets qualification standards for electronic components in the automotive industry.

Joining as an associate member of AEC’s Technical Committee, SGS will participate in the improvement and development of the verification standards for the automotive semiconductor industry.

Candy Lau, Reginal Director, Connectivity & Products at SGS said “As a global company committed to enabling a better, safer and more interconnected world, we are delighted to join the AEC. Working alongside fellow members, we look forward to taking an active role in the improvement and development of the verification standards for the automotive semiconductor industry.

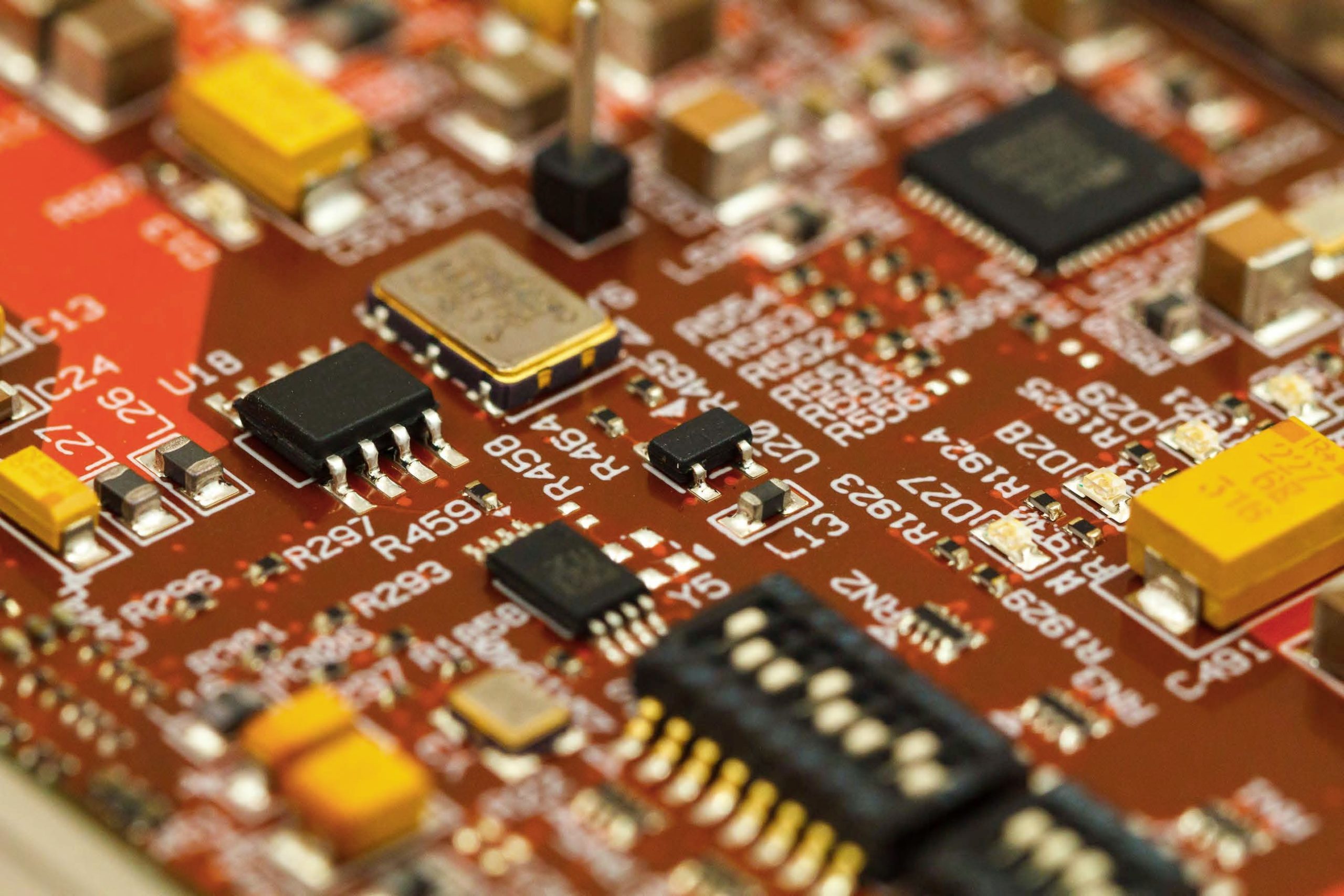

“Semiconductors are now critical components in the modern day automotive, widely used in the areas of electrification, control, safety, connectivity and infotainment. By increasing the semiconductor contents in vehicles, we can help to speed up the electrification and other advances in the automotive industry.”

AEC membership reflects SGS’s leading role withing the automotive semiconductor industry for the testing and verification of products based on AEC-Q standards.

In the early 2000s, SGS’s semiconductor lab in Dongtan, Korea, started reliability services for automotive electronics and soon expanded to the services of automotive semiconductor reliability test and failure analysis. This contributed not only to the development of the automotive industry but also to imported semiconductor re-verification for Korea’s leading automotive companies.

Today, SGS’s global semiconductor testing laboratories cover the full spectrum of AEC-Q standards testing services, including AEC-Q100 (Integrated Circuits), AEC-Q101 (Discrete Semiconductors), AEC-Q102 (Optoelectronic Semiconductors), AEC-Q103 (Sensors), AEC-Q104 (Multichip Modules), AEC-Q200 (Passive Components) as well as comprehensive failure analysis and materials analysis for development and improvement of automotive semiconductors.

SGS’s automotive services center in New Taipei City, provides a total solution for the automotive supply chain, including product design, process design, product and process validation; as well as testing, inspection, verification and certification for each of these stages. Besides providing AEC-Q200 testing service for passive components, SGS also provides Alpha particles (radiation) testing to prevent soft error fault based on JESD 89B standard per the requirement of AEC-Q100.

In Shenzhen and Suzhou, SGS’s two semiconductor testing labs are helping to meet the increasing demands of AEC-Q testing and related failure analysis and material analysis services for the region’s fast-growing automotive industry.

SGS also supports the major automotive semiconductor supply chain across Europe. The SGS INSTUTUT FRESENIUS in Dresden, Germany, provides analytical services for microelectronics and related high-tech industry and is one of the leading providers of analytical services along the value chain of the high-tech industry in Germany, specializing in material, surface and nano-structure analyses.

Recent developments have seen SGS’s advance new analytical techniques for failure analysis of automotive components under harsh environmental conditions to enable better understanding of environmental factors on the reliability of semiconductor components; progressing “zero failure rate” required in the automotive industry.

For more information, please visit www.sgs.com