With circuit board plotters and laser systems for research and development, LPKF offers a comprehensive range of equipment for manufacturing printed circuit board prototypes. If a prefabricated circuit board is then to be turned into an electronic assembly, SMT manufacturing is added to that. LPKF has now renewed and expanded its portfolio for the processes of solder paste printing, assembly with SMD components, and reflow soldering.

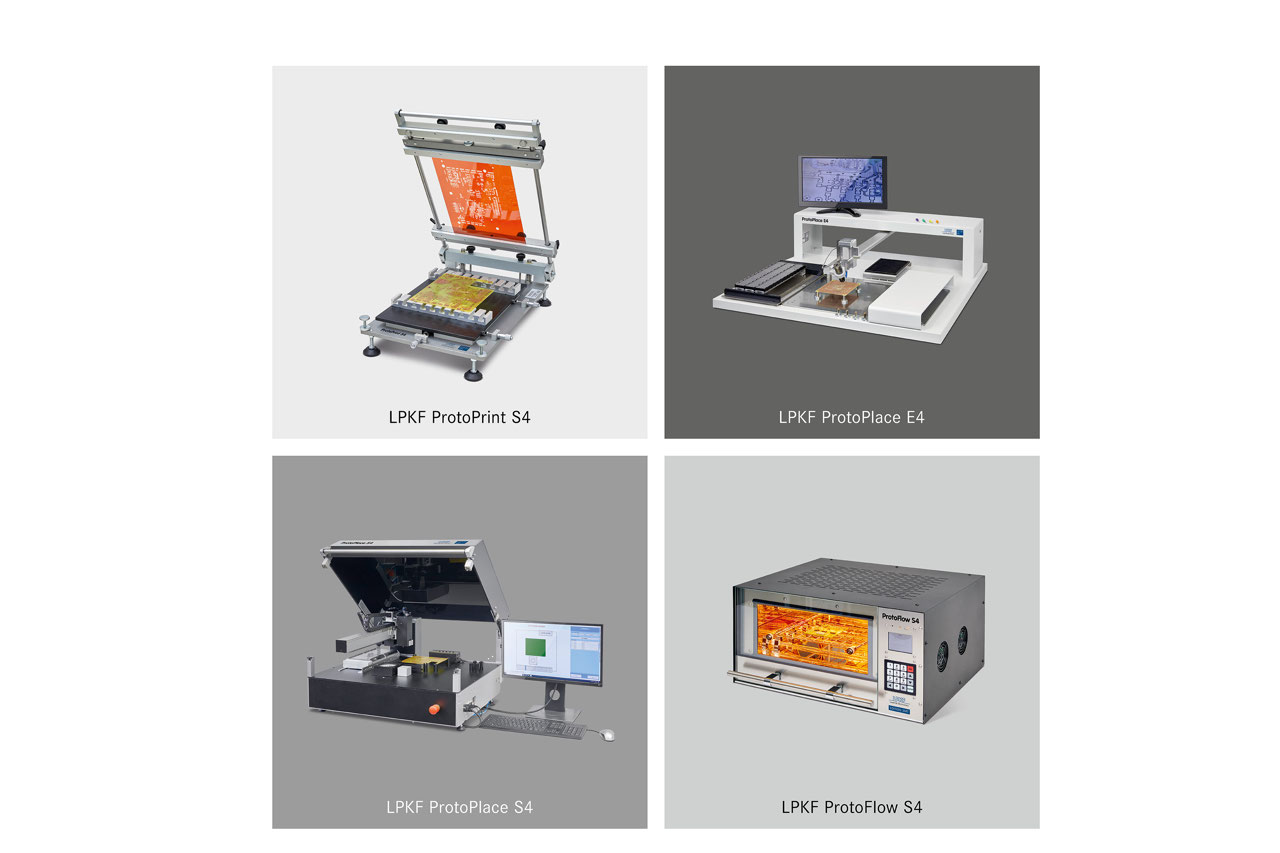

The LPKF ProtoPrint S4 is a manual stencil printer for achieving precise printing results. The device is suitable for single-sided and double-sided printing of PCB prototypes and low volumes. Thanks to the integrated size-adjustable clamping frame, the ProtoPrint S4 can use polyimide film or stainless steel stencils.

Mounting of tiny SMDs on prototype boards is supported by the LPKF ProtoPlace E4. The components are safely removed from the component trays or tape feeders with the manual pick & place system, guided to the appropriate places above the circuit board with an ergonomically formed placement head, and placed – all very easily with just one hand.

If large numbers of components or low volumes need to be mounted repeatedly and comfortably on boards, the LPKF ProtoPlace S4 pick & place machine is the go-to system. It can be used flexibly for various chip designs and features camera support for a very high precision. The system has an automated nozzle changer with 6 nozzles and an intuitive graphical user interface and is equipped with a CAD editor for nearly all CAD systems.

The compact LPKF ProtoFlow S4 hot-air oven is the ideal device for the subsequent RoHS-compliant lead-free reflow soldering. Thanks to the PC-based user software, it is very easy to use. The oven features a LAN interface for remote operation, a large viewing window for monitoring the melting process, and active process chamber cooling. An additional temperature sensor is optionally available.

With this equipment, all processes and methods of automated SMT mass production are also available for in-house PCB prototyping – adapted to the requirements in the electronics laboratory. In just a few steps, the low-cost, proven methods lead to an electrically functional product created with high precision.

LPKF provides further information about PCB prototyping and SMT manufacturing in its virtual showroom. On this portal, users can find out more about the individual process steps, watch videos of the prototyping process, and access information about the respective products. The showroom is divided up into four main topic areas: PCB Basic Line, Multilayer Production, RF Prototyping, and Micromaterial Processing. It is available at https://product-showroom-dq.lpkf.com/.