KOKI Company Limited (Tokyo, Japan) is pleased to announce the release of new solder pastes for low temperature reflow soldering processes designed for printing and dispensing applications.

From the viewpoint of power consumption reduction and electrical reliability of an assembly as a whole, there has been a persistent demand for low-melting temperature solder paste for some time. To meet such demands, several Sn-Bi based alloy products are already out and available in the market.

Conventional Sn-Bi solder pastes often contain large amounts of relatively strong activator to secure

meltability and coagulation equivalent to that of SAC305. If the heat applied is not sufficient and leaves the activator as residue, the residue could pose a reliability concern. Even if the solder paste is designed so that the solvent will evaporate easily for better insulation resistance, it has a trade-off as the solder paste may dry up too fast, negatively affecting the paste printing, viscosity, and tackiness properties.

The newly introduced solder pastes T4AB58-HF360 for printing and T4AB58-HF360D for dispensing adopt an optimized amount of a carefully selected activator that effectively facilitates the reduction-oxidation reaction, thereby minimizing the amount of the added flux activator while securing excellent meltability and coagulation. This not only improves the insulation resistance, but also helps to achieve stability in continual application and in holding and securing components in place during and after the component placement process.

Sn-Bi based low-melting temperature solder paste designed for air reflow

The alloy composition of T4AB58-HF360 and T4AB58-HF360D is Sn, 0.4Ag, and 57.6Bi with the melting temperatures from 138 to 140 degrees Celsius, suitable for soldering heat-sensitive components and PCBs in an air atmosphere.

Newly adopted technology prevents paste dry out and achieves stable application performance

The new technology works to keep the solder pastes from drying too quickly for stable performance in continuous application of the product. It also helps to hold a placed component in position during and after the placement process.

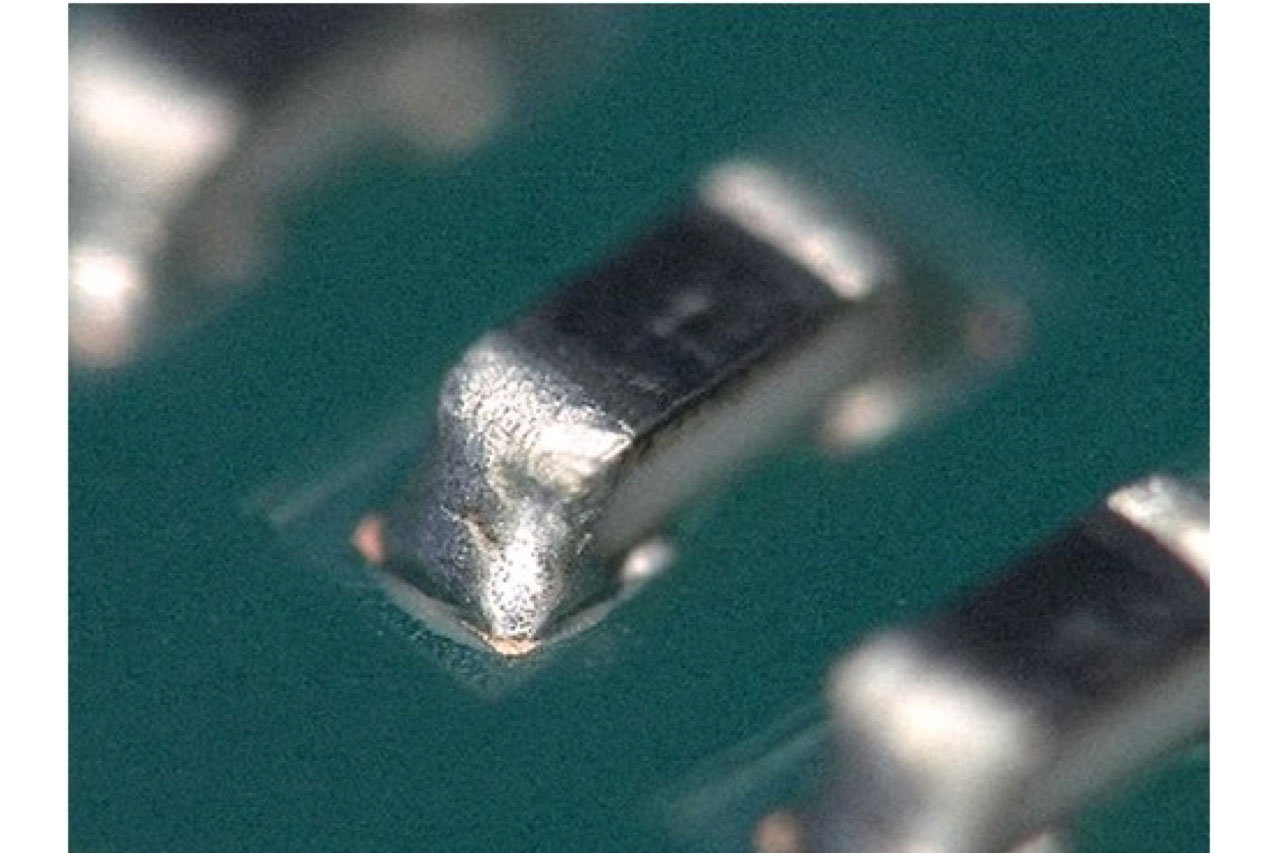

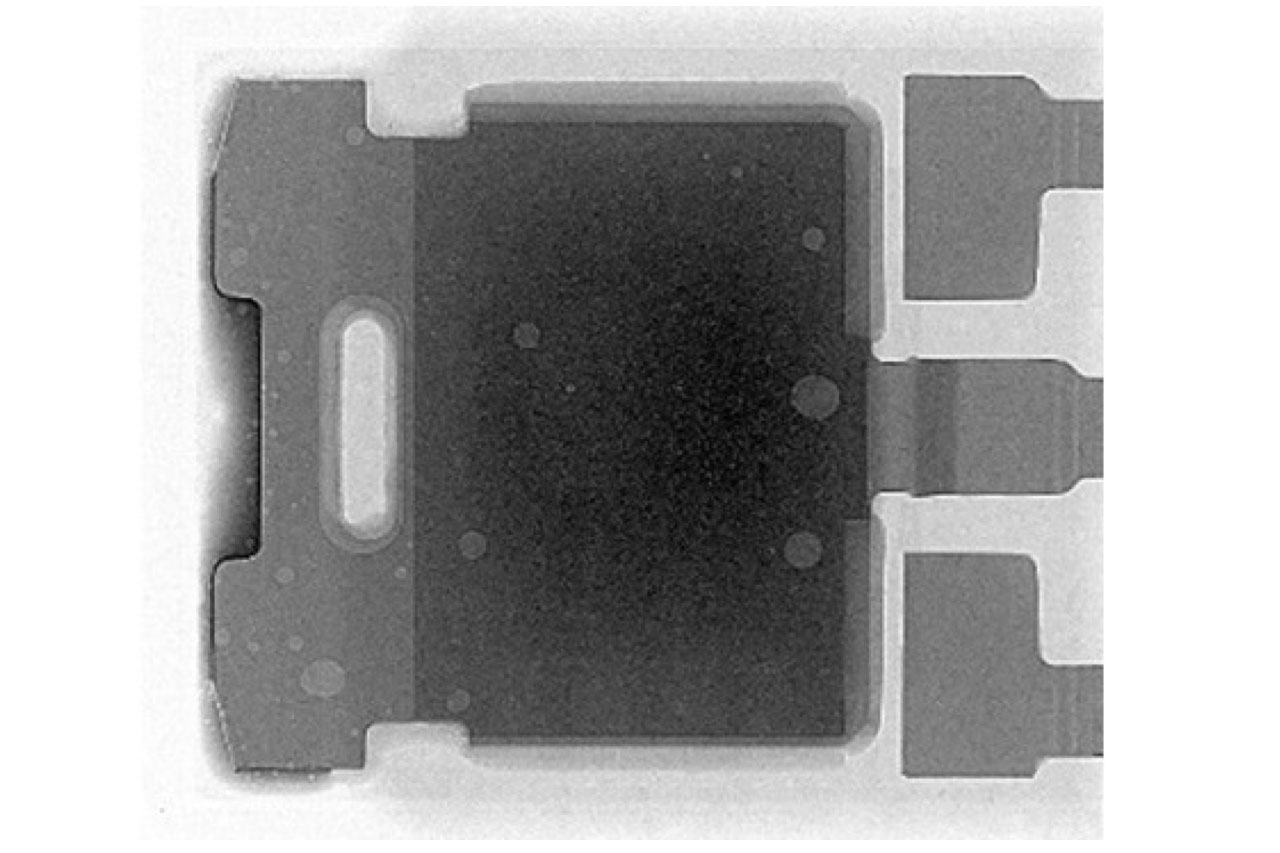

Achieve excellent wettability and low-voiding

T4AB58-HF360 and T4AB58-HF360D exhibit excellent meltability, wettability and coagulation owing to the activator that works effectively with Sn-Bi based solder. The resulting solder joints have low voiding.

[Product Outline]

T4AB58-HF360, T4AB58-HF360D

Alloy composition – Sn 0.4Ag 57.6Bi

Melt point – 138 – 140

Flux type – ROL0*

Particle size (μm) – 20 – 38

*According to IPC J-STD-004B

For inquiries contact: KOKI Company Limited

E-mail: support@ko-ki.co.jp