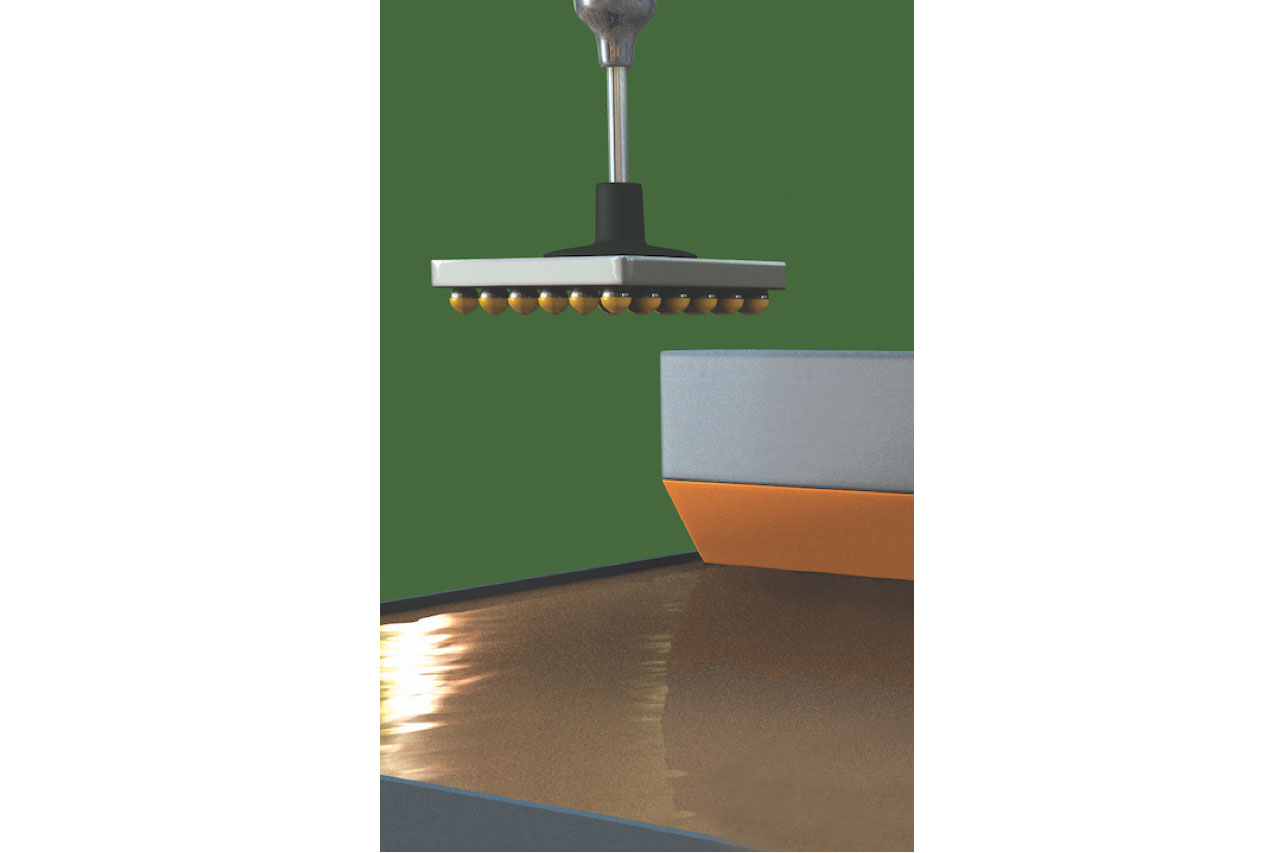

Indium Corporation continues to expand its flux portfolio with WS-823—a proven, one-step ball grid array (BGA) ball-attach flux designed to eliminate the costly and warpage-inducing prefluxing step, especially on Cu-OSP substrate.

While the standard ball-attach process requires two steps, especially on a Cu-OSP substrate, WS-823 is a halogen-free, water-wash flux designed for a single-step ball-attach process that eliminates the prefluxing step in order to create reliable ball-to-pad joints.

WS-823 provides:

- Tackiness suitable for holding solder spheres in place during reflow

- Excellent solderability on a wide range of surfaces, including AuNi and oxidized Cu-OSP

- Uniform pin transfer over extended periods, eliminating changes in joint quality over time and uneven deposit sizes, which can lead to “missing ball”

- A formula engineered for low-voiding, thereby increasing joint strength

- Good cleanability with room temperature DI water, avoiding the formation of white residue

For more information on WS-823, and other materials in Indium Corporation’s ball-attach flux portfolio, visit indium.com/ball-attach