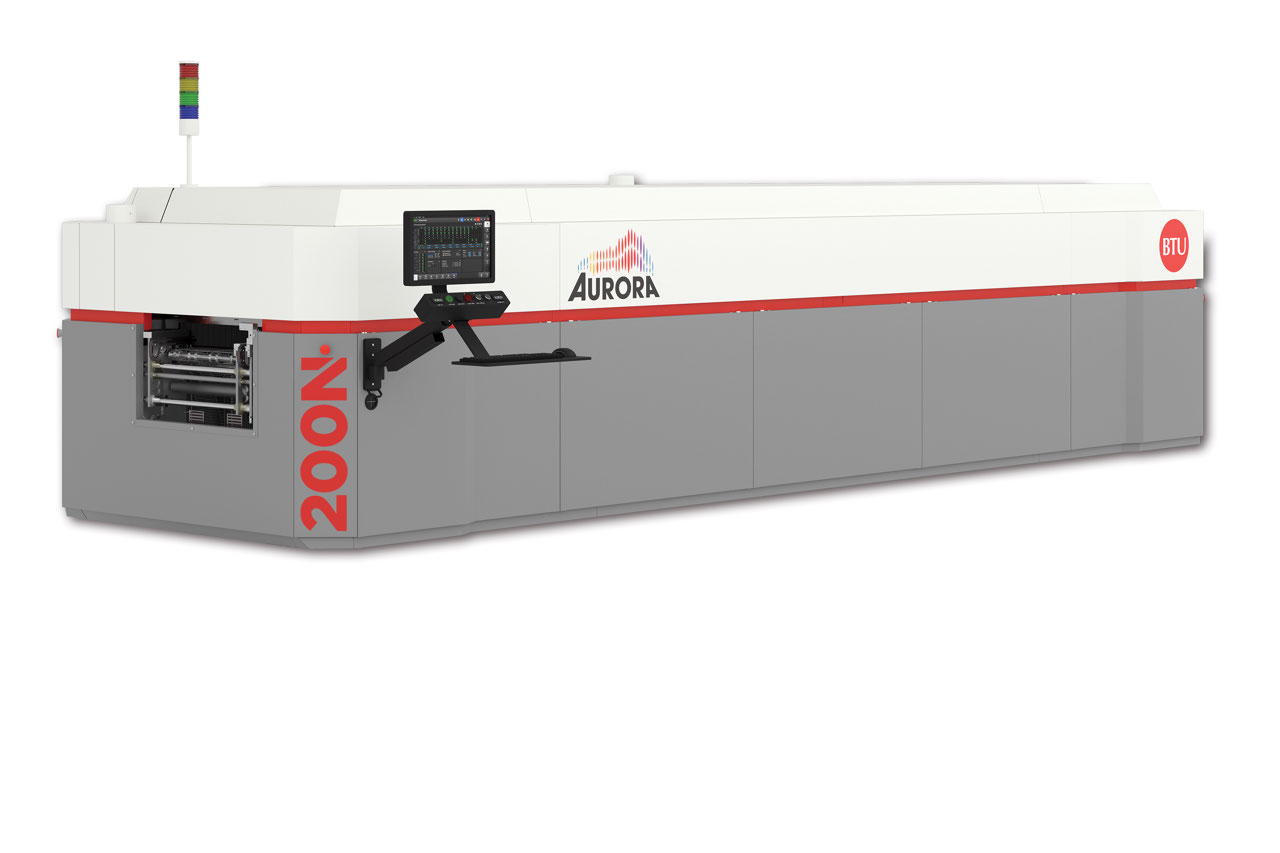

BTU International, Inc., a leading supplier of advanced thermal processing equipment for the electronics manufacturing market, is pleased to announce that its Aurora 200N Reflow Oven has been honored with a 2025 Global Technology Award in the category of Soldering Equipment – Reflow. The award was presented during a ceremony at productronica in Munich, Germany, on Tuesday, November 18, 2025.

The Aurora 200N is BTU’s most advanced reflow oven to date—and the longest in the company’s history—offering 200 inches of heated length to support production line speeds up to 25% faster than previous models. Its extended configuration allows manufacturers to achieve high-throughput production goals while maintaining thermal process integrity. The modular design allows the oven to be shipped in two sections for simplified delivery and installation, without compromising performance.

“We designed the Aurora 200N to give manufacturers the speed and precision they’ve been asking for—without adding complexity,” said Rob DiMatteo, General Manager of BTU International. “Winning this award at productronica confirms that Aurora is hitting the mark, helping our customers build more efficiently and stay ahead of production demands.”

Aurora 200N Highlights:

• 200 inches of heated length for maximum throughput

• Flexible heating and cooling zone configurations for process adaptability

• Smart Power™ energy-saving software to reduce operating costs

• Updated Wincon™ software interface for modern process control

• Integrated Aqua Scrub™ flux management system for cleaner operation

• Advanced conveyor options for improved board handling and line integration

Designed for high-reliability applications across automotive, aerospace, and industrial electronics sectors, the Aurora 200N combines speed, efficiency, and robust process control to help manufacturers increase productivity and maintain consistent, repeatable results.

About BTU International

BTU International, a wholly-owned subsidiary of Amtech Group (Nasdaq: ASYS), is a global supplier and technology leader of advanced thermal processing equipment in the electronics manufacturing market. BTU’s high-performance reflow ovens are used in the production of SMT printed circuit board assemblies and in semiconductor packaging processes. BTU also specializes in precision controlled, high-temperature belt furnaces for a wide range of custom applications, such as brazing, direct bond copper (DBC), diffusion, and sintering. BTU has operations in Westford, Massachusetts, and Shanghai, China, with direct sales and service in the U.S.A., Asia and Europe.