PEMTRON, an inspection equipment developer and supplier, will showcase its latest breakthroughs in semiconductor and electronics inspection in Booth L406 at the KPCA Show 2025 (International Electronic Circuits and Packaging Show), held September 3-5, 2025 at Songdo Convensia in Incheon, Korea.

Visitors to PEMTRON’s booth will experience two of the company’s most advanced systems in action: the POSEIDON Wafer Warpage Measurement System and the JUPITER 3D X-ray Inspection System (AXI)—each designed to boost quality, yield, and efficiency in high-stakes production environments.

POSEIDON: Precision Wafer Warpage and Bump Inspection for Demanding Applications

The POSEIDON system delivers highly accurate measurement of wafer warpage, flatness, and FC-BGA bump coplanarity—critical for processes like wire bonding and Micro LED assembly. It also captures fine surface defects, including microcracks, missing bumps, and bridging. With fast 3D data acquisition and real-time analysis, POSEIDON helps manufacturers maintain tight process control and prevent early-stage defects from impacting downstream production.

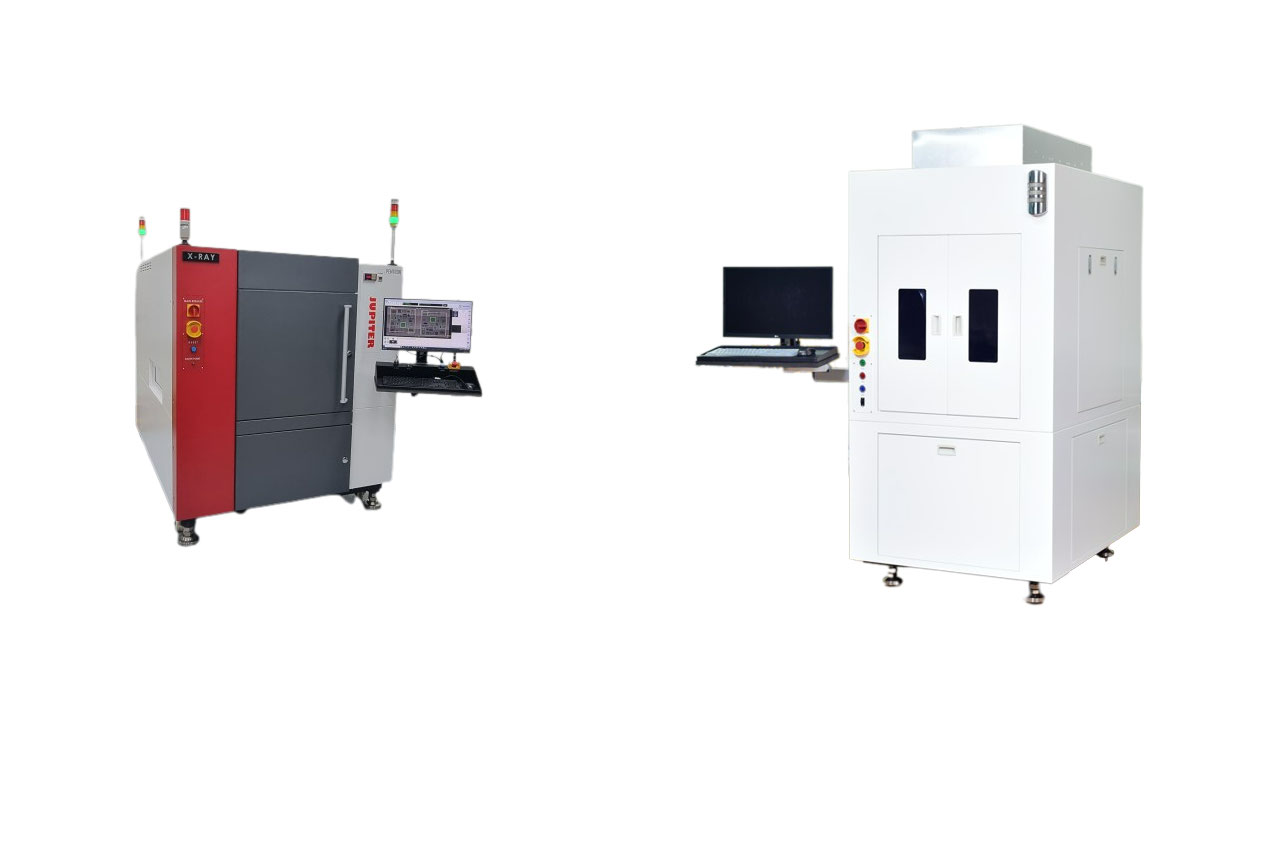

JUPITER: Deep X-ray Insight for Smarter Process Control

JUPITER features cutting-edge 3D X-ray imaging powered by PCT reconstruction, providing a detailed view of internal structures, including solder joints and die attachments. Combined with PEMTRON’s proven AOI defect detection software and high-resolution optics, JUPITER enables comprehensive 2D/3D inspection in one platform. Its ability to integrate with SPI and AOI systems offers real-time insight into defect patterns and production trends—accelerating response times, reducing waste, and improving overall process stability.

Both systems will be on display at KPCA Show 2025, where attendees can engage with PEMTRON’s technical team and see how these solutions deliver measurable improvements in quality assurance and productivity.

About PEMTRON

Based on 3D precision measurement and vision source technology, PEMTRON develops equipment used in various fields such as SMT, Automotive Field, Lead Tab, Semiconductor, and supplies Soldering Inspection equipment (3D SPI), 3D Mounting Inspection equipment (3D AOI, MOI), Conformal Coating Inspection equipment (TROI-8800 CI), Bottom Head Inspection equipment (Eagle 8800TH), Top & Bottom Double Sided Simultaneous Inspection equipment (Eagle 8800TWIN), Automated X-Ray SMD Counter (MERCURY), Wafer Sawing Before/After 3D Inspection equipment (8800 WI/WIR), Wire Bonding 3D Inspection & MEMS Auto Inspection equipment(ZEUS), Package AVI equipment (APOLLON), Memory Module / SSD Auto Inspection equipment (MARS), FC-BGA, FCP-CSP Inspection equipment (POSEIDON-S), Scale Sorter Of FC-BGA Products (8800 FI), Bump Metal Mask Inspection equipment (8800 MI), PCB Appearance Inspection equipment (8800 AI) and Lead Tab Process/Inspection equipment(Hawk 7300).