Market and technology leader ASMPT is offering a new stationary camera available for its placement machines equipped with SIPLACE placement heads CPP and TWIN. It delivers significantly faster processing speeds as well as more component flexibility – from highly integrated ball grid arrays (BGAs) to large-format odd shape components (OSCs).

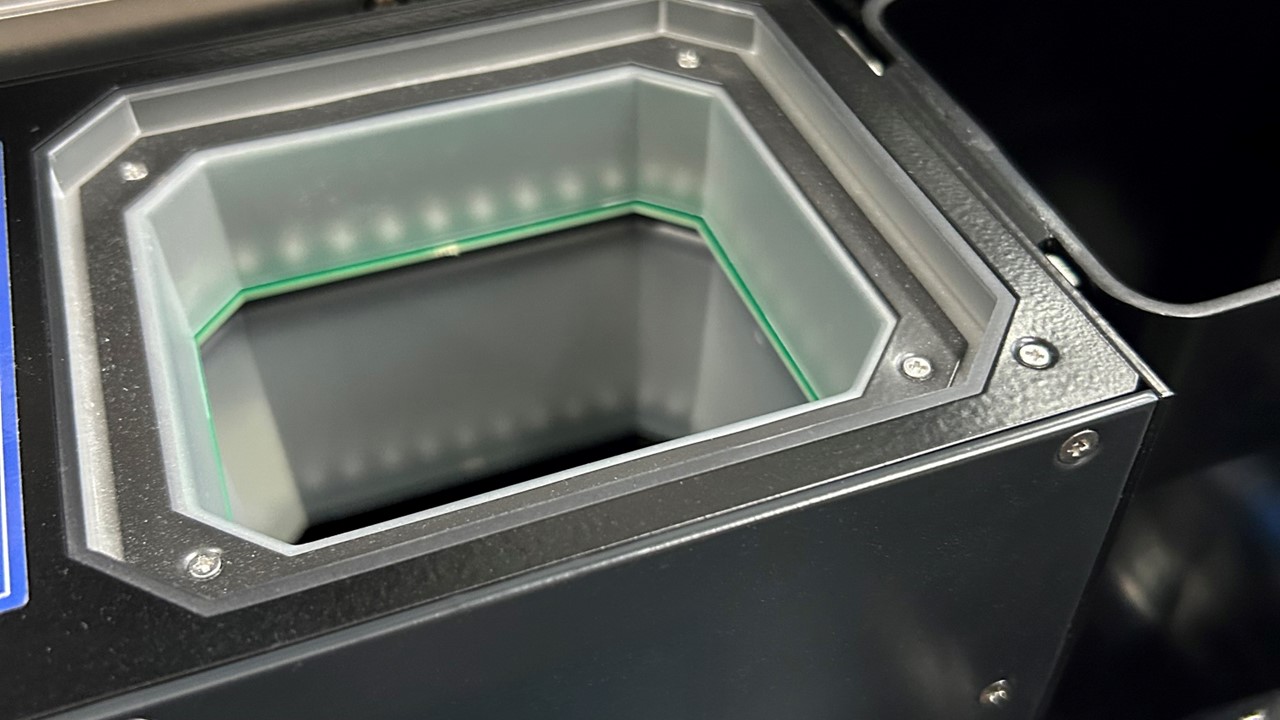

Effective immediately, SIPLACE placement machines with SIPLACE placement heads CPP and TWIN can be equipped with the new camera model 56, which features a detection area of 66 × 50 mm and a resolution of 16.2 microns per pixel.

Advantages at both ends of the size scale

Thanks to its high resolution, the new camera offers clear quality improvements because it can detect balls with diameters of 80 microns. For complex BGA structures like those on AI chips, the new camera delivers images with six times more pixels per ball than the conventional system, making it much easier to detect faults. At the other end of the size scale, the camera’s high resolution enables significantly faster and more accurate stereoscopic measurements of special components, which makes the new camera system particularly attractive for the automobile industry.

Retrofits are easy

“Our new stationary camera, which can be easily retrofitted, delivers significant advances in quality, performance and component flexibility for electronics manufacturers,” explains Sven Buchholz, Vice President Portfolio Management at ASMPT SMT Solutions. “It enables them to process even highly detailed BGAs reliably and move many complex OSCs from manual to machine-based placement.”

Superb synergy with SIPLACE placement heads

In combination with SIPLACE placement heads, the new stationary camera delivers outstanding results in terms of speed and flexibility. The highly flexible, software-controlled SIPLACE CPP head adapts easily to varying requirements by switching seamlessly between its three placement modes: collect-and-place, pick-and-place, and mixed mode. Thanks to this capability, lines can stay perfectly balanced even during frequent product changeovers with no time-consuming configuration or head changes. The SIPLACE TWIN head, on the other hand, is a high-precision pick-and-place twin head that was specially developed for the end-of-line placement of large, heavy and complex components. The TWIN VHF version of this head can place components weighing up to 300 g with precisely adjustable forces of up to 100 N.

To learn more, www.asmpt.com.