Heraeus Electronics is pleased to announce its participation at SMTA International, a premier event for electronics manufacturing and assembly professionals. The event is scheduled to take place Oct. 9-12, 2023 at the Minneapolis Convention center in Minneapolis, MN. Heraeus Electronics will present its groundbreaking Microbond® SMT660 Innolot and Microbond® SMT660 Innolot® 2.0 Solder Pastes, and showcase its exceptional sinter paste innovations, including the PE338 Silver and PE401 Copper Pressure Sinter Paste in Booth #1230.

Redefining Reliability and Cost Efficiency

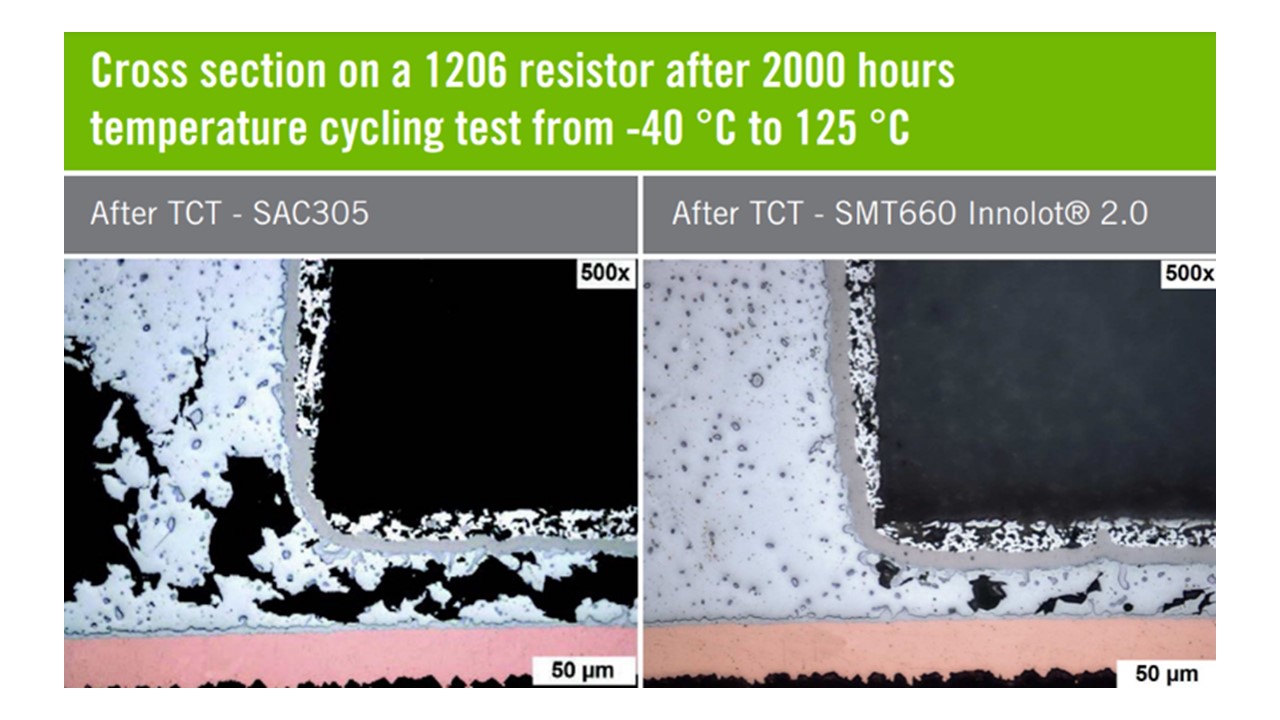

Heraeus Electronics is revolutionizing the automotive industry with its Microbond® SMT660 Innolot® 2.0 solder alloy. This advanced solution offers an innovative approach to highly reliable and cost-effective solder alloys for automotive applications. By introducing the ability to maintain a competitive Total-Cost-of-Ownership (TCO) while meeting emerging requirements, Heraeus Electronics is setting new industry benchmarks. The next generation of Innolot® alloy enhances creep resistance, leading to extended product life cycles at higher operating temperatures. Notably, the Microbond® SMT660 Innolot® 2.0 solder paste excels in reflow without the need for additional N2, keeping defect rates low and reducing TCO.

Advancements in Flux Design for Enhanced Performance

The Microbond® SMT660 solder paste incorporates a flux designed to deliver superior performance. An acrylic-based synthetic resin eliminates potential batch-to-batch variations often associated with natural raw materials. This approach, combined with low impurities, results in a high Surface Insulation Resistance (SIR) performance, reducing the risk of electrochemical migration. This flux combined with Innolot® or Innolot® 2.0 alloy synergy offers exceptional reliability, making it especially valuable in miniaturized systems within the automotive industry.

Focus on Sinter Paste Innovations

During the event, Heraeus Electronics also will showcase its cutting-edge sinter paste innovations. The PE401 Copper Pressure Sinter Paste represents a breakthrough material for die attach applications of high-power packages. Known for forming highly reliable joints with excellent thermal conductivity, PE401 is both lead-free and devoid of halogens and nano particles.

The mAgic Pressure Sinter Paste PE338 and PE338 F1510 Sinter Pastes for stencil and screen printing improve device reliability and provide high electrical conductivity, improving device efficiency. The pastes have proven to enhance workability on copper surfaces and elevate performance longevity by integrating wide band gap materials such as SiC and GaN.

To learn more about Heraeus Electronics, visit www.heraeus-electronics.com.