Heraeus Electronics is excited to announce its participation in SEMICON China, scheduled to take place June 29 – July 1, 2023 at the Shanghai New International Expo Center (SNIEC). Heraeus Electronics will showcase its innovative range of semiconductor packaging materials and printed electronics in booth E7355, Hall E7.

Delivering compact yet powerful electronic devices

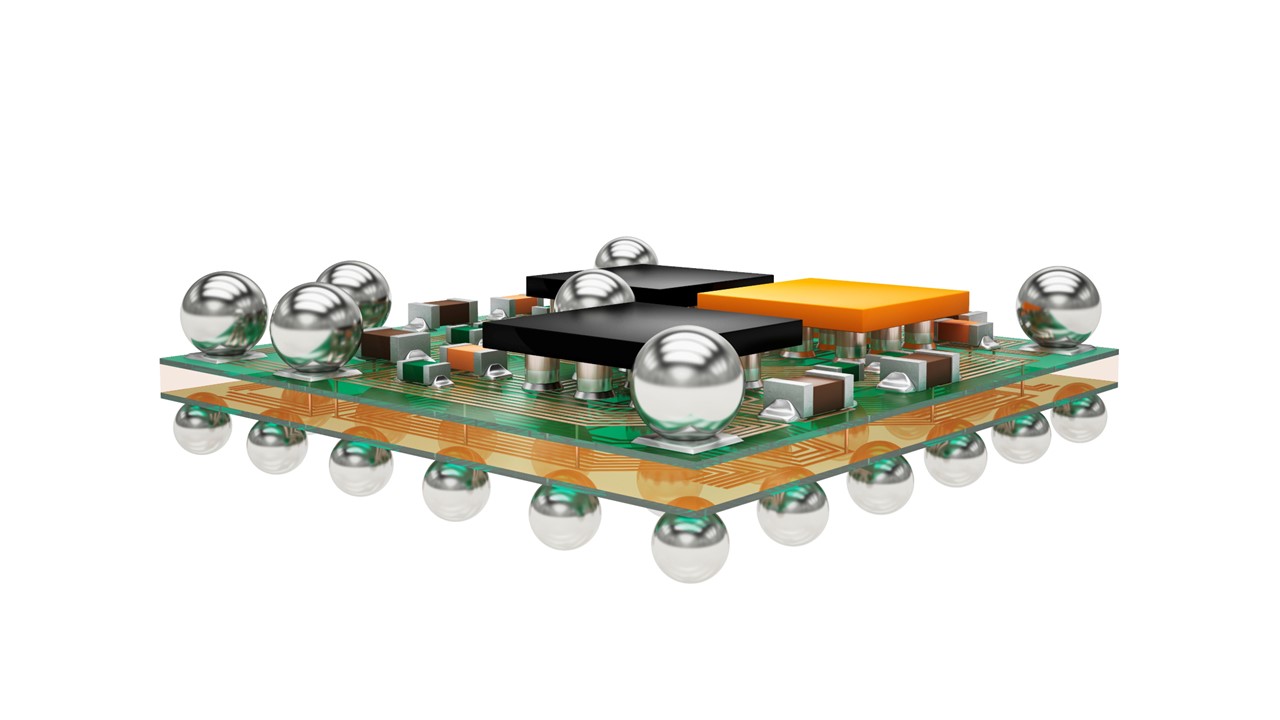

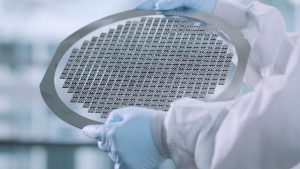

The semiconductor advanced packaging industry is at the forefront of meeting the growing demands for highly sophisticated and intricate electronic products utilized in a wide range of applications, including 5G communications, Internet of Things (IoT), augmented reality (AR), smart wearables, electric vehicles, and various consumer and industrial sectors. With a relentless focus on achieving superior performance and compactness, the industry is continuously pushing the boundaries by increasing the component density within semiconductor packages, such as the system-in-package (SiP), while simultaneously reducing the overall package size.

Heraeus Electronics’ solution:

Welco AP520: This state-of-the-art water-soluble type 7 printing paste is designed to solve the challenges of miniaturization, as it can create tiny and reliable joints with close to zero defects. With excellent paste release down to 90 µm pitch (55 µm stencil opening and 35 µm line spacing), no splashing and best-in-class low void performance, AP520 makes an excellent choice for fine-pitch components and flip chip attach for next-generation System-in-Package applications used in 5G communications, smart-wearables, and electric vehicles.

Development of defect-free HPC systems

High-Performance Computing (HPC) has become increasingly integral to everyday life, powering a range of applications including processors for Artificial Intelligence (AI), gaming computers and consoles, 5G smartphones, autonomous driving systems, memory controllers, and more. The key enabling technology for HPC lies in high bump-count and fine bump-pitch flip chips, which require reliable soldering onto substrates. However, the semiconductor industry faces significant challenges in eliminating defects such as cold joints, solder creeping, die shifting, voiding, underfill delamination, and others.

Heraeus Electronics’ solution:

AP500X: This water-soluble, halogen-free tacky flux is specifically engineered for ultra-fine bump-pitch flip chip attach and BGA attach applications. This new carefully designed flux plays an important part in eliminating defects such as cold joints, solder creeping, die shifting, voiding, underfill delamination, etc. in advanced semiconductor packages for high performance computing, memory, mobile and more.

Heraeus’ solution for EMI shielding in 5G technology

Offering accurate selective coating without any masking is the key benefit of the Prexonics® full system solution for EMI shielding on package level. This new technology is the first to enable a thickness aspect ratio of 1:1 at topside and sidewalls and thus only 1.5-2μm conductive film on topside is needed to achieve the required shielding performance. Prexonics® is a unique full system solution offered by Heraeus Printed Electronics, that consists of a special particle-free silver ink, an inkjet printer, and a manufacturing process that uses inkjet printing to apply full, partial or trench coating. This approach allows selective and precise deposition of the silver ink onto specific areas of the component, avoiding excess material and minimizing waste. By using the specialized silver ink customized thin metallization films are possible in the range of 150nm to 4µm.

Offering accurate selective coating without any masking is the key benefit of the Prexonics® full system solution for EMI shielding on package level. This new technology is the first to enable a thickness aspect ratio of 1:1 at topside and sidewalls and thus only 1.5-2μm conductive film on topside is needed to achieve the required shielding performance. Prexonics® is a unique full system solution offered by Heraeus Printed Electronics, that consists of a special particle-free silver ink, an inkjet printer, and a manufacturing process that uses inkjet printing to apply full, partial or trench coating. This approach allows selective and precise deposition of the silver ink onto specific areas of the component, avoiding excess material and minimizing waste. By using the specialized silver ink customized thin metallization films are possible in the range of 150nm to 4µm.

Finally, Heraeus Electronics will announce its extended product portfolio towards sustainability initiatives with gold bonding wire made with 100% recycled gold and Welco solder paste series made with 100% recycled tin. By incorporating recycled tin or gold into our products, Heraeus Electronics contributes to environmental sustainability, significantly reducing energy consumption and carbon footprint. The pastes formulated with recycled tin maintain the same level of quality as those made with primary tin. Both recycled and non-recycled gold undergo the same meticulous refining process before being transformed into final products, including gold wires and gold-coated silver bonding wires. This ensures the consistent composition & properties across our offerings. Both Heraeus Electronics’ gold and tin suppliers comply with Responsible Materials Initiatives (RMI) and ISO14021:2016.

The Heraeus team also will conduct five live booth presentations that will discuss the company’s newly launched products, and show how its latest materials can further elevate your device performance.

To learn more about Heraeus Electronics, visit www.heraeus-electronics.com