The electronics and semiconductor manufacturing industries face a number of challenges. Increasingly smaller structure sizes, rising demands concerning the power density, dependability and safety of electronic components, as well as new manufacturing technologies call for greater precision and higher levels of technical cleanliness. The growing shortage of skilled workers is reinforcing the trend toward automated work steps, including cleaning. Furthermore, specifications regarding sustainability and resource consumption are also becoming more stringent. The dry and scalable quattroClean snow jet technology meets all these demands. The sustainable cleaning process requires neither water nor energy-intensive drying and can be automated as required.

Whether smartphones, household appliances, automobiles, medical devices or even aerospace equipment – semiconductors, integrated circuits, and microchips are the basis of all these modern applications. During their manufacture, the components undergo complex processes that are becoming increasingly demanding due to rising requirements in terms of performance, product quality, and durability, as well as new manufacturing technologies such as advanced packaging. This applies not only to precision, but also to the degree of technical cleanliness that must be achieved. The benchmark is the level of cleanliness deemed necessary for subsequent processes or the end application. The limit values for residual particulate contamination are often in the submicrometer range, and for filmic organic and inorganic contaminants even in the nanometer range. The scalable quattroClean snow jet technology from acp systems AG has been proven to meet these sometimes extreme cleanliness requirements in series production in a dependable and reproducible manner. And this has been shown to be the case for a wide variety of full-surface or selective cleaning tasks, such as removing flux/solder residues or tiny particles, wafer dicing, cleaning PCBs, masks, imagers (e.g., CCD or CMOS sensors), and exposure optics, as well as for before and after bonding.

Dry cleaning process – efficient and gentle on resources

In contrast to wet chemical cleaning, which is still frequently used and requires not only water or solvents but also energy-intensive drying, the quattroClean technology is a dry process. The cleaning medium is liquid carbon dioxide which has been recycled and treated from chemical production processes and energy generation from biomass. The carbon dioxide is guided through a freely-adjustable, wear-free, two-substance ring nozzle and expands on exiting to form fine snow crystals. These are bundled by a separate jacket jet of compressed air and accelerated to supersonic speed. When the easily-focused jet of snow and compressed air impacts on the surface to be cleaned, a combination of thermal, mechanical, solvent and sublimation effects occur, forming the basis of the cleaning action. The crystalline carbon dioxide sublimates entirely during the process, leaving the treated surfaces completely dry. The detached contaminants are then extracted together with the process gas, thus preventing re-contamination of the parts or contamination of the surroundings.

To underpin its contribution to sustainability, the quattroClean process in combination with process gas from Linde has been GreenScreen Certified®. The certification confirms that the process medium used in cleaning processes, especially in the electronics industry, does not contain any chemical substances which are harmful to humans or the environment.

Adaptable to clean environments

acp systems tailors the cleaning solution optimally to the respective task, company-specific requirements, and production situation. To this end, the company designs systems based on standardized modules or plans them individually. For use in clean manufacturing environments, the cleaning systems, which are made entirely of stainless steel, are designed and equipped to comply with the respective cleanroom class specifications. This ensures a cleanliness of 99.995 percent for the treated liquid carbon dioxide and a quality of 1.2.1. according to ISO 8573-1:2010 for the compressed air. In order to meet semiconductor manufacturing requirements, for example, a gas scrubber that filters out traces of organic substances can also be integrated into the ultra-pure media supply for compressed air (XCDA).

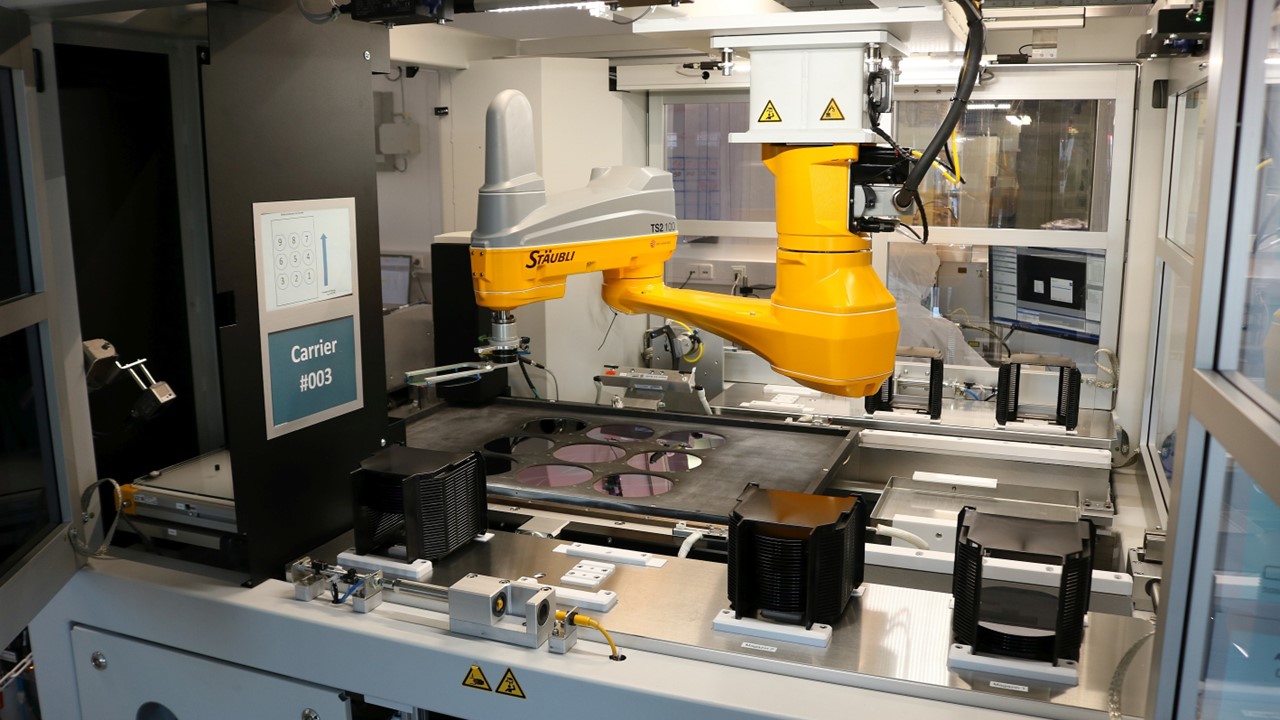

Space-saving with needs-based automation

A further advantage of the quattroClean technology is its compact size and ability to be automated as required using robot handling or linear systems, which also allow very short cycle times. On request, the equipment manufacturer takes on the customer-specific planning, documentation, and commissioning of the automation solution for the cleaning system, as well as its integration into existing production lines – even for so-called flexible materials such as flexible printed circuit boards. Machine vision-based solutions enable accurate automatic positioning and calibration of parts in production lines, as well as precise process monitoring and documentation.

Process design in cleanroom technical center

acp systems designs processes in its very own technical center, which has an ISO 7 Class cleanroom with zones up to Class 5 according to ISO 14644-1. Under these realistic production conditions, process parameters such as volume flows for compressed air and carbon dioxide, the number of nozzles, the area to be cleaned and the duration of the jet, are adapted to the respective application, while also taking material properties, the type of contamination and required level of cleanliness into account.

The dry quattroClean snow jet technology is an answer to the challenges posed by various cleaning tasks in electronics manufacturing. The process ensures the necessary cleanliness of electronic, mechanical, optical and sensor components in a robust, energy- and resource-saving manner. Furthermore, it meets the demand for end-to-end automated manufacturing processes.