Junkosha have chosen SEMICON Europa 2025, Booth C1452, to showcase its latest cleanest cable assemblies including the Super Low Outgassing Cable, narrow pitch EPTFE Flat Cable and self-supporting Flat and High-Flex Cable – each developed to maintain an ultra-clean environment within semiconductor manufacturing systems. The semiconductor manufacturing industry is undergoing rapid innovation driven by transistors at the atomic scale, accelerated time-to-market demands and the need to ensure long-term product reliability. Junkosha offers a range of advanced cable solutions specifically engineered to enhance cable performance, flexibility and contamination resistance, while improving overall cost-efficiency for both vacuum and non-vacuum applications.

“One of the most significant trends in the cleanroom cable market is the continuous improvement in cable materials,” explains Kazunao Miura, Sales Manager at Junkosha. “Manufacturers are increasingly turning to low outgassing materials for cleanroom cables to minimize the release of volatile organic compounds (VOCs) into the environment. These materials are critical in maintaining the integrity of cleanroom environments, where even the smallest contamination can compromise production quality.”

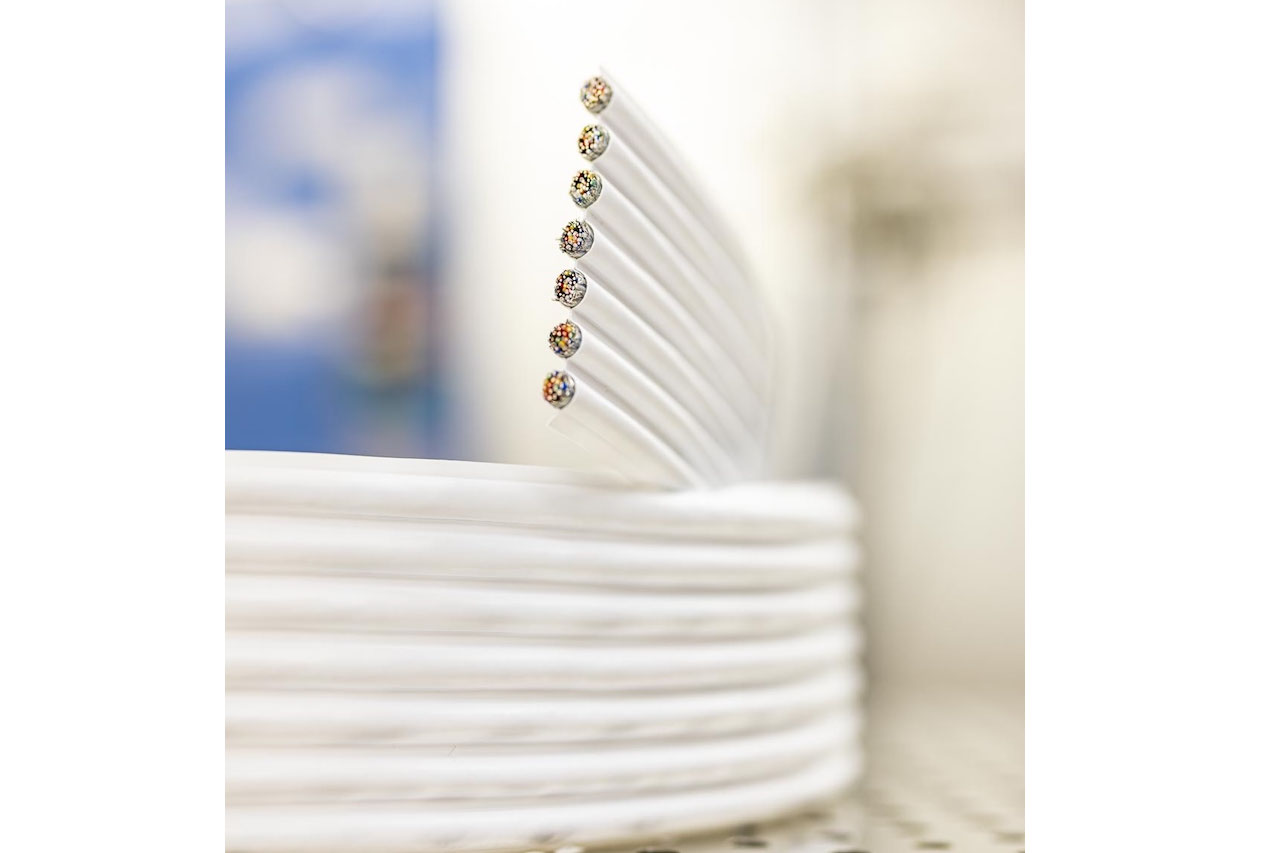

In response to this challenge, Junkosha has developed the cleanest cable assemblies in the semiconductor manufacturing industry to date. Through proprietary manufacturing processes, Junkosha® Super Low Outgassing Cables achieve the lowest outgassing and particulation levels available on the market, enabling semiconductor manufacturers to maintain an extremely clean environment within their systems. This innovation allows semiconductor manufacturers to preserve system purity while benefiting from high mechanical flexibility and the ability to integrate multiple cables, ideal for vacuum chamber environments with moving parts such as linear stages integrated with motors and encoders.

As semiconductor defect detection grows more complex and cleanroom spaces become increasingly limited, there is a growing demand for compact, high-performance cables. Junkosha narrow pitch EPTFE Flat Cable addresses this need by allowing multiple cables to be stacked without the use of dividers and shelves, reducing the overall size of the cable system. Unlike traditional flat cables, this design offers flexibility and adaptability by allowingmanufacturers to tailor pitch to specific requirements. The result is improved space utilization, durability, functionality and overall system efficiency – a key advantage as device features continue to shrink to 2nm and below.

In parallel, the self-supporting Flat and High-Flex Cable eliminates the need for cable guides,thereby minimizing particle generation, reducing weight and improving precision positioning accuracy in linear stage systems. Leveraging a patented narrow-pitch and minimized webbing design, it supports more cable cores per layer while maintaining stable motion, high durability, and support for strokes up to 1.5 meters. Designed for use in the atmospheric pressure stage, these cables deliver design flexibility for defect review and planarization processes carried out in non-vacuum environments.

“Flexible cleanroom cables are essential for handling continuous movement and bending while preventing degradation, especially in machinery that undergoes frequent motion,” continues, Miura. “Through consistent manufacturing practices and stringent quality control, Junkosha provides one of the most reliable ranges of clean, high-flex and low particulation cable products available today.”

Junkosha will be exhibiting its range of semiconductor solutions at the SEMICON Europa exhibition, Booth C1452, from November 18-21 at Messe München in Munich.

About Junkosha

Junkosha is a pioneer of sophisticated fluoropolymer application technologies across various sectors including semiconductor manufacturing, microwave interconnect and medical devices. With three operations in Japan, including its headquarters as well as sites in the US, UK and China, it is one of the best kept advanced technology secrets outside of Japan. The company provides a wide range of wire and cable products, including microwave interconnects, robot cables, high data rate cables, camera link cable assemblies, ultrafine coaxial cables and assemblies, cables for clean environments, and general wires and cables. Junkosha also offerstube and fitting products, including generic resin tubes, fluoropolymer tubes, high-barrier tubes, flexible multi-layered tubes, industrial hoses, degassing modules, heat-shrinkable tubes, and the market leading peelable heat shrink tubes.