Fluxes classified as ROL0 fluxes contain colophonium as a resin component. The new flux series EO-B-026 A – C are ROL0 fluxes of the latest generation. The fluxes are high-performance NO-CLEAN fluxes based on alcohol with a di-carboxylic acid activator complex and colophonium. These fluxes have been developed for the selective and wave soldering process, as well as for dip soldering and wire tinning.

“We are seeing an increased demand for ROL0 fluxes, particularly from Eastern Europe and North Africa. For this reason, we have decided to expand our portfolio in this regard and meet the increased demand,” explains Markus Geßner, Head of Marketing and Sales at Emil Otto GmbH, the expansion of the portfolio. The new flux is available with different solid contents: EO-B-026 (5%) and the variants A (2%), B (3%) and C (4%). All versions are characterized by a wide range of applications and very good soldering properties, particularly in terms of penetration and wetting. Despite the higher solids content, the flux is virtually residue-free. The process window shows very high thermal stability and very good activity over a very large interval, especially with OSP and ENIG soldering surfaces. The use of colophonium brings further positive properties.

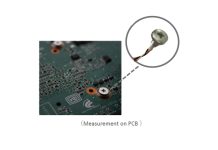

Colophonium promotes an even spread of the solder and improves the connection between the component and the PCB. Colophonium also prevents oxidation of the solder joints during the soldering process, resulting in reliable and stable connections. Compared to more activated fluxes, colophonium minimizes the risk of corrosion at the solder joints. After soldering, it leaves hardly any conductive residue, which reduces the risk of leakage currents or short circuits. Furthermore, colophonium remains effective even at higher temperatures and thus enables stable process control. These properties make colophonium-based ROL0 fluxes particularly suitable for sensitive electronic assemblies.

All flux variants can be purchased ready-to-use, as a concentrate or as a flux gel. “Flux gels are often used for repair work on assembled PCBs. In the past, fluxes for manual and repair soldering often had to be used. These contained other activators that were used for series production. The new flux gels we have developed are based on standardized activators that are contained in the existing electronic fluxes, such as the new EO-B-026. This makes us the only manufacturer to offer products on an activator basis, from the flux concentrate to the finished flux to the flux gel,” explains Geßner. Uniform activators avoid cross-reactions that can occur when using different activators from different manufacturers.

More information: www.emilotto.com.