The integration of large-area power modules with an area of over 100 mm² is highly relevant. These modules are of great importance for various applications in e-mobility, as they offer high power density and efficiency. However, connecting these components is challenging. Tresky GmbH from Berlin is presenting dispensing for Large Area Sintering at PCIM Europe 2024 to address this challenge.

“Bonding of components, AMB substrates, or PCBs used with heat sinks using silver sintering poses a high technical challenge. Factors such as warpage, surface quality, and the application and processing of pastes become increasingly complex,” explains Daniel Schultze, Managing Director of Tresky GmbH. In particular, problems arise during the dry sintering process for large power semiconductor modules, such as the difficult printability of large areas with the paste printer, the formation of depressions, also known as cavities, and warping on the AMB substrates or modules themselves. Air pockets (voids) can form between the substrate and power module, affecting the connection and potentially leading to microcracks.

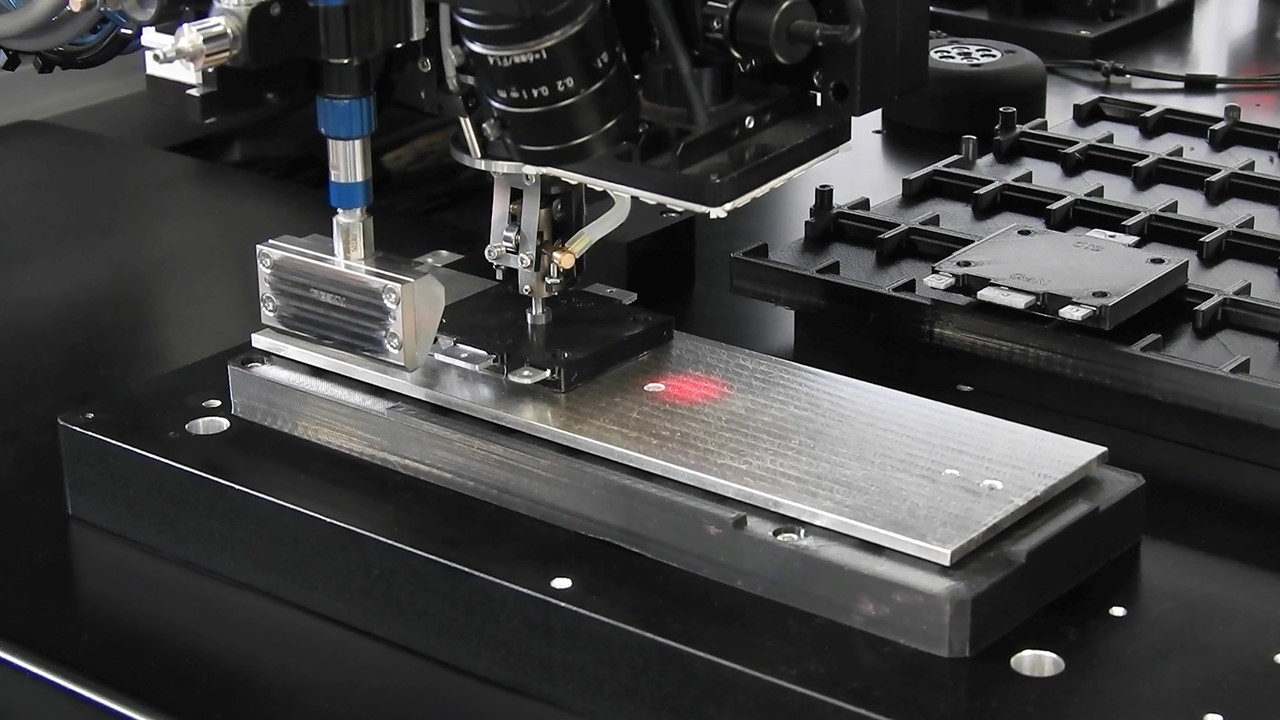

“The wet sintering process is a promising alternative here,” Schultze continues. In this process, the wet sinter paste is applied to the substrate on a large scale using a dispensing method, and the module or semiconductor is then placed directly into the paste. This method allows for compensating for the warpage of components such as the substrate and semiconductor chip through the wet sinter paste. Minimal layer thicknesses can be achieved through the dispensing process. Large Area Sintering can reduce material consumption and production costs.

The development and optimization of these specific sintering processes are crucial for producing reliable and efficient large-area power semiconductor modules. Improving connection techniques and reducing defects also increases the modules’ lifespan, leading to higher performance and operational safety, for example, in electric vehicles.

Continuous research and innovation in this area are essential to meet the industry’s increasing demands and drive technological development forward. Advanced sintering processes significantly contribute to competitiveness and sustainability, especially in e-mobility and power electronics, where efficiency and reliability are crucial.

Tresky will be presenting Large Area Sintering at PCIM Europe in Nuremberg from June 11 – 13 in Hall 5, Stand 402.

About Tresky

Since 1980 the name TRESKY stands for the highest quality, unmatched flexibility with maximum reliability.

Tresky GmbH is one of the world’s leading machine manufacturers for placement systems in the high-precision sector offering more than 40 years of experience in the semiconductor industry. The company is headquartered in Hennigsdorf near Berlin, in the middle of a technology park that is home to numerous highly specialized companies from the automation, electrical engineering, communications technology and life science sectors. Quality “Made in Germany” – Tresky develops, produces and sells Die Bonders from its headquarters in Hennigsdorf. More information: www.tresky.de.