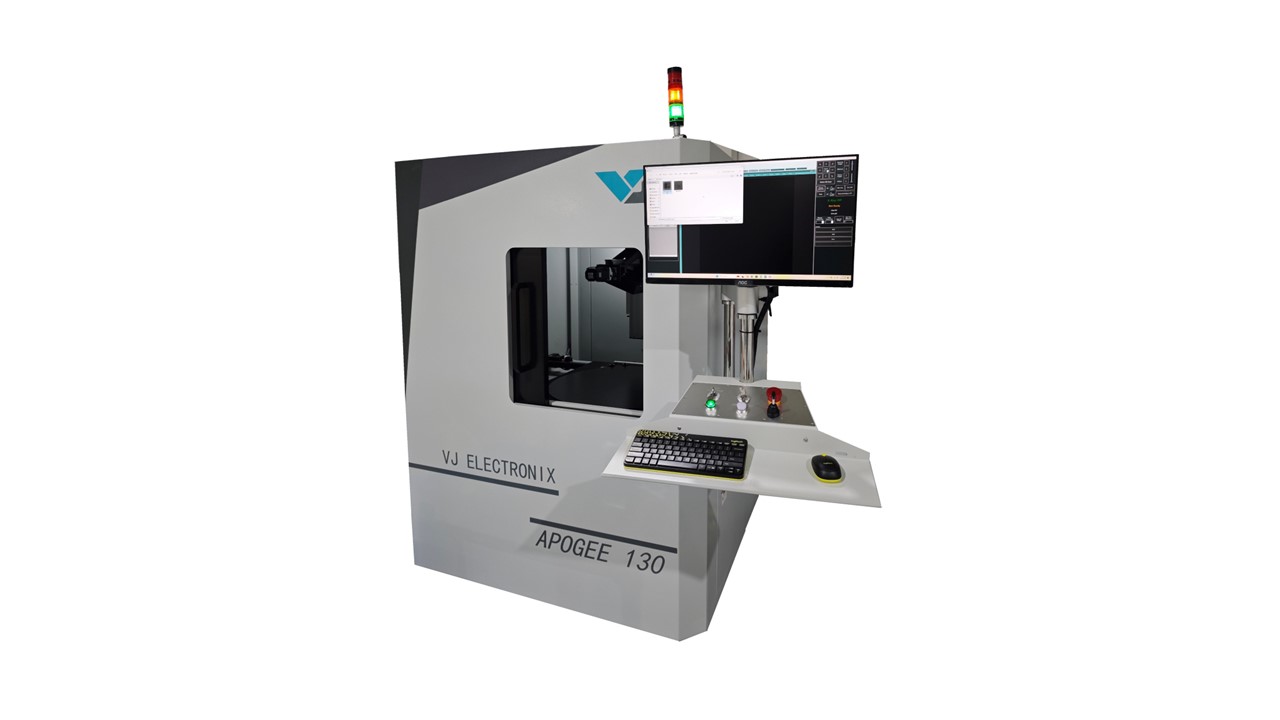

VJ Electronix, Inc., the leader in rework technologies and global provider of advanced X-ray inspection and component counting systems, is proud to unveil its latest addition to the lineup: the APOGEE 130. The new APOGEE 130 offers superior resolution, manual and automated operation, and ease of use typically found in higher-cost systems, all at an affordable price point.

High Image Quality

The APOGEE 130 is capable of capturing the highest clarity 2D & 2.5D X-ray images for a wide range of applications, including PCBs, electrical components, medical devices, counterfeit component screening and wire harness inspection. Its superior image quality ensures operators can confidently identify defects and anomalies with precision and accuracy.

Powerful Software

Equipped with Vi3 software, the APOGEE 130 makes defect detection easy with real-time image visualization, auto contrast, filters and automated tools for BGA, QFN, PTH and solder void detection. Additionally, the optional advanced Automated Defect Enhancement feature improves efficiency and accuracy in inspection tasks.

Simple Design

The APOGEE 130 boasts an intuitive GUI for navigation and control, minimizing operator training needs. With simple on-screen icons, operators can perform measurement tasks with ease, ensuring smooth and efficient operation. The system features maintenance-free X-ray components with a long service life, providing high reliability and peace of mind.

Affordable and Reliable

Designed with the superior resolution and automation typically found in higher-cost systems, the APOGEE 130 offers affordable and reliable x-ray inspection with advanced features for defect detection, failure analysis, and non-destructive testing (NDT) in production environments. Its versatility and ease of use make it an ideal solution for a wide range of inspection tasks.

“With the APOGEE 130, we aimed to provide a cost-effective X-ray inspection solution without compromising on performance or reliability,” said Don Naugler, General Manager at VJ Electronix. “We believe this system will empower operators to conduct thorough and efficient inspections, ultimately enhancing productivity and quality in production environments.”

The APOGEE 130 features a standard 39 W, 130 kV maintenance-free X-ray source, enabling inspection of larger and heavier PCBs. Its large front sliding sample door and compact footprint (47 x 56 inches) make loading easy and saves valuable floor space.

For more information about the APOGEE 130 and other solutions from VJ Electronix, visit www.vjelectronix.com.