Mek is excited to announce its presence at IPC APEX EXPO, North America’s largest electronics manufacturing event, in Anaheim, California, from April 6-11, 2024. Attendees are invited to visit Mek at booth #1433 to explore the latest AOI technology offerings. Witness firsthand how Mek AOI systems are helping to shape the future of electronics inspection technology.

Mek will be showcasing their cutting-edge 3D AOI, ISO-Spector. As Mek’s flagship full 3D Automatic Optical Inspection system, the ISO-Spector M2 boasts unparalleled hardware specifications and incorporates Artificial Intelligence to revolutionize the inspection process. Its exceptionally convenient fast automatic programming method ensures swift integration into production lines, delivering inspection results with remarkably short cycle times. What sets the ISO-Spector M2 apart is its programmer-independent programming, facilitated by AI technology. This ensures consistent inspection results regardless of the programmer’s expertise. ISO-Spector M2 will be available for demonstration via an offline station.

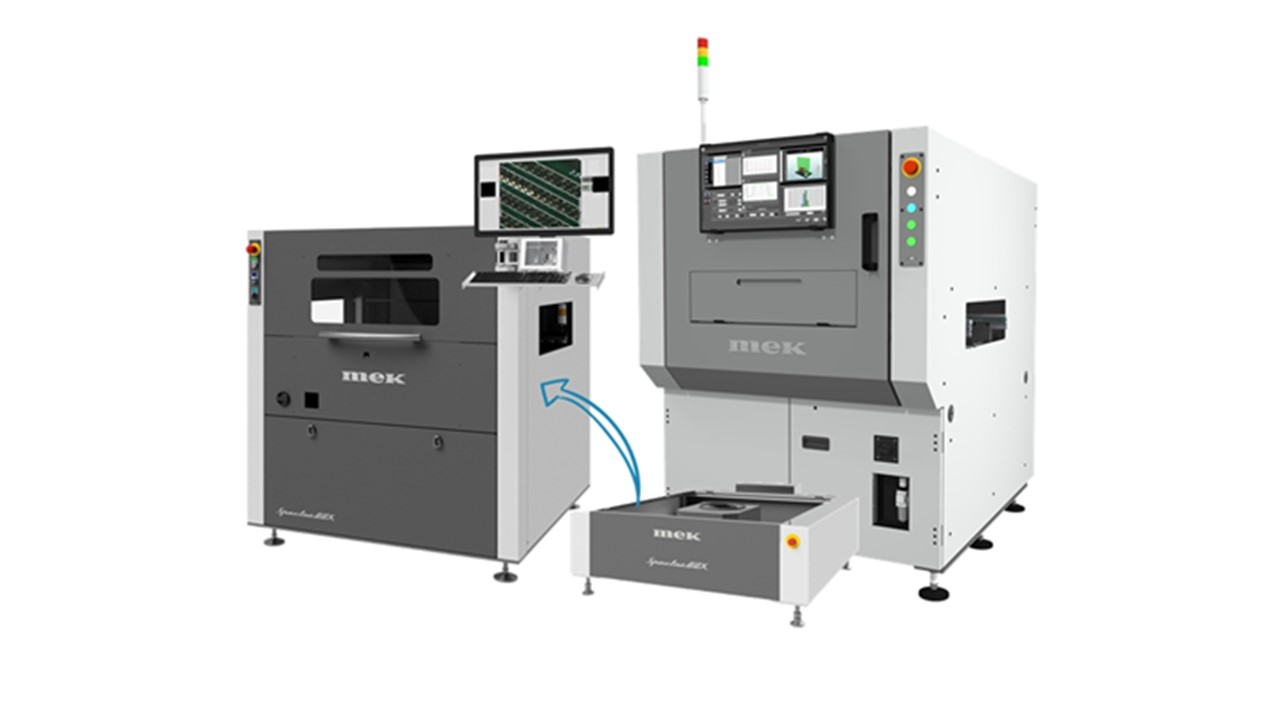

For those involved in through hole assembly, the event will be the Americas premier of the SpectorBOX X series, a modular full 3D AOI system for THT solder joints and THT components. SpectorBOX X1 redefines Through-Hole Technology (THT) inspection and can be used bottom-up for volume measurement of THT solder joints and pin height measurement, or Top-Down for a groundbreaking 150mm + clearance for 3D THT components measurement – making it the first compact 3D AOI system truly capable of inspecting THT solder joints and components with precision.

Mek will also be exhibiting the VeriSpector THT assembly station AOI, a low-cost assembly station AOI for use on manual and semi-automated SMD and THT assembly lines. Featuring an overhead orthogonal camera and LED lighting system the VeriSpector is designed for a wide verity of inspection needs.

Initially, available as a manual inspection system, VeriSpector is now available as both an in-line system and as a modular system for self-integration. These new developments allow manufacturers to easily integrate the VeriSpector Assembly Station AOI into their existing production lines, giving them even more control and flexibility in their inspection processes.

Mek EZPro Software on the ISO-Spector 3D AOI system and the full range of Through-Hole Technology (THT) AOI systems, allows for the preparation of approximately 70% of an AOI program in typically 20 minutes using only CAD + Gerber data, eliminating the need for a PCB. Additionally, with ODB++ integration, the software achieves even faster programming times, taking a maximum of approximately 10 minutes. versatility and compatibility across multiple inspection platforms.

Also at the show, visitors can experience the powerful PowerSpector benchtop AOI equipped with 9 cameras: 1 top and 8 side cameras. New, Selective 3D Laser Measurement Technology allows users to conduct selective height measurements of any object with unprecedented precision. The systems are suitable for use in pre-reflow, post-reflow, post-wave and post-selective soldering, and can also be used for 2D solder paste inspection and first article inspection.

For manufacturers for whom value for money is an absolute priority the Mek entry level iSpector JDz desktop AOI system is designed to inspect component bodies and solder joints by use of LED light sources from three different angles offering full inspection coverage at an entry level price. Powerful algorithms achieve an optimal balance between defect detection and false reject levels in the shortest time.

For more information on Mek and the entire range of products visit www.marantz-electronics.com, or visit Apex booth 1433 where the Marantz AOI experts will be available to discuss your application requirements.