KemLab Inc., a pioneering developer of advanced materials for microelectronics and MEMS applications, is pleased to offer a high-quality solution tailored to address the requirements of high-resolution direct write e-Beam lithography. HARP™ PMMA and Copolymer e-Beam Resists epitomize excellence through rigorous testing, stringent quality control measures, premium raw materials, consistent lot-to-lot performance, optimized supply chain management, and world-class technical support.

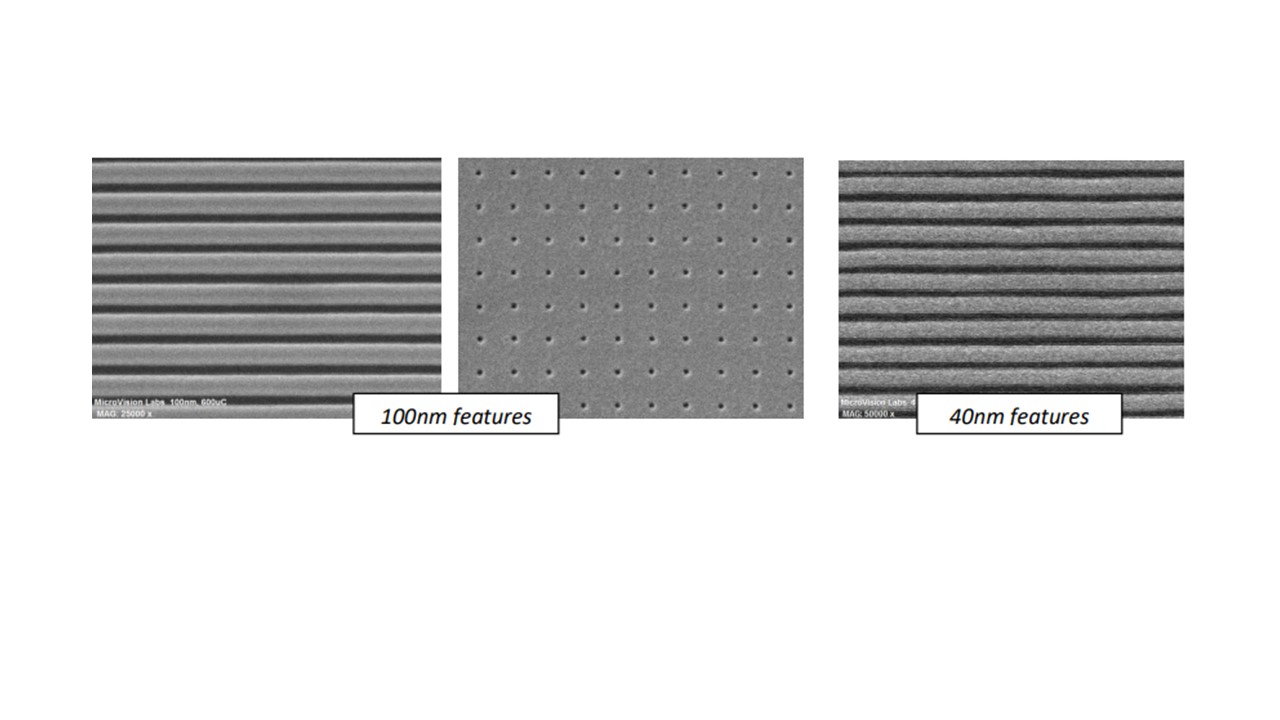

HARP™ PMMA (polymethyl methacrylate) e-Beam resist is specifically formulated for high-resolution direct write e-Beam lithography applications. When combined with HARP-C™ copolymer, the HARP multi-layer system becomes ideal for T-gate manufacture, offering unmatched precision and reliability. HARP™ PMMA exhibits excellent adhesion to a variety of substrates and can be used as a protective coating layer for wafer thinning and sacrificial layers.

The HARP™ PMMA and Copolymer e-Beam Resists offer a wide range of applications, including:

- e-Beam direct write lithography

- Multi-layer T-gate manufacture

- Protective coating for wafer thinning

“We are committed to providing our customers with safe, high-quality materials that meet their specific needs,” stated Jeremy Golden, General Manager at KemLab. “With our range of resist sizes and customization options, we can tailor our products to suit a variety of applications and volume requirements.”

Key features of HARP™ PMMA and Copolymer e-Beam Resists:

- Available in resist sizes of 100ml, 500ml, 1L, and 4L

- Developer sizes available in 4L

- Custom dilutions available upon request

For inquiries and more information, visit www.kemlab.com or get in touch with KemLab’s expert team today.