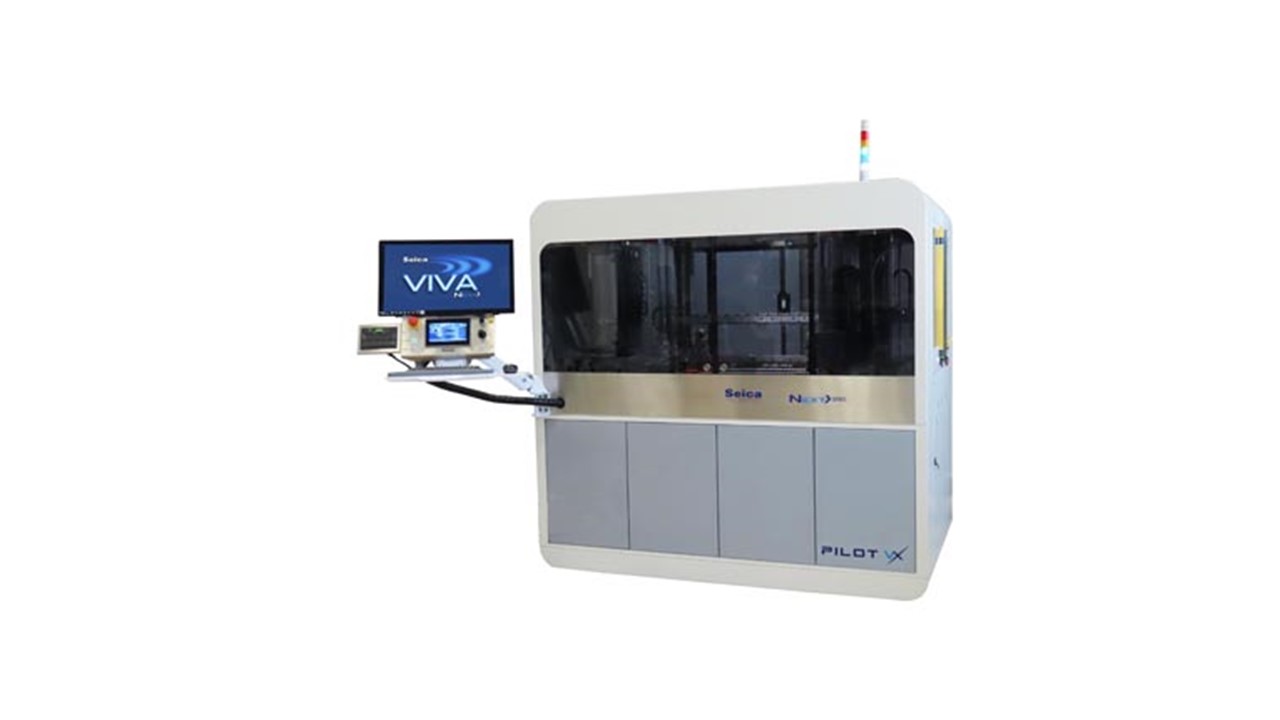

Seica unveils the latest video showcasing the capabilities of the PILOT VX, setting the gold standard for flying probe speed and performance. With cutting-edge technology and precision engineering, the PILOT VX redefines the benchmarks of efficiency and accuracy in the realm of flying probe testing. This innovative system delivers unmatched speed and reliability, ensuring rapid and thorough testing of electronic components.

More about Pilot VX

The PILOT VX test platform, is the new gold standard in terms of flying probe speed and performance. New, state-of-the-art mechanical architecture and motion controllers enable a reduction of up to 50% in test time, 12 multi-function test heads provide the capability for double-side probing of up to 44 points simultaneously and technologically advanced measurement hardware and a new microwave-based measurement technique provide unrivaled test performance. Optimized VIVA software management saves even more time by enabling the parallelization of different types of tests, and smart analysis capabilities together, with algorithms based on the principles of artificial intelligence can automatically optimize the test flow in run-time, while maintaining test coverage targets. The FlyPod option extends testing capability even more by specializing a single mobile probe to carry up to 14 channels, enabling access to boundary scan circuits and adding onboard programming capability without any external fixed cables and the Pilot VX platform includes options for testing flex circuits and the electrical and optical test of LEDs. In addition, the Pilot VX can also generate pressure/force topology maps of the device under test using the innovative FlyStrain™ option. Once a necessity for traditional fixture-based solutions, Seica has migrated these new tools to the flying prober where testing of ceramics, wafers and avionics and satellite boards requires delicate probing and traceability.

About Seica S.p.A.

Founded in 1986, Seica S.p.A. is an innovative, high technology company that develops and manufactures leading-edge solutions for the test and selective soldering of electronic boards and modules. Moreover, Seica provides battery test solutions, automotive electronic board test solutions, infotainment test, as well as electric vehicle inverter and battery charging station test systems. Seica has fully embraced the concept of Industry 4.0, developing solutions to monitor and collect information from machines and industrial plants to enable the optimization of manufacturing processes, maintenance and energy management.

Company headquarters are located in Italy, with direct offices in Germany, France, China, the USA, Mexico and Israel.