SHENMAO Technology is pleased to announce the availability of its latest innovation, the SMF-D61 Low Residue No-Clean Flip Chip Flux. This advanced flux is meticulously engineered to meet the demanding requirements of flip chip dipping applications, offering exceptional performance and reliability throughout the soldering process.

Key Features of SMF-D61:

- Low flux residue: SMF-D61 leaves behind minimal residue after reflow, ensuring clean and reliable solder joints.

- Halogen-free: Compliant with RoHS, RoHS 2.0, and REACH standards, SMF-D61 is free from intentionally added halogens, contributing to environmental sustainability.

- Designed for flip chip dipping applications: The formulation of SMF-D61 is specifically tailored to meet the unique challenges of flip chip soldering, providing optimal results in this application.

- Excellent solderability and wettability: SMF-D61 ensures superior wetting characteristics and solderability, facilitating precise and robust solder joints.

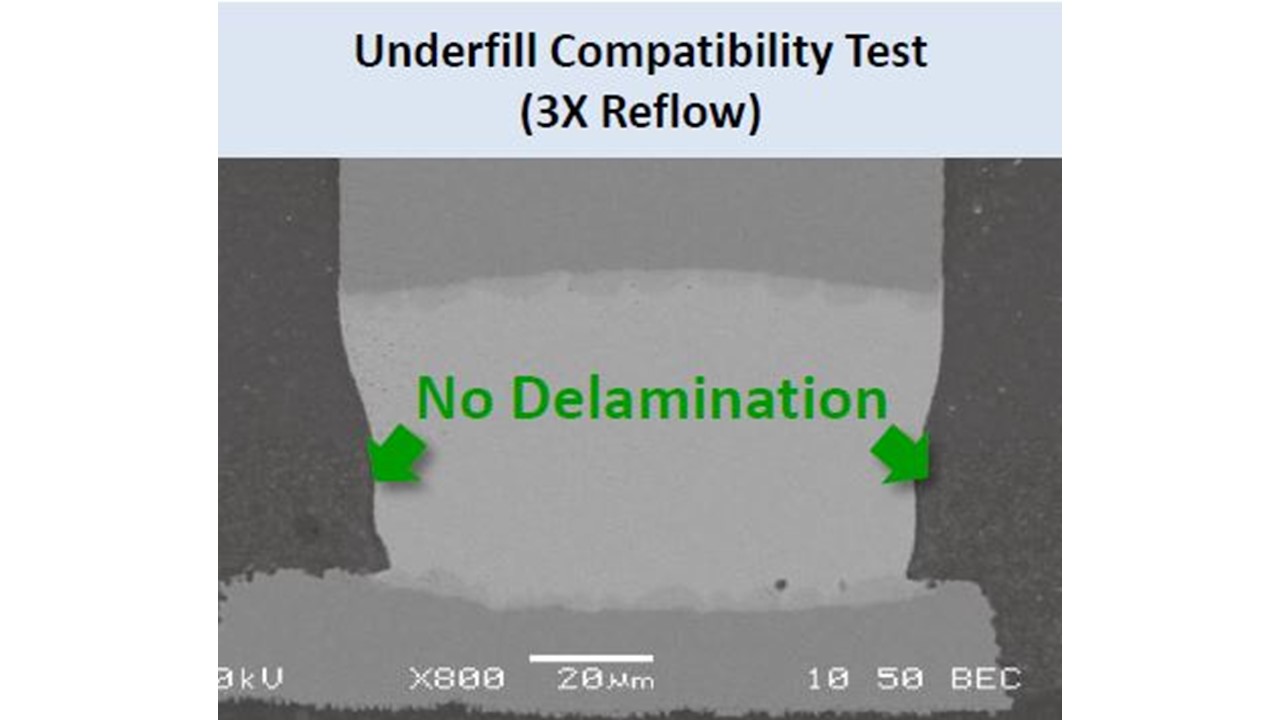

- Compatibility with underfills & Epoxy molding compound (EMC): SMF-D61 is fully compatible with underfills and EMC, eliminating the need for cleaning flux residue before proceeding with subsequent processes.

The development of SMF-D61 was driven by the need for a high-performance flux solution tailored for flip chip processes, with an emphasis on minimizing flux residue. With a special flux design, SMF-D61 achieves flux residue levels as low as 5% after reflow, ensuring optimal performance and reliability. Its compatibility with underfills and EMC further streamlines the manufacturing process by eliminating the need for post-reflow cleaning.

SMF-D61 is specifically designed for flip chip dipping applications, offering unparalleled performance and reliability in this critical process.

SHENMAO is committed to delivering cutting-edge solutions that address the evolving needs of the electronics industry. For more information about SMF-D61 and other SHENMAO products, please visit www.shenmao.com.