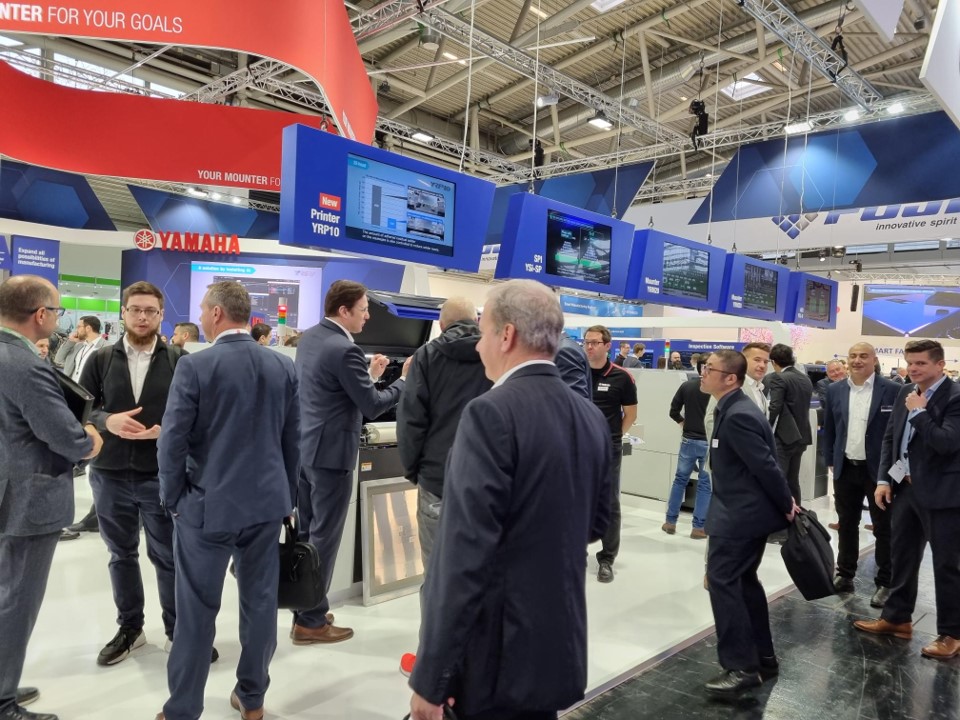

Yamaha Robotics has revealed the YRM20DL dual-lane mounter for the first time in Europe at Productronica 2023, and also introduced new features of its powerful smart-factory software tools.

Presenting the YRM20DL alongside the latest equipment in the 1 STOP SMART SOLUTION, Yamaha received the Global Technology Awards trophy for the advanced new machine in a celebration at the booth on the first evening of the event. The YRM20DL is the first dual-lane mounter that delivers complete flexibility to handle high-volume and high-mix in the same platform. It connects efficiently to Yamaha’s YRP10DL dual-lane printer and YRi-V DL dual-lane 3D AOI system.

“Productronica 2023 has been a great success, with the European debut of the YRM20DL and our exciting win in the Global Technology Awards high-volume pick-and-place category,” said Daisuke Yoshihara, General Sales Manager. “We welcomed many visitors, including new contacts and current, valued customers, keen to discover the latest innovations in our 1 STOP SMART SOLUTION and advanced, intelligent software tools.”

Yamaha’s product manager, Kamil Stasiak, introduced the new smart-factory tools at a dedicated software area on the booth, and in a special presentation at the Productronica Forum. The YSUP Dashboard, now with Automatic Analysis, instantly identifies the causes of mounter pickup errors and inspection failures to eliminate reliance on operator judgement. Additional new features analyse and verify component placement and print results.

The 1 STOP SMART SOLUTION, as displayed at Productronica, comprises Yamaha’s latest YR series surface-mount machines, bringing cutting-edge accuracy and stability and advanced features for extra speed and efficiency. The YRP10 premium printer automates laborious procedures including stencil changeover and solder-paste transfer, while the YRM20 mounter permits non-stop cart and feeder changes. The YRi-V 3D AOI system combines high-resolution vision and high-speed graphics processing, now boosted with AI to enhance component recognition, simplify programming, minimise cycle time, and increase inspection accuracy.

Productronica visitors also saw Yamaha’s industrial robots in action, demonstrating their ability to handle general assembly, picking, placing, and moving items at high speed and with high accuracy. The LCMR200 programmable workpiece transport solution works efficiently with Yamaha’s SCARA and cartesian robots to accelerate light manufacturing tasks and enhance flexibility. Real-time tracking of all LCMR200 sliders increases traceability and eases system maintenance. The special horizontal and vertical LCMR200 circulation units allow configuring 2D and 3D transport networks in space-constrained factories.

For more information and to download Yamaha’s Productronica press pack with the latest news and articles, please visit www.smt.yamaha-motor-robotics.de/press-kits.