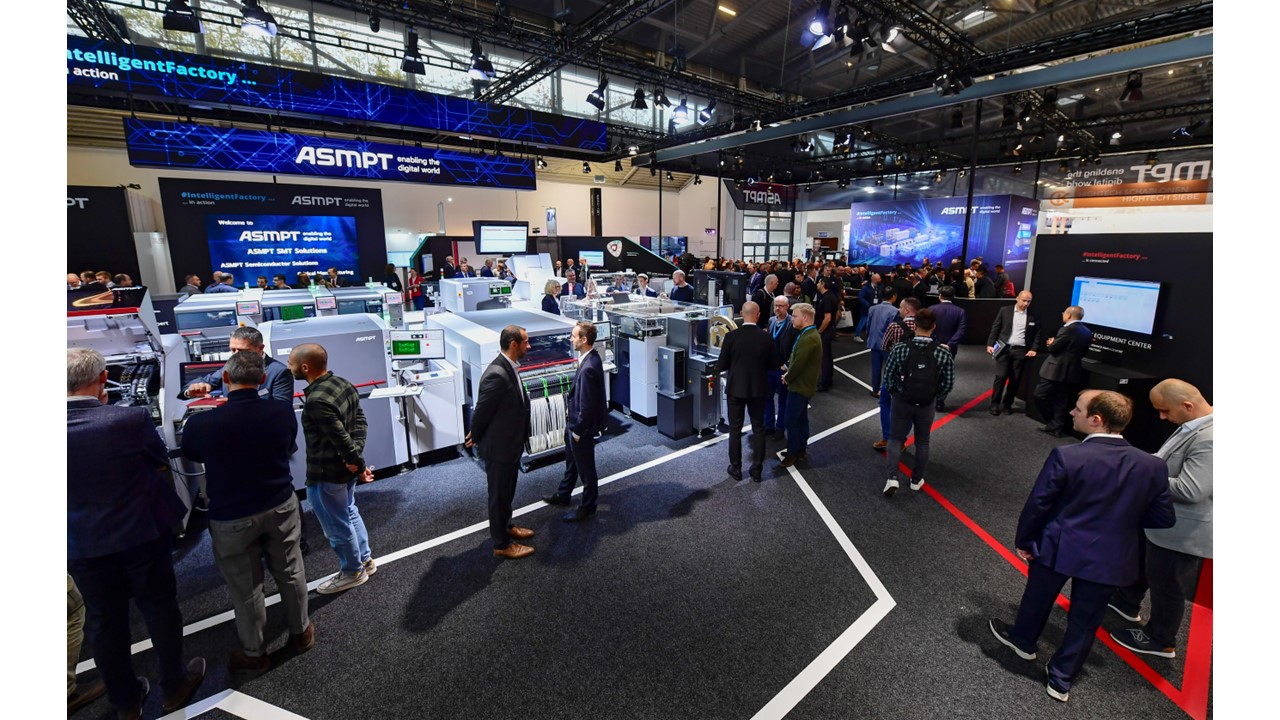

ASMPT, the global innovation and market leader in SMT and semiconductor assembly & packaging solutions, calls its extensive presence at the world’s leading trade fair productronica for electronics development and manufacturing in Munich a complete success. All its businesses – ASMPT Semiconductor Solutions, ASMPT SMT Solutions, and Critical Manufacturing – presented themselves as an innovative and integrated whole.

“What belongs together in the semiconductor industry is coming together,” said Guenter Lauber, EVP & Chief Strategy and Digitalization Officer at ASMPT. “Innovative developments such as system-in-package components, but also increasing cost pressures, require us to overcome the boundaries between SMT and die processing, and to think and act across lines, products and manufacturing facilities when it comes to data use.”

Industry visitors were able to see what this looks like in practice at the joint ASMPT booth, where ASMPT Semiconductor Solutions presented new innovative machines that are particularly interesting for automotive applications in the areas of ADAS, connectivity and electrification that require maximum precision and unique speeds. With an SMT production line that was fully optimized for volume production and a flexible SMT line for small-batch production, ASMPT demonstrated once again that the innovation and market leader is able to cover the entire hardware spectrum for modern electronics manufacturing. The hybrid pick-and-place machine SIPLACE CA marks the successful synthesis between chip assembly and SMT processing, and the industry audience’s interest was correspondingly high.

ASMPT’s software products were all about its new Intelligent Factory concept, which focuses on the smart use of data and connects all production levels from the machines to the enterprise into a functional and productive whole. As a result, skilled workers are deployed more efficiently, materials are scheduled more effectively, and errors and production impediments are detected and rectified more quickly. Also trend-setting was ASMPT’s Critical Manufacturing software business, which presented its modern, integrated manufacturing execution system (MES) designed specifically for electronics manufacturing at the trade fair.

“Frequent feedback from our customers was: “What I would otherwise have to put together from many different sources, the market leader is now offering from a single source”,” said Guenter Lauber. “This means ASMPT features a hardware and software concept that is as coherent as it is comprehensive while incorporating existing third-party solutions and combining the performance and precision of proven hardware with future-oriented software.”

“Lively interest by the public and extremely positive customer feedback at the fair are both a confirmation of our work and an incentive,” says Guenter Lauber, about his company’s endeavors. “In 2024, we will continue to consistently advance our integrative strategy in all divisions. Achieving the greatest return on investment for our customers, however, is and continues to be our overarching goal in everything we do.”

To learn more, visit www.asmpt.com.