With its inspection systems, Viscom offers electronics manufacturers worldwide comprehensive inspection coverage – from 3D SPI and 3D AOI to 3D AXI and 3D MXI. At SMTA Mexico, October 25–26, 2023 in Guadalajara, their networking will be a particular focus. Visitors to Booth #1517 can learn more about Viscom’s digital platform vConnect, which has won a GLOBAL Technology Award in the “Software Production” category.

In multiple regions in Mexico, automotive and aerospace sectors rely on Viscom’s intelligently networked systems. “We continue to grow from year to year in this important country for us. Nearshoring and trade agreements with the U.S. undoubtedly also have a major influence on this,” says Jesper Lykke, CEO of Viscom Inc., the U.S. subsidiary of Viscom AG. Vice President of Viscom Inc. Juan Briceño added: “Our team of 15 employees is exclusively responsible for customers in Mexico and that region from our office in Zapopan. We have been providing local service and support for over 15 years now.”

With “The Hermes Standard” (IPC HERMES 9852) or the IPC CFX (Connected Factory Exchange) communication standard, Viscom integrates manufacturer-independent solutions into its inspection systems. At its headquarters in Germany, Viscom furthermore develops and implements its own advanced applications related to the networking of important processes. The spectrum ranges from closed-loop functions of the SPI systems to simple merging of results from all inspection gates to multiline verification and statistically supported control of product quality.

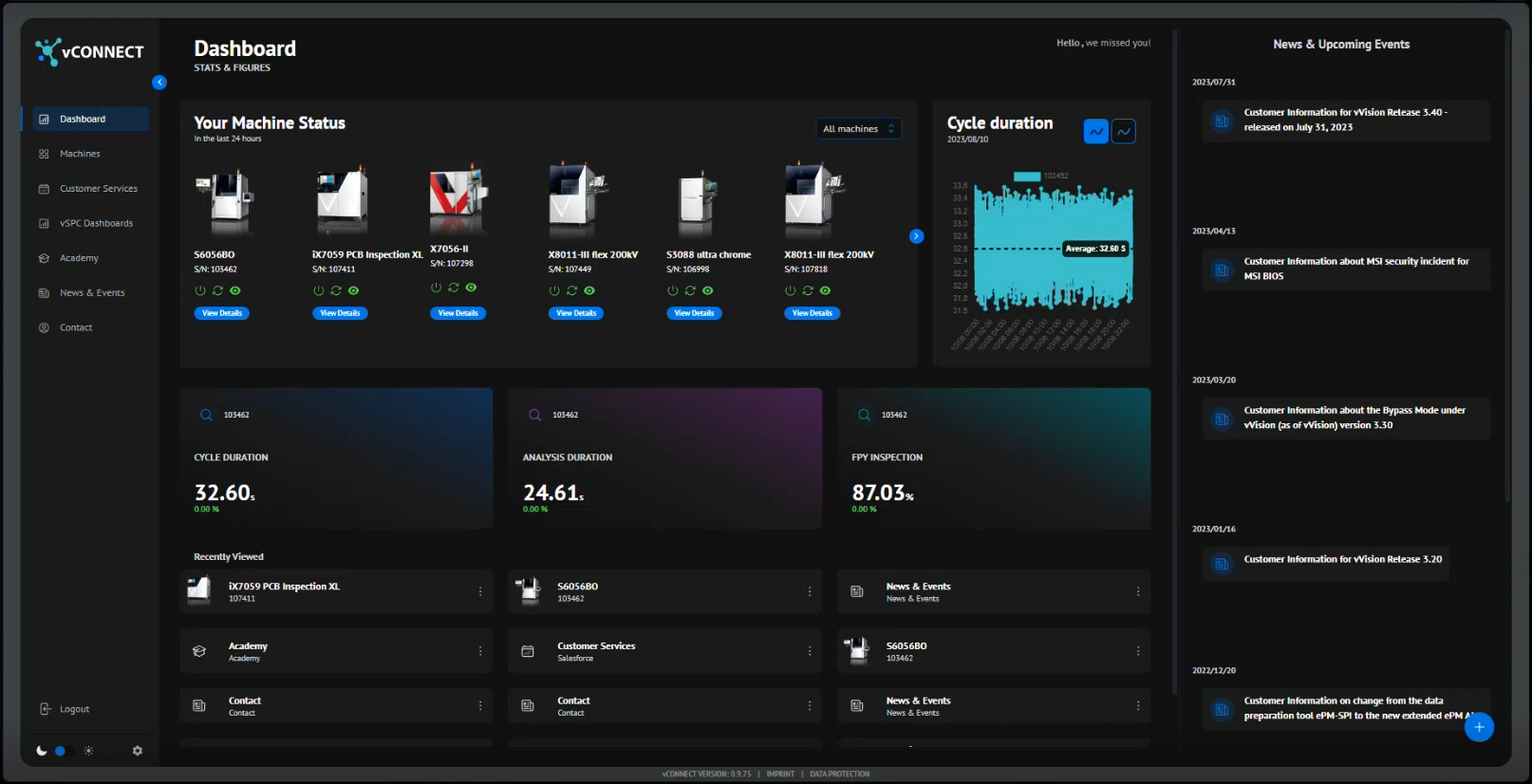

Now, Viscom’s latest solution for smart networking is set to make greater inroads in Mexico and other markets worldwide: the modular platform vConnect. It creates an optimal environment and infrastructure for comprehensively monitoring machine processes, increasing plant safety, evaluating information collected, and presenting it in graphically appealing dashboards. Extensive data is available via fully configurable menus, which can be selected according to the requirements of operators, service personnel or management.

In addition, vConnect opens the possibility for very efficient monitoring and administration of the computer infrastructure, allowing Viscom experts to quickly decipher anomalies at customers’ sites and intervene immediately if necessary. IT security and back-up services can be controlled centrally. This applies both to the inspection systems and to the classification and programming stations. Another component of the award-winning software is scalable storage solutions that can be implemented both locally and via cloud connections, enabling the targeted processing of large volumes of different data. Regarding inspection results, Viscom offers vSPC 2.0, enabling a cross-site integration of statistical process control in vConnect.

The GLOBAL Technology Award for vConnect is proudly displayed at the North American HQ of Viscom Inc. in Duluth, GA. The awards are hosted by international industry magazine Global SMT & Packaging, and since winning last year the modular platform has evolved even further.

About Viscom

Founded in 1984, Viscom AG is one of the leading suppliers worldwide in the field of assembly inspection within electronics production. With its headquarters and production site in Hanover, Germany, the company develops, produces and sells high-quality inspection systems from the areas of AOI, SPI, AXI, MXI, wire bond inspection as well as conformal coating inspection. The systems developed and manufactured in Hanover set high standards in terms of accuracy and speed. The product range covers the complete spectrum of optical inspection and X-ray inspection for small and medium-sized companies as well as for large series production. Viscom systems are used for 100% automatic inspection of electronic assemblies such as those used in the production of automotive electronics, aerospace technology or in the manufacture of telecommunications electronics.

Product development also focuses on customer-specific system developments and networking with other production processes for smart factory applications. In order to achieve this, Viscom AG increasingly invests in its own software and hardware development which is constantly defining new standards in inspection technology.

International sales are handled by a broad network of its own subsidiaries, application centers, service centers and representatives. A service team of in-house technicians and application specialists commission Viscom systems worldwide, offering maintenance, conversion and modernization from a single source. In addition, system-specific training courses are offered for customers’ operators, programmers and maintenance personnel. Experienced engineers and technicians from the application and service departments share their expert knowledge with participants.

Viscom AG has been listed on the Frankfurt Stock Exchange since 2006 (ISIN: DE0007846867).