For several years now, Motek/Bondexpo in Stuttgart has been a consistent part of Rehm Thermal Systems’ trade fair calendar. The focused orientation of the trade fair on the process chain of joining/connecting through adhesive bonding, potting, sealing, and foaming makes it an ideal platform for Rehm, especially in the areas of Conformal Coating and Dispensing. At Bondexpo, in Hall 5, Booth 5505, a ProtectoXP with an integrated 3D height sensor will be showcased, enabling reliable dispensing on various shapes.

Motek/Bondexpo provides designers, investment decision-makers, and purchasers with a clear profile, strong themes, and practical solutions, giving them everything they need to enhance and make their manufacturing processes more cost-effective. In a pleasant atmosphere, suppliers and users come together to discuss practical and actionable solutions.

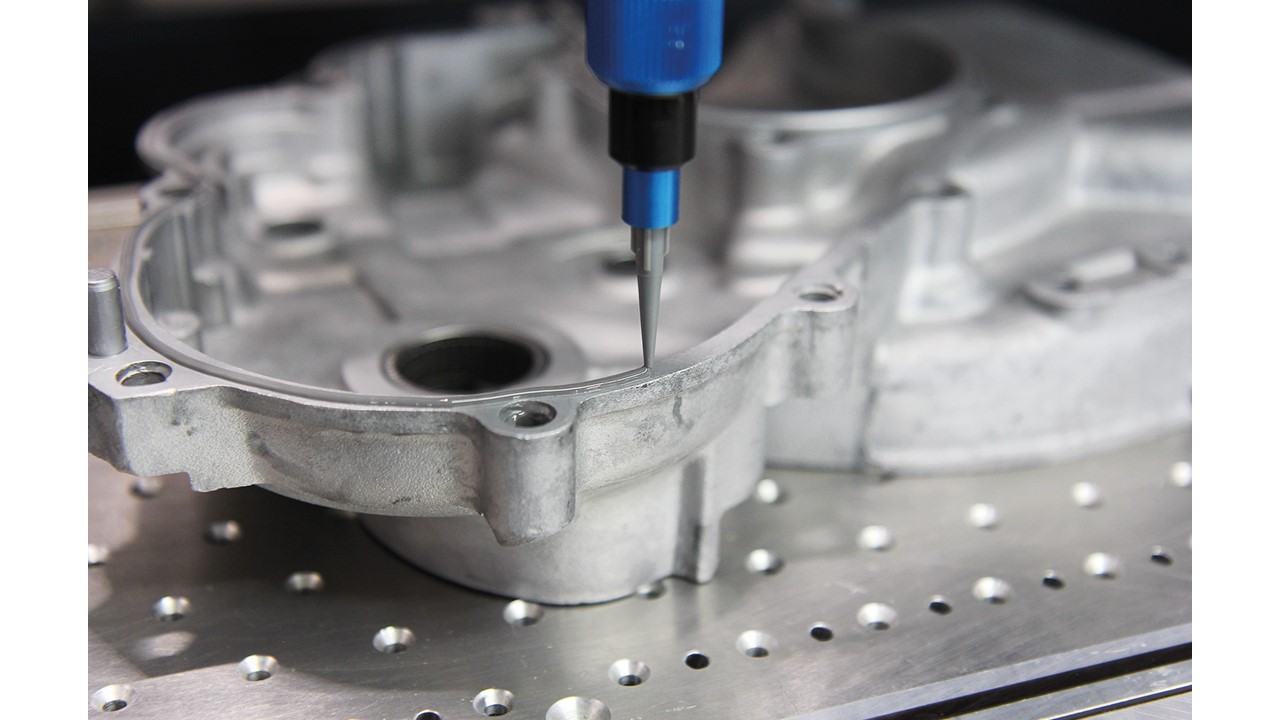

On-site Rehm experts are available to answer all questions related to dispensing various materials for joining processes, as well as potting and securing components. At Hall 5, Booth 5505, you can witness live demonstrations on a ProtectoXP, showcasing the diverse application areas and the new integrated 3D height sensor of this coating and dispensing system.

The Protecto systems deliver secure, automated processes and precise outcomes for applying a wide range of materials. They excel with robust engineering and versatile applications in the fields of dispensing and adhesive technology. With up to 4 applicators usable simultaneously, users have various options: In addition to dispensing, the ProtectoX series stands out for its ability to create freely defined three-dimensional enclosure shapes through simple application. Instant curing of UV coatings is possible with ProtectoX systems, as well as potting or bonding different materials.

The systems are operated through the intuitively controlled ViCON Protecto, which is particularly user-friendly due to its newly developed touchscreen interface. It features numerous software capabilities, including the ability to directly import eCAD data and image files for optimizing the coating process through trimming. Furthermore, coating programs can be created directly on the machine or at an offline workstation.

Gianfranco Sinistra, Product Sales at Rehm Thermal Systems, will also provide information on “Smart Solutions for Dispensing Applications” in his presentation on Wednesday, October 11, at 09:40 AM in the Motek Exhibitor Forum, Hall 5, Booth 5435. He will discuss the possibilities of designing complete dispensing lines as well as their horizontal and vertical integration for automated application control.

Attached, you will find visual material: 1.) ProtectoX series for rapid and precise coating and dispensing 2.) 3D height sensor 3.) Application of sealing material 4.) 2K potting (Images: Rehm Thermal Systems)

About Rehm Thermal Systems

Rehm Thermal Systems is a specialist in the field of thermal system solutions for the electronics and photovoltaics industry and regarded as being a technological and innovation leader in the modern and economical production of electronic assemblies. As a globally active manufacturer of reflow soldering systems with convection, condensation or vacuum, drying and coating systems, functional test systems, equipment for the metallisation of solar cells as well as numerous customer-specific special systems, we are represented in all relevant growth markets and, as a partner with more than 30 years of industry experience, we create innovative manufacturing solutions that set standards.www.rehm-group.com.

![NEPCON JAPAN [September] 2025 to Welcome 26,000 Trade Visitors and 350 Exhibitors at Makuhari Messe NEPCON JAPAN [September] 2025 to Welcome 26,000 Trade Visitors and 350 Exhibitors at Makuhari Messe](https://smttoday.com/wp-content/uploads/2025/07/PR-36-218x150.jpg)