MIRTEC, ‘The Global Leader in Inspection Technology’, is pleased to announce its participation in the upcoming SMTA Guadalajara Expo on Wednesday, Oct. 25, 2023. The event is scheduled to take place at Expo Guadalajara in Jalisco, Mexico. In Booth 319, MIRTEC will feature a total of four (4) Inspection Systems specifically designed to address the full spectrum of inspection requirements associated with the Electronics Manufacturing Industry:

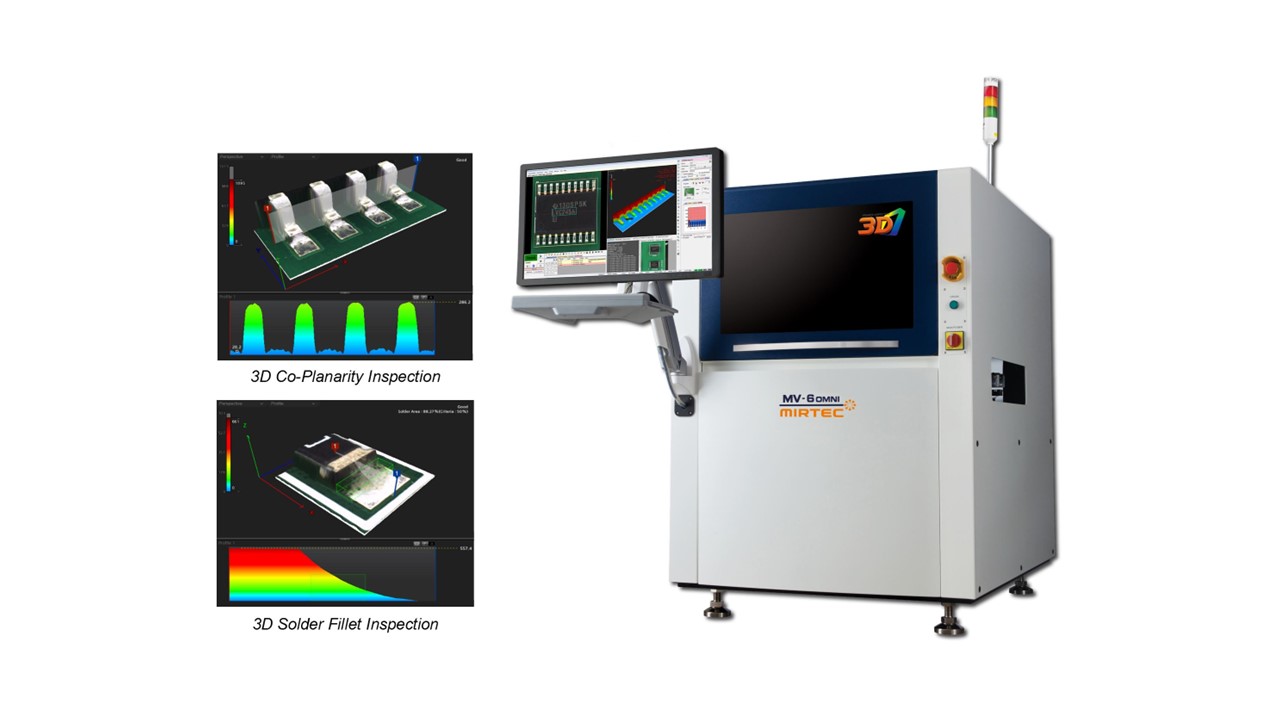

MIRTEC’s Award-Winning MV-6 OMNI 3D AOI Series feature our exclusive OMNI-VISION® 3D Inspection Technology which combines either a 15MP or 25MP CoaXPress Camera with MIRTEC’s revolutionary 12 Projection BLUE Moiré 3D Technology in a cost-effective platform. MIRTEC’s proprietary Ultra-High resolution CoaXPress Vision System is designed and manufactured by MIRTEC for use with our complete product range of 3D inspection systems. MIRTEC’s 12 Projection Digital BLUE Moiré Technology provides true 3D inspection to yield precise height measurement data used to detect lifted component and lifted lead defects as well as solder volume post reflow. Fully configured MIRTEC’s MV-6 OMNI machines feature four 10MP or 18MP Side-View Cameras in addition to the Top-Down Camera, a Multi-Focus Programmable Z-Axis System, an Internal PCB Flipper Conveyor, and Multi-Function AOI/SPI Fusion Technology.

AI Powered Smart Factory Automation Solution

MIRTEC’s Smart Factory Automation solution, ‘INTELLI-PRO’, is an AI based Software Suite specifically designed for the purpose of improving the performance and convenience of MIRTEC’s complete line of AOI machines. INTELLI-PRO consists of a proprietary Deep Learning based Automatic Part Search and Teaching function, and AI based; Automatic Parameter Optimization, Character Recognition (OCR), Foreign Object Detection (FOD), Placement Inspection Algorithms and an Automatic Defect Type Classification function.

MIRTEC’s Award-Winning MS-11e 3D SPI Series feature our exclusive 15MP or 25MP CoaXPress Camera Technology, providing enhanced image quality, superior accuracy, and incredibly fast inspection rates. The MS-11e 3D SPI is also available with a cost-effective 4MP Camera Link option. These machines uses Dual Projection Shadow Free Moiré Phase Shift Imaging Technology to inspect solder paste depositions on PCBs post screen print for insufficient/excessive solder, shape deformity, shift of deposition and bridging. All MIRTEC 3D SPI machines are CFX complaint and feature upstream and downstream Closed Loop Feedback.

MIRTEC’s Award-Winning GENESYS-PIN Hybrid 3D AOI Series is specifically developed for the Automotive Electronics Market. This extraordinary system is configured with a 12 Megapixel CoaXPress High-speed Camera System, a 15um Precision Telecentric Lens, an advanced nine (9) Phase RGB Color Lighting System, a Programmable Multi-Focus Z-Axis System, and four (4) Programmable Multi-Pattern Digital Projectors which are an integral part of MIRTEC’s proprietary Hybrid 3D Measurement Technology. With this revolutionary optical system, the GENESYS-PIN machine can measure up to 50mm tall connector pins with extreme accuracy. The GENESYS-PIN machine detects defects such as missing pins, pin offset as well as measurement of distance between pins and inner/outer dimensions of forked pins.

New to SMTA Guadalajara Expo 2023, MIRTEC will be displaying our GENESYS-CC AI Based Conformal Coating AOI Series. These revolutionary systems are configured with MIRTEC’s Exclusive 15MP CoaxPress Camera Technology, four 18MP Side-Angle Cameras and an optional Internal PCB Flipper Conveyor for Double Sided PCB Inspection. The GENESYS-CC machine inspects for Presence/Absence of Conformal Coating, AI Based Bubble Inspection and Lateral Side Component CC Inspection using the 18MP Side Cameras. The system is also fully capable of standard PCB inspection, providing maximum flexibility to the Electronics Manufacturing Environment.

MIRTEC is Leading the Way to Industry 4.0

MIRTEC’s Total Remote Management System (TRMS) is a fully integrated Industry 4.0 Solution which combines remote management with real-time data monitoring and analysis for each system within the SMT production line. MIRTEC’s TRMS provides real-time remote monitoring of status information and statistical data such as equipment operation status, production yield, PC resources, temperature, humidity, etc. The combination of MIRTEC’s 3D Inspection Systems and TRMS provide a vast improvement in production process management. The TRMS Module is a key part of MIRTEC’s Intelligent Factory Automation System, INTELLISYS®. This powerful software suite was designed and developed by MIRTEC to provide manufacturers with a clear view into the manufacturing process, thereby helping them achieve higher operating efficiencies and improved quality.

“We are excited to display our Leading-Edge Inspection Solutions at this year’s SMTA Guadalajara Expo,” said Brian D’Amico, President of MIRTEC’s North American Sales and Service Division. “Please be sure to visit with us at this year’s event to experience the future of Inspection Technology first-hand and to learn more about how MIRTEC can help your business achieve the highest levels of Quality, Efficiency and Profitability.”

To learn more, visit www.mirtecusa.com.