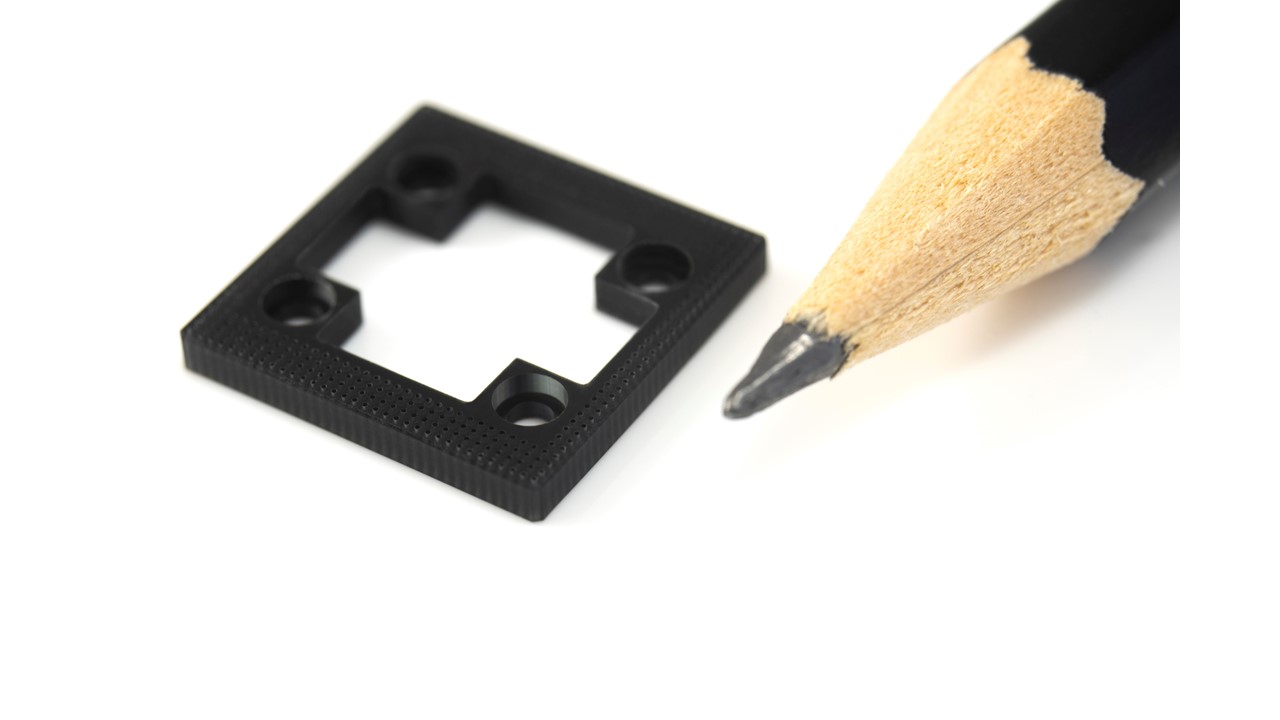

To support additional material options for its customers, Boston Micro Fabrication (BMF) has qualified Mechnano’s Formula1µ resin for use in its 10 micron S240 printers and the company’s newest 3D printer platform, the 25 micron microArch S350. BMF’s platform is ideal for printing micro-scale parts with high-resolution features, along with a broader range of small parts requiring high accuracy or precision.

Formula1µ revolutionizes static dissipative part fabrication for use in 90C and below environments by making it fast and affordable. The new qualification allows researchers and manufactures to create prototypes, manufacturing aids, and end-use parts with electrostatic dissipative (ESD) properties.

“Our team is excited to announce this qualification,” said Mechnano President Bryce Keeler. “Formula1µ provides BMF customers with a high-performance resin—delivering the highest tensile strength option available on the BMF platform and the only resin that dissipates static electricity. With the dual increase of electronics usage and decrease in chip size, the applications requiring micro-ESD parts are growing daily.”

“We’re continuing to collaborate across the industry to expand the use of 3D printing from discrete, prototyping applications into a solution that drives highly precise production of parts across industries including electronics, medical devices, and the life sciences,” said BMF CEO John Kawola. “Thanks to Mechnano’s innovation, we’re now able to offer our customers another material option to support their prototyping and longer-term production needs.”

Mechnano’s Formula1µ is a black, rigid, static-dissipative photopolymer resin that was created using the company’s proprietary discrete Carbon Nanotube technology, D’Func, to produce high resolution, Nano-Uniform ESD parts with isotropic properties and no carbon sloughing.

BMF will begin offering this material for sale in September 2023 under the name Formula1µ. Learn more about the solution here: www.mechnano.com/formula1u.