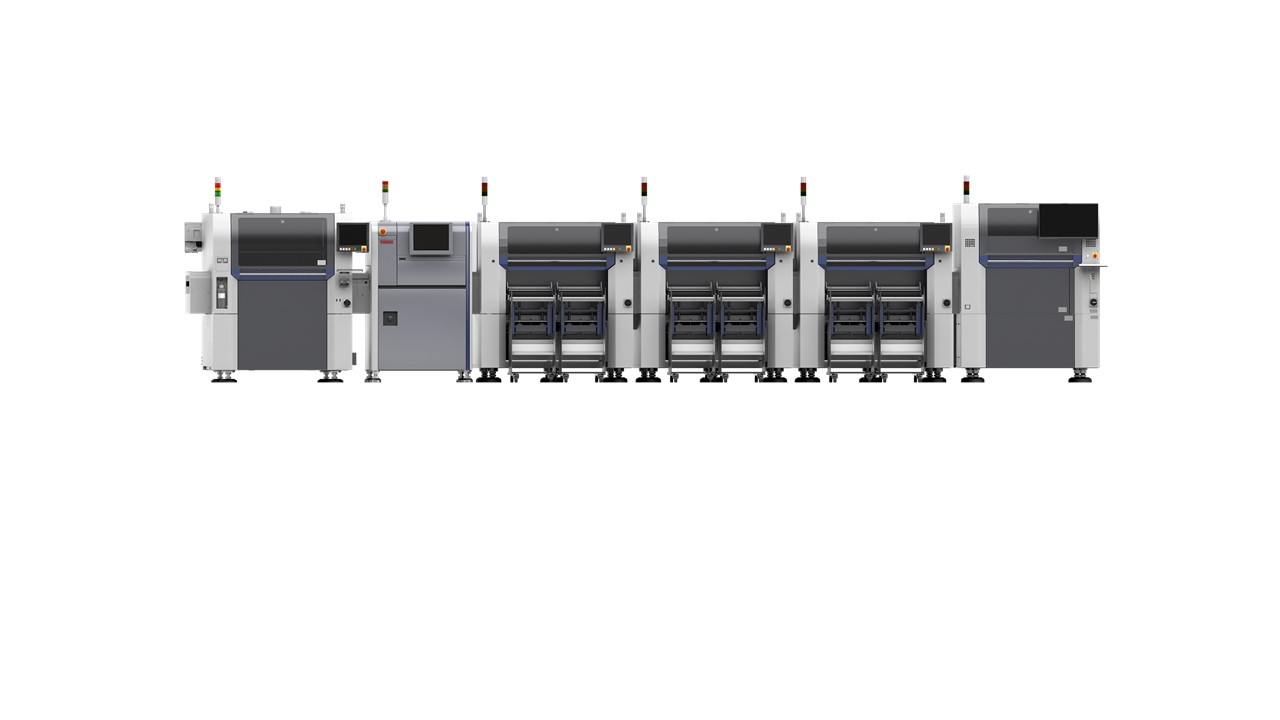

Yamaha Robotics will display the latest-generation 1 STOP SMART SOLUTION at A3.323 at Productronica 2023, bringing together the complete set of new YR series printers, surface-mounters and inspection machines. The new YRM20DL dual-lane mounter will premiere on the booth, and a full area will be dedicated to Yamaha software solutions. Additionally, a Factory Automation demonstration will present flexible robots for mechanical assembly.

The latest YR series surface-mount machines from Yamaha deliver increased accuracy and stability and enable fully automated changeovers for unprecedented speed and efficiency. In the new YRP10 premium printer, automation permits immediate stencil change for sustained high throughput and consistent solder-paste condition. The YRM20 mounter permits non-stop cart and feeder changes, combined with high placement speed and a choice of flexible heads to maximise throughput. And the YRi-V 3D AOI system with high-resolution vision, high-speed graphics processing, and AI to boost component recognition, eases programming, cuts cycle time, and raises inspection accuracy.

The YRM20DL dual-lane mounter will be on display for the first time in Europe. With equal board-size adjustment range and support for all automated features on each lane, the YRM20DL enables owners to increase throughput, flexibility, and efficiency at the same time.

An area dedicated to software will let visitors check out the latest YSUP graphical user interface (GUI) and intelligent factory tools that ensure best performance from the YR series machines. With easy-to-use menus and rich 3D graphics, the YSUP suite helps setup and monitor all equipment in the line and automatically identifies causes of inspection failures to help solve any issues and restore maximum productivity.

The Yamaha booth will also showcase industrial robots for general assembly tasks. Highlighting the flexibility of the LCMR200 workpiece transport solution, the demonstration will show how items can be moved quickly between various assembly processes. These can be performed directly on LCMR200 sliders using a SCARA or cartesian robot. Horizontal and vertical circulation units for the LCMR200 allow building 2D and 3D transport networks, giving flexibility to optimize production and individualise products while achieving a compact assembly cell size.

“The latest-generation YR surface-mount series of our 1 STOP SMART SOLUTION offers exciting opportunities for Europe’s high-tech manufacturers, with more speed, greater accuracy, and more powerful tools to optimize productivity,” said Daisuke Yoshihara, General Sales Manager. “We are also excited to show how our robots can automate miscellaneous assembly and transportation tasks to further boost production.”

As always, Yamaha Robotics’ booth will be staffed by technical experts and sales professionals, ready to highlight Yamaha Intelligent Factory and explain the details.Visit us in Hall 3, booth 323 at Productronica 2023, November 14-17 in Munich, Germany.

About Yamaha Robotics SMT Section

Yamaha Surface Mount Technology (SMT) Section, a subdivision of Yamaha Motor Robotics Business Unit in Yamaha Motor Corporation, produces a complete selection of equipment for high-speed inline electronic assembly. This 1 STOP SMART SOLUTION includes solder paste printers, component mounters, 3D solder paste inspection machines, 3D PCB inspection machines, flip-chip hybrid placers, dispensers, intelligent component storage, and management software.

Bringing the Yamaha way to electronics manufacturing, these systems prioritize intuitive operator interaction, efficient coordination between all inline processes, and modularity enabling users to meet the latest manufacturing demands. Group competencies in servo-motor control and image recognition for vision (camera) systems ensure extreme accuracy with high speed.

The current product line includes the latest YR equipment generation, with advanced automated features for programming, setup, and changeovers, and new YSUP management software with state-of-the-art graphics and built-in data analytics.

Combining design and engineering, manufacture, sales, and service competencies, Yamaha SMT Section ensures operational efficiency and easy access to support for customers and partners. With regional offices in Japan, China, Southeast Asia, Europe and North America, the company provides truly global presence.