The local Chinese teams of Viscom AG are in the starting blocks for their participation at NEPCON China 2023 in Shanghai. They will present a wide variety of inspection systems for different requirements and inspection gates. An overarching topic that will be in the spotlight at Viscom is artificial intelligence and its contribution to even more efficient quality control.

The electronics industry will come together at the Shanghai World Expo Exhibition & Convention Center from July 19 to 21, 2023, and Viscom China will be participating with booth 1J20. Experts will answer individual questions and be available for technical demonstrations. Great interest is expected in connection with the use of AI – for example, in the verification of inspection results, where decisions can gradually be made by the application itself. Other AI solutions developed at Viscom are, e.g., the X-ray based segmentation of voids and the automated creation of inspection programs. The focus is primarily to relieve the burden on employees at the assembly lines.

The inspection systems on display at the Viscom booth are a perfect example to practically illustrate the complete SMT manufacturing process. The S3088 ultra chrome SPI inspects solder pads quickly and with high precision boasting a height resolution of 0.1 µm/pixel. The system’s communication with the printer enables automatic misalignment corrections and optimization of stencil cleaning cycles. The placer, in turn, can use another closed loop to the SPI machine to base the positioning of the components on the actual solder paste alignment. After passing through the reflow oven, the high-throughput S3088 ultra chrome 3D-AOI system takes over the control of soldering and component positions. Nine cameras ensure virtually shadow-free 3D inspection.

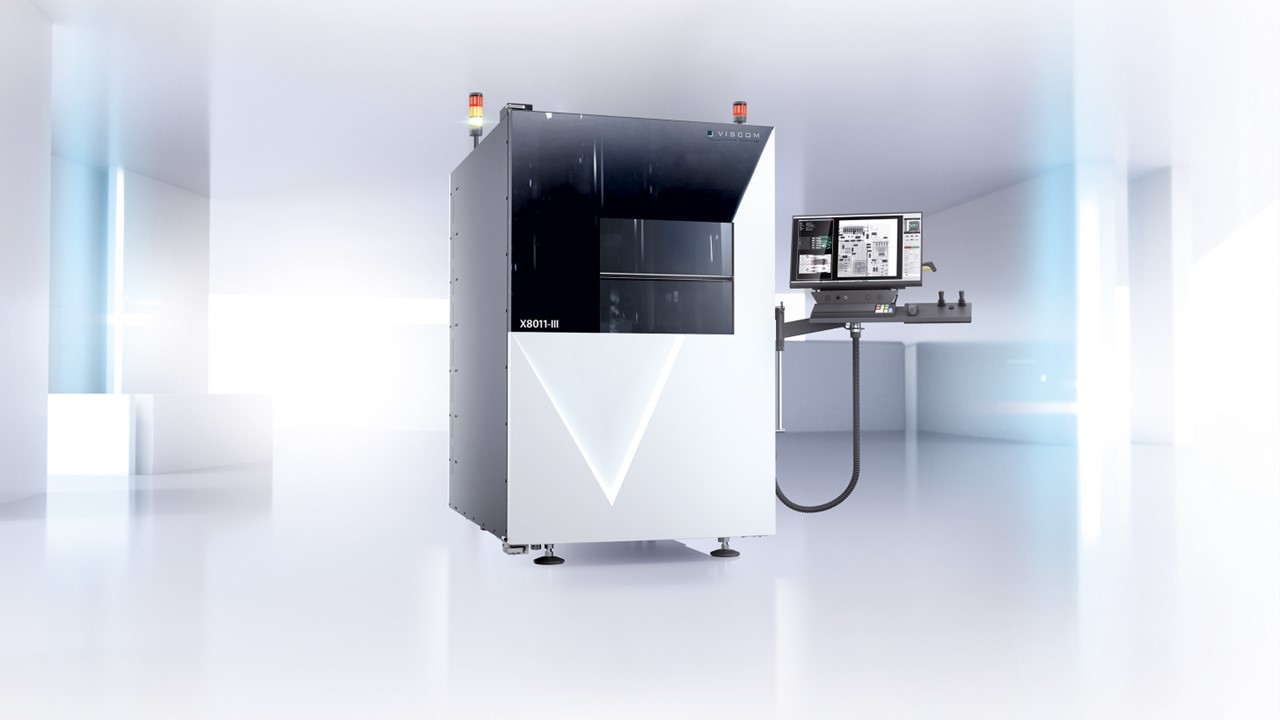

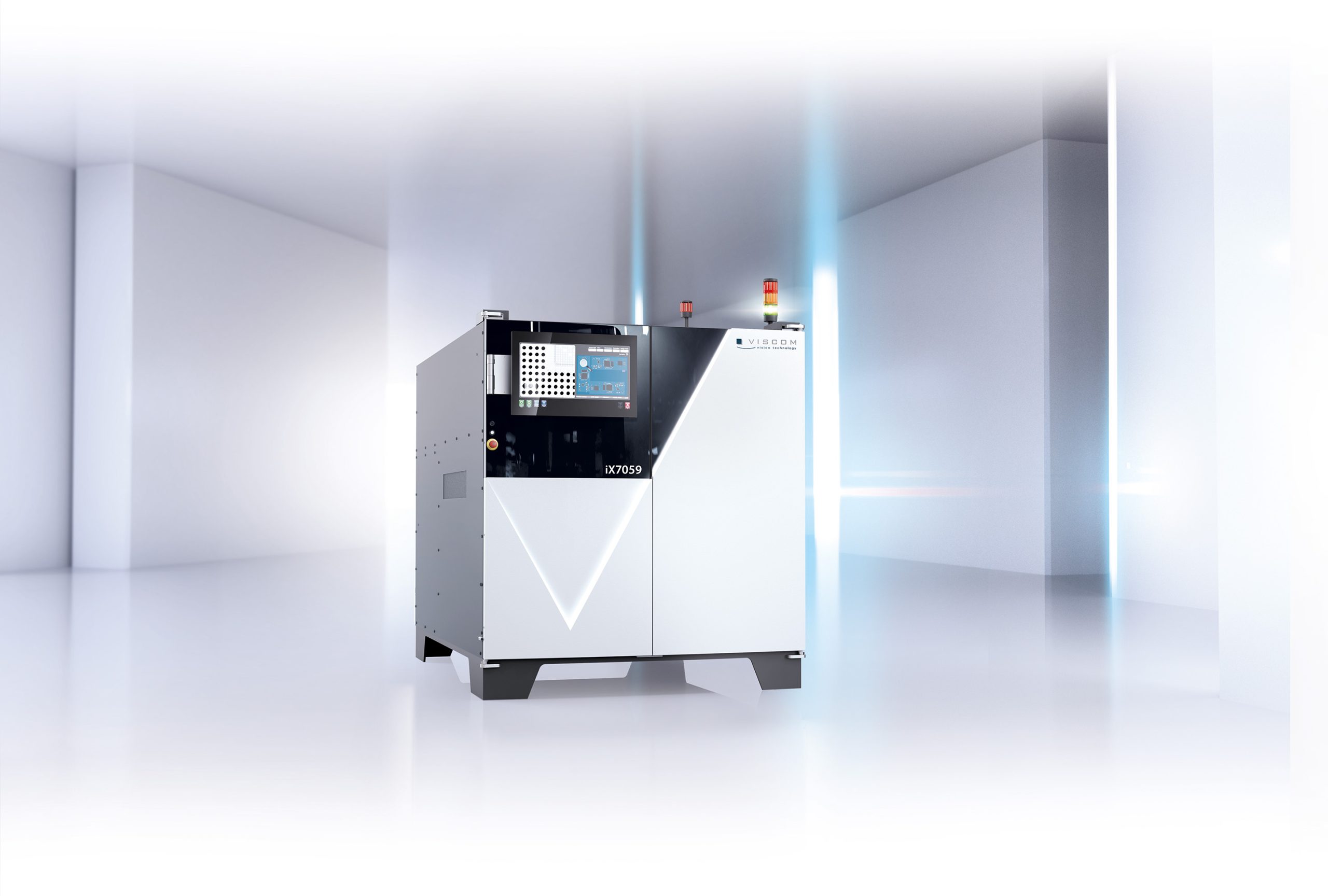

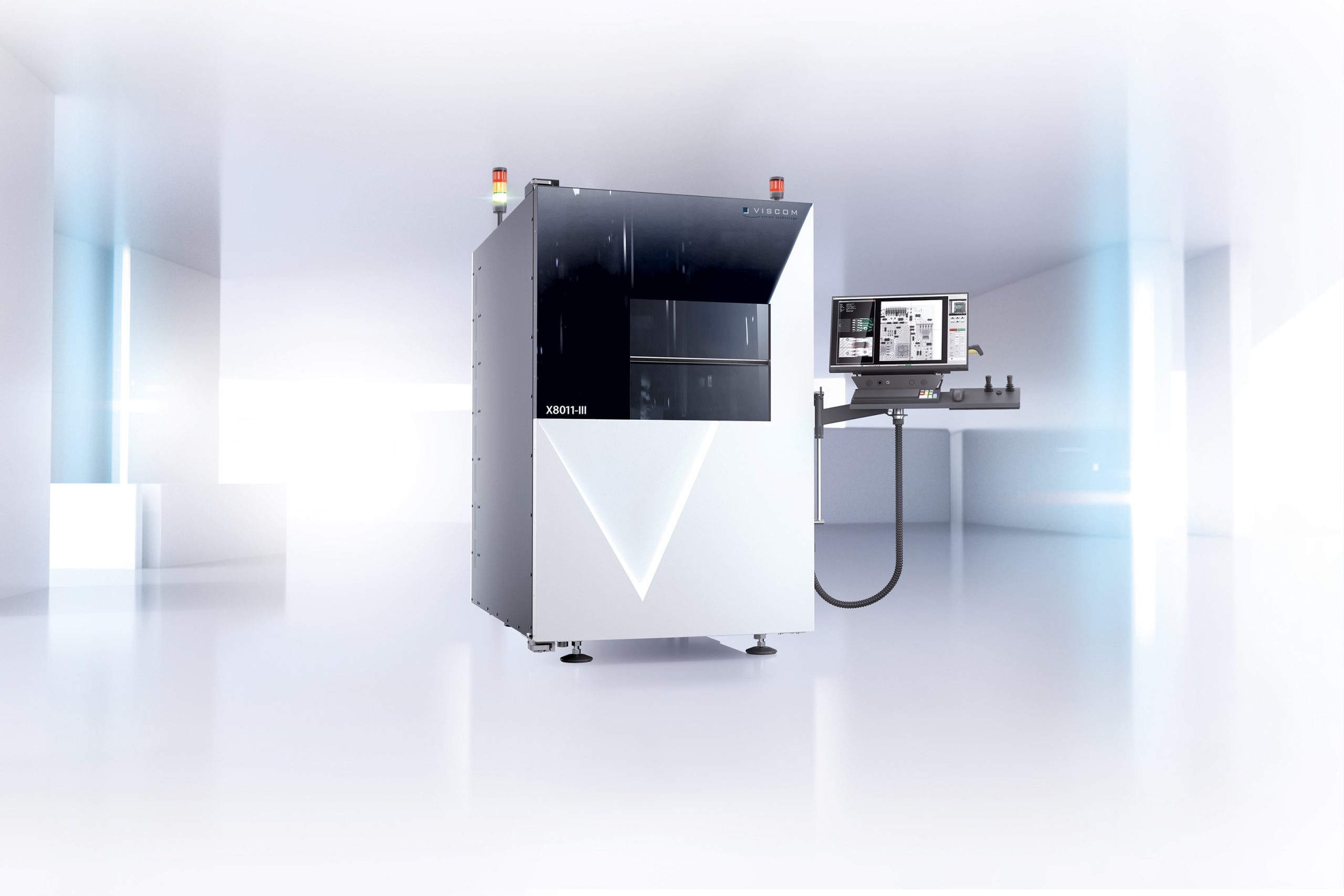

What cannot be inspected optically, such as voids in solder joints, is measured and analyzed using state-of-the-art 3D-AXI methods. Depending on the configuration, the award-winning systems of the iX7059 series from Viscom can inspect flat assemblies up to a length of 1600 mm or, e.g., inspection objects weighing up to 40 kg, using X-ray technology. For prototypes, small series, or in case of customer complaints, the X8011-III semi-automatic X-ray system is the perfect solution, which, like the S3088 ultra chrome SPI, will be shown for the first time at an Asian trade show during NEPCON China 2023. Another special highlight: A virtual showroom at the Viscom booth offers an even much larger system overview. Users can move from machine to machine on the screen and call up relevant information.

The manufacturing of the inspection systems is located at the main site of Viscom AG in Hanover, Germany – together with the development of the associated software. An important feature of the ready-to-use applications is, for example, the networked access to results from all inspection gates. The modular vConnect platform, in turn, offers a broad portfolio of innovative and individually scalable digital services ranging from condition monitoring and IT management services to high-performance storage solutions. Real-time data and analyses can be accessed and controlled from devices like a smartphone, tablet, or desktop PC. This makes it possible, for example, to implement cross-site predictive maintenance very efficiently.

For more information, visit www.viscom.com.