Heraeus Electronics is pleased to announce the development of a production friendly, flexible passive component termination ink. ET2010 Flexible End Termination Ink is a first of its kind material in the market utilizing advanced polymer technology. When compared to current thermoset, epoxy-based inks in the market, Heraeus’ solution offers easier shipping, storage, and handling at room temperatures.

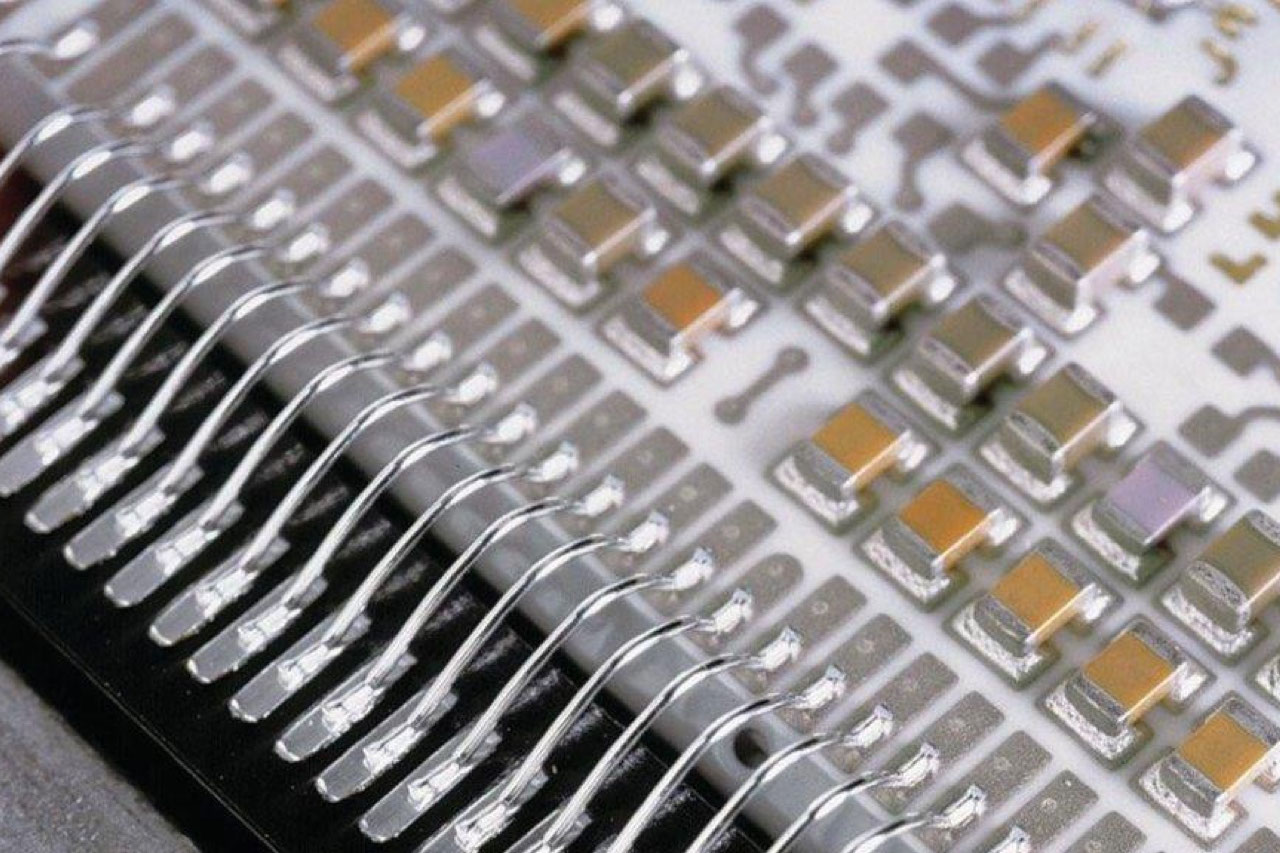

Manufacturers of passive electronic components, such as multi-layer ceramic capacitors, chip inductors, chip varistors, chip resistors and chip fuses are accustomed to handling electrode and termination inks in room temperature conditions, except for their flexible termination inks. Current flexible termination inks use epoxy based, thermoset polymers that require deep freezing and special handling conditions to keep the epoxy from reacting.

Passive component requirements continue to grow with increased usage especially in the Automotive, Consumer, and Industrial electronics industries. In Automotive, current ICE automobiles contain 2000-3000 capacitors for example. This will grow by 5-10x (15-20k capacitors) in EV, and brings further focus on reliability and safety given media and financial impacts from product recalls. This also is applicable for nearly all other high reliability applications where impact testing, vibration, or thermal stability are concerns. The value (pricing) of these high-reliability components is expected to increase as well.

Heraeus’ new ET2010 can provide these improvements in reliability as well as provide a production friendly solution to the industry standard epoxy materials. Cost of ownership for the customer was kept fully in mind during development – shelf life, shipping, storage, paste utilization, and scrap savings on silver are all improved compared to current materials.

The easy-to-use, reworkable ET2010 ink offers room temperature stability for six months, a significant benefit compared to epoxy-based pastes that need to be frozen or refrigerated. The optimized chemistry is composed of high temperature thermoplastic instead of thermoset (epoxy) – making it more tolerant to thermal cycling and offering enhanced flexibility. With ET2010 there is no need for ice packs/dry ice, which translates to lower shipping costs, a low scrap rate (Ag savings), as well as eliminating costly storage. Additionally, its low silver (Ag) content – approximately 5-10% lower Ag content – provides significant savings given today’s Ag market pricing.

A drop in solution, ET2010 stands for improved reliability with superior bend test capability of up to 10 mm with minimal electrical property change, in addition to providing excellent moisture resistance and solder heat resistance.

To learn more about Heraeus Electronics, visit heraeus-electronics.com.

About Heraeus

The Heraeus Group is a broadly diversified and globally leading family-owned technology company, headquartered in Hanau, Germany. The company’s roots go back to a family pharmacy started in 1660.Today, the Heraeus group includes businesses in the environmental, electronics, health and industrial applications sectors. Customers benefit from innovative technologies and solutions based on broad materials expertise and technological leadership.

In the 2021 financial year, the FORTUNE Global 500 listed group generated revenues of €29.5 billion (US$34.9 billion*) with approximately 16,200 employees in 40 countries. Heraeus is one of the top 10 family-owned companies in Germany and holds a leading position in its global markets.

About Heraeus Electronics

Heraeus Electronics is a leading manufacturer of materials for the assembly and packaging of devices in the electronics industry. The company develops material solutions for the automotive, power electronics and advanced semiconductor packaging market and offers its customers a broad product portfolio – from materials and material systems to services.