Solarnative Germany is investing 1 Mio. Euros in a brand new SMT production line for their new facility in Hofheim am Taunus in Germany. This first production line from JUKI Automation Systems marks the start of a new prospering journey and is an important step in the growth plans of Solarnative. This growth was one of the main reasons Solarnative selected SMT Renting as their financial partner in this deal.

With this first step, Solarnative, SMT-Renting and JUKI are kicking off their strategic partnership to set up a solar micro-inverter Gigafactory in Germany. Solarnative’s goal is to ramp up the manufacturing of their unique high frequency micro-inverter starting in May 2023 and expand the production capacity to more than a gigawatt within the first years. According to Julian Mattheis, CEO of Solarnative Germany, the investment in this new SMT (surface-mount technology) line will support the growth ambitions of the startup company. “Through SMT Renting we can avoid high CAPEX since the monthly lease cost are booked as operational expenses. This way we can keep the money in the company, which is needed for our fast growth. Furthermore, we see that the technology is changing rapidly, and we expect the equipment to be upgraded or replaced within the next few years. The SMT Renting concept supports this and therefore it suits us very well”, Julian explained. Apart from the initial equipment, Solarnative is planning to expand the SMD line in Q3 2023 with another 0.5 Mio Euro investment to increase the production capacity by 50%. Further investments are scheduled for Q2 2024.The new production line is a total line solution from JUKI Automation Systems. As a one-stop-shop supplier, JUKI supplies a state-of-the-art flexible production line for each step of the SMT process. Next to the SMD line JUKI will also deliver the logistic solution to automatically manage the supply of the electrical components that are needed at the SMD line.

Alex Nies, Business Manager at SMT Renting commented: “I’m very pleased that we could support both Solarnative and JUKI in the equipment selection process and could find a financial solution for such an aspiring startup company.”

The requirements of Solarnative in their production process go beyond the typical SMT production process. This is one of the reasons why Solarnative is not simply outsourcing the production but wants to have full control over the entire process. The very thin printed circuit boards (PCB) cannot be separated and processed as they would be in a standard electronic manufacturing process.

“It was not easy to find the right SMT line supplier for us,” commented Robert Wade, Project Manager at Solarnative. “We not only need the equipment, but it also turned out there is no such thing as standard equipment in the market to meet our technical requirements without adaption. With JUKI we have found a partner, who is willing to take on the task and not to only sell their equipment off the shelf. They have a proven track record of adapting their machines to special requirements. Furthermore, they help us with the customization of the processes.” he continued.

JUKI, with their European Headquarter located in Germany, has sent their Sales and Product Managers, to figure out the best possible solution. In close collaboration with their partners and Solarnative, the innovative approaches to customize not only the handling process, but also the glue dispensing process as well as the soldering requirements, has been developed and is currently in the making.

“We are very enthusiastic about being part of this project”, says Stephan Leng, Head of Technical Sales at JUKI Automation Systems. “It is not the first time that we were capable to make things happen where other vendors dropped out. JUKIs own product management here in Europe, and our installation team make the big difference.” And Thomas Kempf, Head of Sales at JUKI Automation Systems explains: “We customize many machines according to our clients’ particular needs, this is nothing new to us. We consider ourselves a partner, not a supplier.”

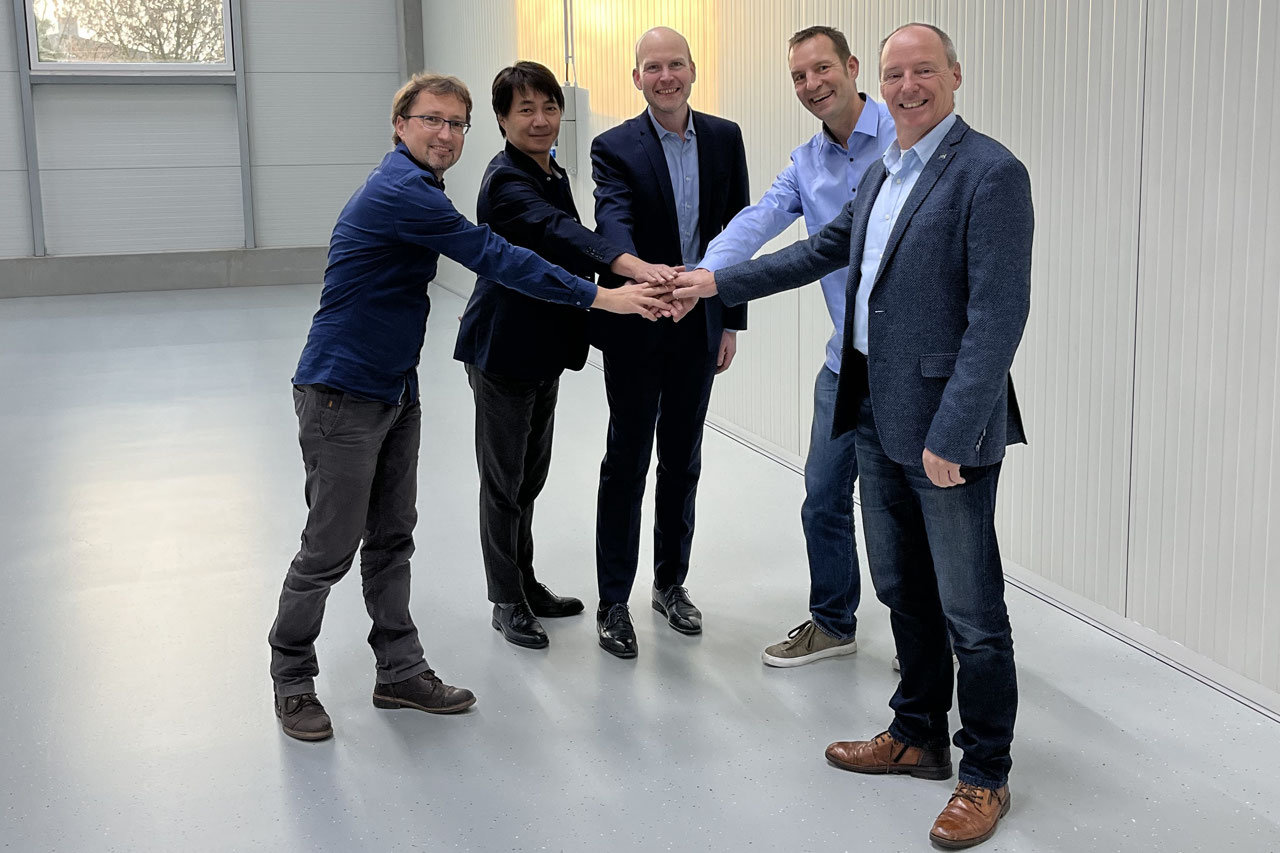

*The picture featured is taken in the new facility of Solarnative. From left to right: Robert Wade (Solarnative), Kenji Hirohata and Thomas Kempf (JUKI), Julian Mattheis (Solarnative) and Alex Nies (SMT Renting)

About

Solarnative is a startup company in the photovoltaic industry based in Frankfurt, Germany. With its Smart Energy Home, the company aims to revolutionize the market: the modular plug & play system ensures maximum yield and safety at the same costs, compared to standard PV systems. Founded in 2019 by Henk Oldenkamp and Julian Mattheis, the company currently employs 20 people at two locations. In Hofheim am Taunus, Germany, Solarnative is now setting up their own production facility aimed to become a Smart Gigafactory with an annual capacity of 3M inverters within the next years.

SMT Renting is a financing company specialized in renting solutions with SMT Equipment from the top suppliers within the Electronic Manufacturing Industry and was founded in 2015.

With over 30 years of experience in the Electronic Manufacturing Industry SMT Renting have a unique in-depth know-how about the electronic production equipment market.

This allows us to tailor a unique and flexible financing solution for your company that includes service and technical benefits that are incomparable with traditional Leasing & Bank financing models. Our mission is to deliver the most flexible renting solutions for the Electronic Manufacturing Industry to help our customers stay competitive.

JUKI Automation Systems supplies leading SMT assembly solutions for the Electronic Industry throughout the world. Customers typically have their roots in EMS – Electronic Manufacturing Services, Automotive, Industrial and Consumer Electronics. From its European headquarters in Nuremberg, Germany, JUKI Automation Systems GmbH distributes perfectly tailored SMT solutions to satisfy customer needs throughout Europe. JUKI Automation Systems GmbH is part of the JUKI Corporation – a market-listed Japanese company with almost 6,000 employees in the business areas of electronic assembly systems and sewing machinery. JUKI is pioneer in introducing modern, modular placement and in doing so presented the first placement machine to the market in 1987.