SMT dominates the majority of PCBA, but through-hole technology refuses to go away. In the current climate, where developments in power applications for rechargeables, converters and drive systems are significantly increasing, and the sudden upturn in aerospace and defense contracts with ruggedized applications, the efficient assembly of through-hole is still a relevant and crucial part of production.

The main reason for clinching a component leg was to form a mechanical fix to the PCB, principally to retain the part when being handled or stored prior to soldering; secondly to avoid movement of components during wave soldering. These two situations still cause issues today where the movement of components can and will occur. That’s why Robotas Technologies, the world’s leading hand assembly specialist, has developed the Mascot Clinch System to provide Clinch technology for today’s demanding, smart production requirements.

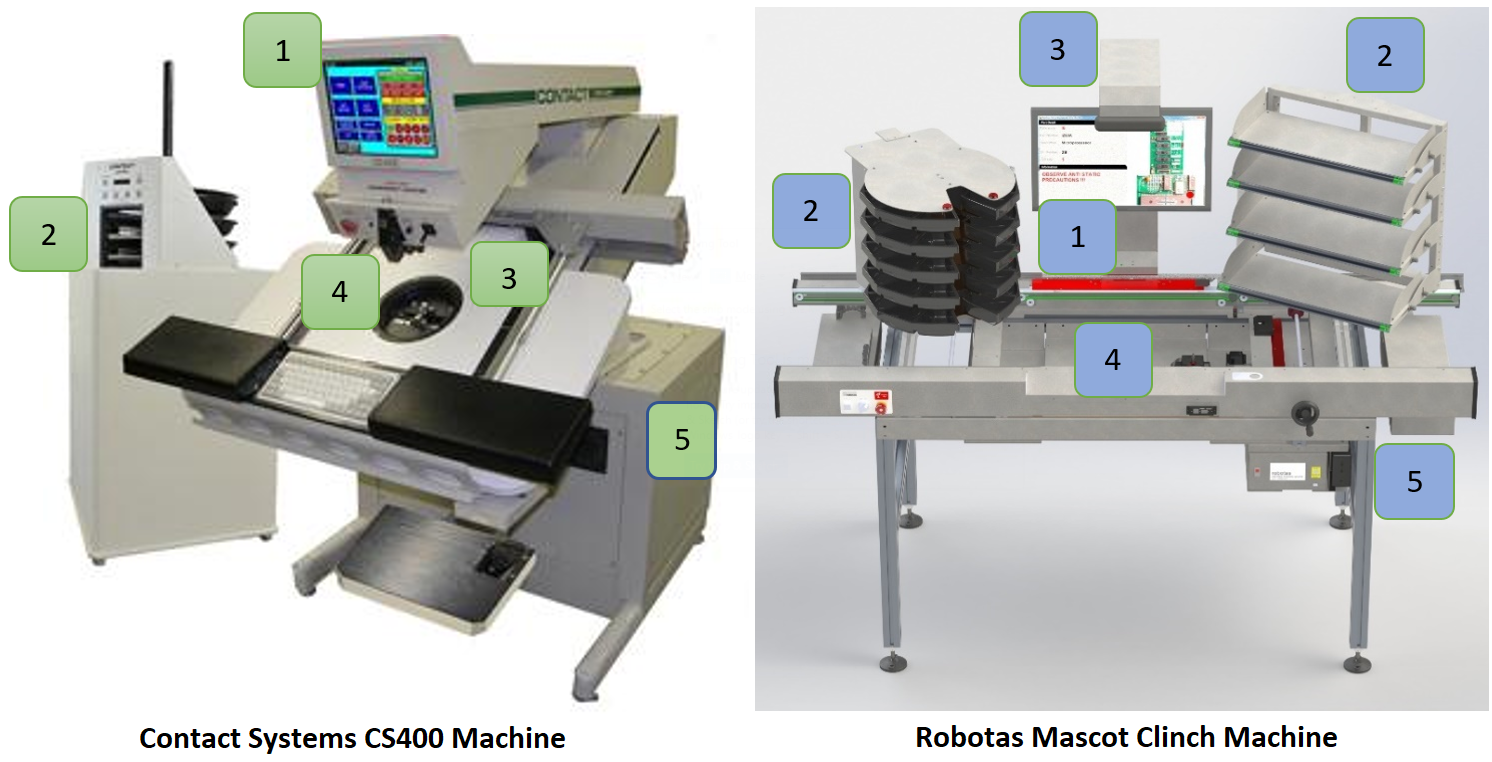

In its day, the Contacts Systems CS400 unit was on the cutting-edge of Clinch Technology in PCBA. The unique mechanical design and versatility of their system led it to be widely adopted on production floors across the USA. However, does this assembly method still have a place in production today?

Click here to read Robotas’ comparison between Contacts Systems CS400 system against Robotas’ new Mascot Clinch System: www.robotas.com/cs400-comparison.