At the end of 2022, Rehm Thermal Systems in Blaubeuren had an agenda packed full of various information events relating to the world of electronic assemblies. In particular, the seminar “Protecting electronics from A to Z” attracted a lot of attention. Rehm’s experts talked about all the important issues surrounding effective and sustainable protection of printed circuit boards for electronic components in front of an interested audience.

On-site seminar: Protecting electronics from A to Z

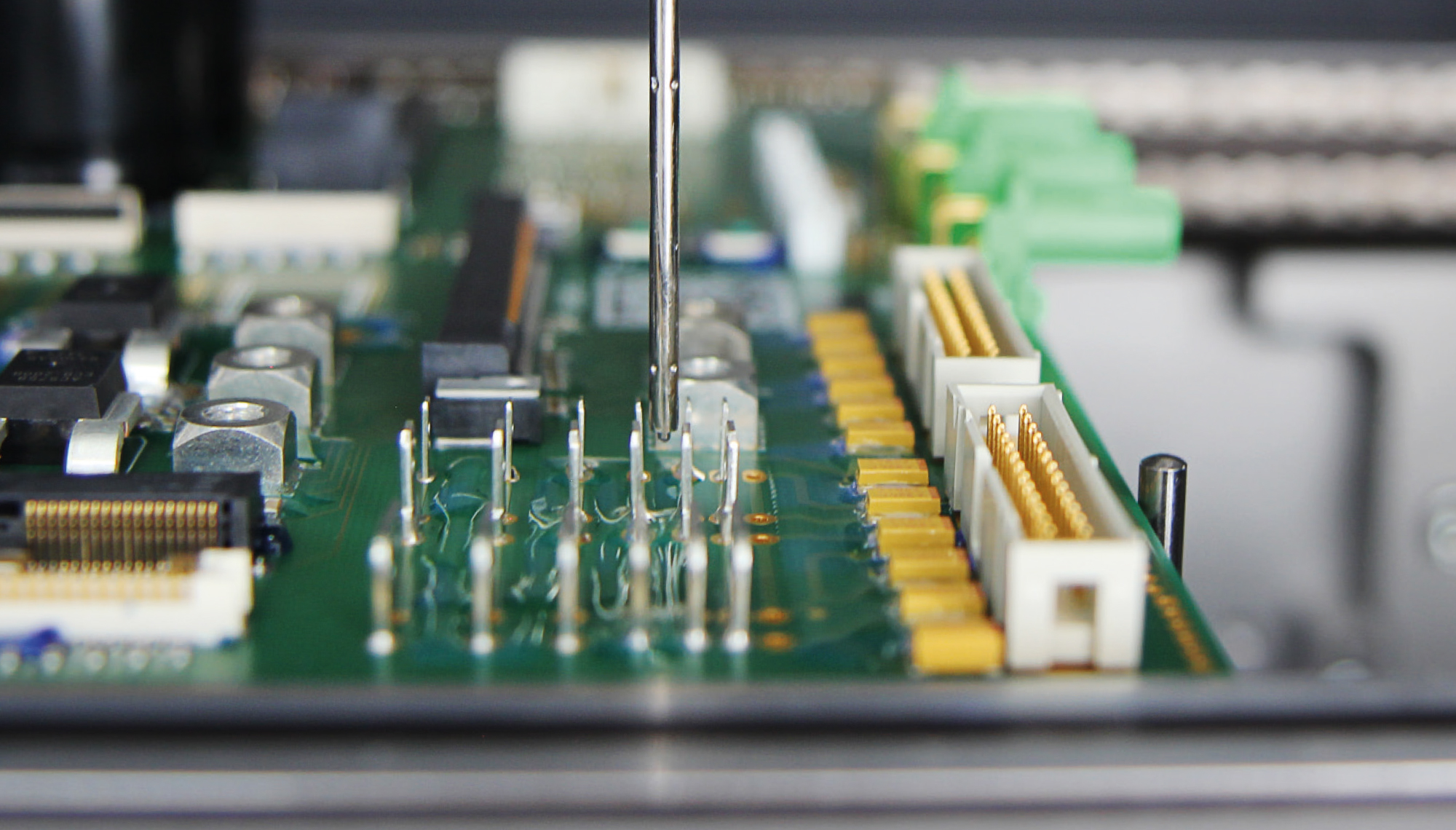

Whether in consumer electronics, automotive and avionics, building and household technology, medical technology or renewable energies, sensitive electronics are becoming increasingly powerful and compact. At the same time, however, industry requirements regarding quality are growing, previously unknown error patterns are emerging – and new hurdles are appearing. Whether humidity, dust, cold, heat, UV radiation or colonisation by mosses, fungi and microorganisms, the correct protection of electronic components is as necessary as it is complex. With the face-to-face seminar “Protecting electronics from A to Z”, Rehm informed interested audience members from industry and production about the basics and diversity of coating technology as well as about failure analysis during the production process and on the coated product. The discussions included possible failure scenarios from dendrite growth to creepage distances and signal distortions, but also the selection of available coatings and application processes as well as the correct handling of defects.

The conclusion of the face-to-face seminar was that protecting electronics is becoming increasingly important. Using the appropriate finishing not only extends the service life significantly, but also increases the quality of the coated product – and ensures that end customers are satisfied. At the other end of the spectrum, however, neglecting safety aspects can (depending on the application) even put lives in danger. High-quality, innovative bonding, dispensing and potting solutions as well as process technologies tailored to them offer solutions for every application.

Protecting electronics with the Protecto series from Rehm

As a technology leader, Rehm Thermal Systems is globally active in every industry and is very familiar with the wishes of its customers. Accordingly, the Protecto series from Rehm delivers safe, automated processes and precise results in the application of a wide range of materials. Up to four applicator heads can be used at a time, offering users a wide range of options and the most diverse material bonding. In addition to dispensing, this includes the ability to create freely definable, three-dimensional housings through simple application, the immediate curing of UV varnishes and the potting or bonding of different materials. The modern and uniform ViCON software integrates all available Rehm systems and enables intuitive operation and fast project creation.

About Rehm Thermal Systems

As a specialist in the field of thermal system solutions for the electronics and photovoltaics industry, Rehm Thermal Systems is one of the leaders of technology and innovation in the modern and economical production of electronic assemblies. As a globally active manufacturer of reflow soldering systems with convection, condensation or vacuum, drying and coating systems, function test systems, equipment for the metallisation of solar cells and numerous customer-specific special systems, we are represented in all relevant growth markets and, as a partner with more than 25 years of experience in the industry, implement innovative manufacturing solutions that set standards.

For more information, please visit www.rehm-group.com.