Ultrasonic wire bonding has been established as a contacting method in the microelectronics and semiconductor industry for many years. The technology is also ideally suited for electrically interconnecting battery cells. To ensure one of the most important prerequisites for high-quality and durable connections – a clean bonding surface – F&S Bondtec Semiconductor and acp systems have entered into a worldwide cooperation. The agreement means that wire bonding systems with integrated quattroClean snow jet cleaning can be supplied from a single source.

The fully automatic and manual wire bonding and bond testing equipment from F&S Bondtec Semiconductor GmbH are used around the world by large and medium-sized companies in the microelectronics and semiconductor industries, as well as in development departments, pilot production facilities and university laboratories. By contrast, the family-run company from Braunau am Inn in Austria, which was founded in 1994, has only recently started manufacturing battery packs, for example for e-mobility applications, battery-powered tools and stationary energy storage systems. The advantages of wire bonding include its versatility and productivity as well as the high reliability and durability of the connections. “But this can only be achieved if the cleanliness level of the bonding surfaces is consistently high,” explains Johann Enthammer, technical manager at F&S Bondtec. Especially particulate and chemical-filmic impurities due to organic contaminants or oxidation, for example, are a problem. However, fluctuating storage conditions or storage times of the cells can also affect bonding results. “Particularly when it comes to sectors such as the automotive and supplier industries, customers are not sufficiently aware of the importance of cleanliness. To be able to offer added value in this context, we searched for an effective, integrable and comparatively low-cost cleaning solution,” says Johann Enthammer.

quattroClean snow jet cleaning meets requirements

The technical manager found what he was looking for at his neighboring booth at the Productronica 2019 trade fair – acp systems AG, developer and manufacturer of the quattroClean snow jet cleaning technology and automation solutions. Together with the company, which is already experienced in realizing cleaning applications for the electronics and semiconductor industries, F&S Bondtec conducted trials. “For one, we achieved reproducible and convincing results. For another, the cleaning process does not cause any mechanical changes to the bond surface, a phenomenon we have observed in trials with laser cleaning which can affect the quality of the bonds over time. In addition, the quattroClean process is easy to implement,” says Johann Enthammer, citing some of the reasons that were decisive for the cooperation with acp systems.

Targeted, dry and sustainable cleaning process

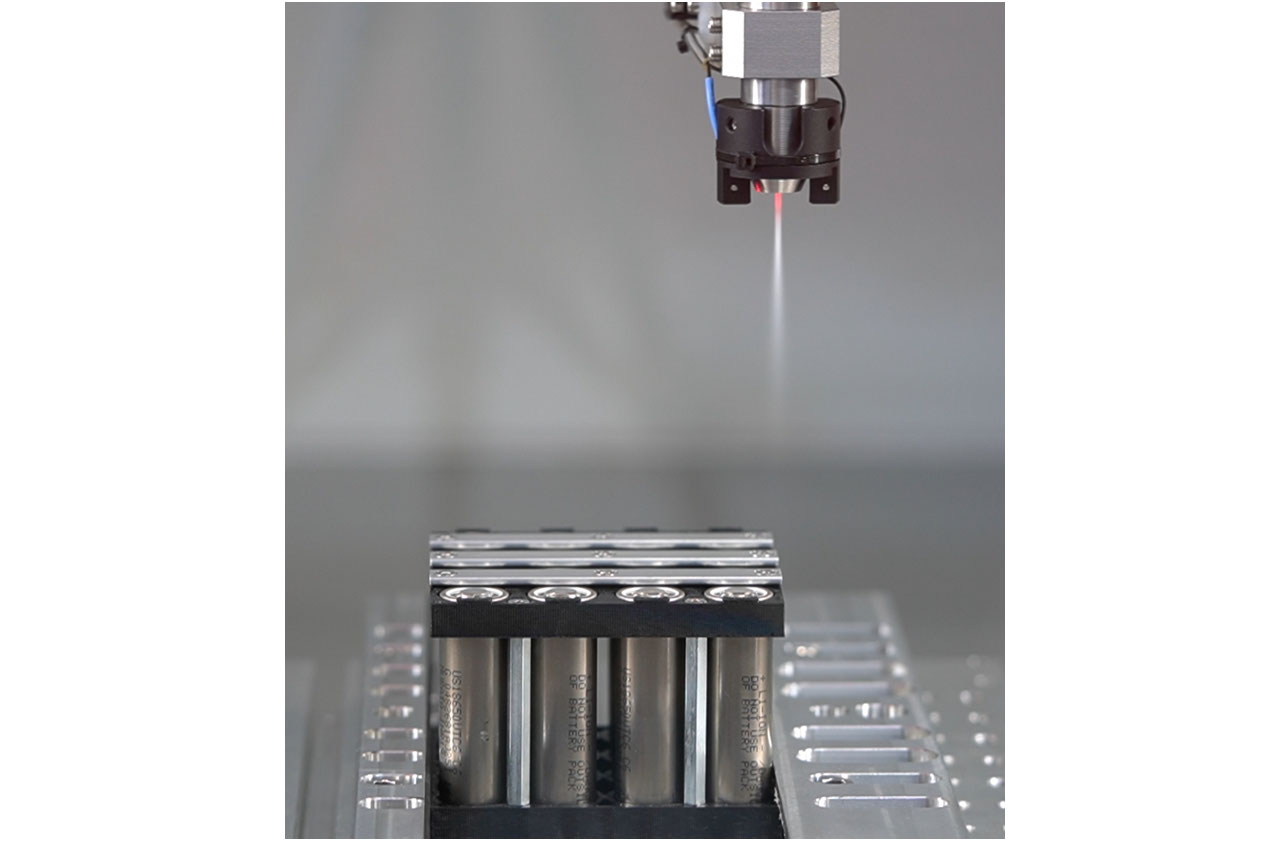

The cleaning medium used in this dry, climate-neutral technology is liquid carbon dioxide, which is obtained as a by-product from chemical processes and from the generation of energy from biomass. Guided through a wear-free two-component ring nozzle, the carbon dioxide expands on exiting to form fine snow crystals, which are then bundled by a separate jacket jet of compressed air and accelerated to supersonic speed. The jet is easy to focus on a specific area. On impacting on the surface to be cleaned, four mechanisms (thermal, mechanical, solvent and sublimation) ensure that organic impurities and particulate contaminants even in the sub-micron range are reliably and reproducibly removed. After cleaning, the surface is optimally prepared for the subsequent bonding process. Since the crystalline carbon dioxide sublimates completely during cleaning, surfaces are dry and ready for the wire bonding process straightaway.

Compact cleaning solution for fully automated and manual operations

The compact and scalable quattroClean system is designed so that the cleaning process can be integrated fully automatically, for example into the Series 86 bonding machines for large-scale battery packs. The quattroClean nozzle is fitted to the bonding head and integrated into the machine control system so that all surfaces to be bonded are automatically approached with optimized path control and cleaned in a defined manner prior to bonding. Solutions for manual cleaning and bonding can also be implemented, as can complete production lines with automated parts handling.

To guarantee consistently good results, the consistency of the snow jet is monitored at each nozzle by a sensor system. The supply of compressed air and carbon dioxide to the nozzles, as well as the jet time, is also monitored. All values measured are stored automatically and can be transmitted via standard interfaces to a higher level system to collect and store all production data.