PulseForge, Inc., a new spinoff of NovaCentrix, will discuss their breakthrough soldering tools at SMTconnect, scheduled to take place May 10-12, 2022 in Nuremberg. PulseForge® soldering tools are poised to redefine EMS through a combination of the novel design freedoms they enable, as well as the dramatic reduction in process energy utilization, towards decarbonizing the EMS supply chain.

PulseForge Inc.’s manufacturing technology is changing how products are designed through creating options for utilizing non-conventional and innovative materials while also improving costs and sustainability levels. The company’s technology experts will discuss its Batch and In-Line Soldering Tools, offering design and sustainability consultation at the event. The PulseForge Soldering Batch model is ideal for stand-alone processing requirements while the In-Line model is used for integrated production.

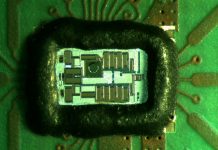

PulseForge Inc is bringing their proprietary thermal processing technologies to the EMS market after years of application in display, RFID and photovoltaics production. Sub-second heating and cooling means no damage to heat-sensitive substrates and components even when using SAC305 pastes on plastic, and direct-soldering coin cell batteries. Because of the ultra-fast thermal processing, energy utilization drops as much as 85 percent or more in comparison with conventional multi-zone reflow soldering.

PulseForge® Soldering was recently named winner for Global SMT & Packaging’s Global Technology Award for Best Product North America 2021 as well as being a Mexico Technology Award 2021 recipient.

Product design trends in applications such as AR/VR/XR, medical and consumer wearables, and automotive are increasingly moving towards the use of thinner, flexible, less expensive substrates and/or low-temp components. This shift though brings a manufacturing challenge: how to solder these low-temp materials without damage and at economical scale. With PulseForge tools, product innovators and manufacturers can now utilize novel flexible, low-cost materials and components, and deliver scaled, reduced-energy functionality never before possible.