Whether for downstream processes or to ensure the lasting and reliable function of a product, rising requirements for particulate and filmic-chemical component cleanliness are increasingly causing cleaning tasks to be shifted to clean environments. For these applications, acp systems has developed the new JetCell-HP, an innovative cleaning cell with dry quattroClean snow-jet technology that has been specially designed for use in cleanrooms. The compact and digitally controllable solution performs a wide variety of cleaning tasks automatically, either inline or as a stand-alone device.

In industries such as the medical device sector, pharmaceutics, optics, sensor & laser technology, metrology, semiconductor supplier industry, electronics and microtechnology, the cleanliness specifications for parts and components are becoming ever-more stringent. Consequently, there is a growing need to shift cleaning processes to clean environments. This is because particulate contamination even in the submicrometer range is sufficient to impair the quality of processes and products, as can the finest filmic residues, stains and fingerprints. To solve these cleaning tasks in a reliable, scalable, consistent and economical way, appropriately-adapted equipment is indispensable.

Cleanroom compatible dry cleaning cell

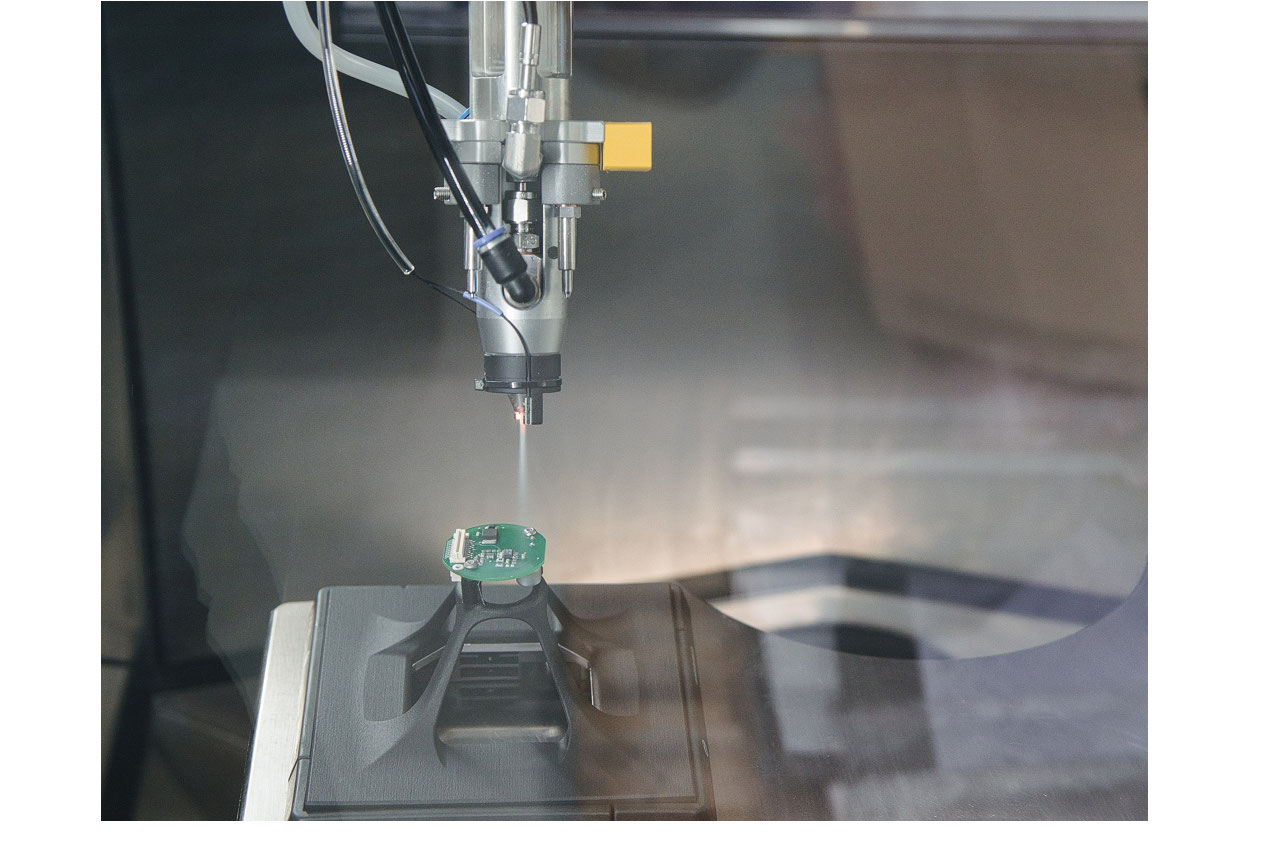

Such a cleaning solution is offered by acp systems AG – its new quattroClean JetCell-HP cleaning cell with snow-jet cleaning technology in cleanroom-compatible design. The cleaning process is dry and uses climate-neutral carbon dioxide.

The compact cell for flexible automated production is made entirely of stainless steel and has smooth, homogeneous surfaces without any external screws. It can be easily integrated into a connected production line or operated as a stand-alone device. All equipment components and materials are geared to cleanroom applications. Thanks to the flow-optimized design of the process chamber, detached impurities and sublimated carbon dioxide are removed quickly and effectively by the integrated extraction unit. This effectively prevents not only cleaned parts from becoming recontaminated but also dirt pockets from forming.

To ensure a consistently superior cleaning result, JetCell-HP is fitted with a sensor system as standard that continuously measures the density of the snow jet. The digitally controllable cleaning cell can be easily integrated into and controlled by higher-level host computer systems via standardized interfaces. To ensure full documentation and traceability, all process parameters such as CO2 supply, compressed air supply and jet time are recorded automatically and transferred to the host computer.

The quattroClean technology – cleanliness achieved by four effects

The key to the quattroClean system’s excellent cleaning effect is the design of the wear-free, two-substance ring nozzle through which the liquid carbon dioxide is fed. This expands on exiting to form fine snow crystals, which are then bundled by a separate jacket jet of compressed air and accelerated to supersonic speed. The jet is easy to focus on a specific area. On impacting on the surface to be cleaned, four mechanisms (thermal, mechanical, solvent and sublimation) ensure that particulate and filmic-chemical contamination are reliably removed. The crystalline carbon dioxide sublimates completely during the cleaning process. The surfaces/parts are therefore dry and can be advanced immediately to the next production step. The cleaning process is so gentle on materials that it can even be used to clean delicate and finely-structured surfaces.

Easy to adapt to different cleaning tasks

The scalable quattroClean process is easily adapted to different component geometries and can be used for partial or full-surface cleaning. The process is tailored and validated according to customer and application requirements through tests in acp’s technical center. The process parameters determined in this way can be stored in the JetCell-HP control system as part-specific cleaning programs. Besides the control system, the complete technology for the snow jet process as well as the media preparation equipment are also integrated into the system housing. The system is put into operation simply by hooking it up to the electricity, compressed air and carbon dioxide supply (cylinders or tank).

![acp_JetCell-HP_Rueckseite_V[1] acp_JetCell-HP_Rueckseite_V[1]](https://smttoday.com/wp-content/uploads/2022/05/acp_JetCell-HP_Rueckseite_V1.jpg)

About acp systems

The solutions from acp systems AG make it a global technology leader in advanced clean production, including process automation and system integration. The company was founded in 1997 and has its headquarters in Germany. Its core technologies include the resource-saving quattroClean snow jet cleaning, high-precision microdosing and smart handling solutions, for example for flexible materials and foils. acp assists electronics and automotive companies, as well as medical device manufacturers and others, in developing, planning, designing and integrating highly-automated and sustainable production processes.

Image credits: acp systems AG