In cooperation with its Mexico Sales Partner Repstronics, Koh Young, the industry leader in True3D™ measurement-based inspection solutions, is hosting a FREE Spanish webinar to help customers create smarter factories with AI-powered inspection solutions. The online seminar will begin at 1:00PM EST on Wednesday, 23 March 2022. Given the expected attendance for this trending topic, pre-registration for the free webinar is required: https://repstronics.zohobackstage.com/KohYoungInspection

“Right now, inspection plays an increasingly key role in making manufacturing smarter. Inspection allows us to deliver the quality we know is essential for the products being manufactured right now, and in the future,” commented Brent Fischthal, Senior Marketing Manager at Koh Young America. “It is providing the data that allow companies to improve their own performance and efficiency. Data from inspection is contributing to almost every process on the SMT line, supplying real insight into defects, as well as their root cause.”

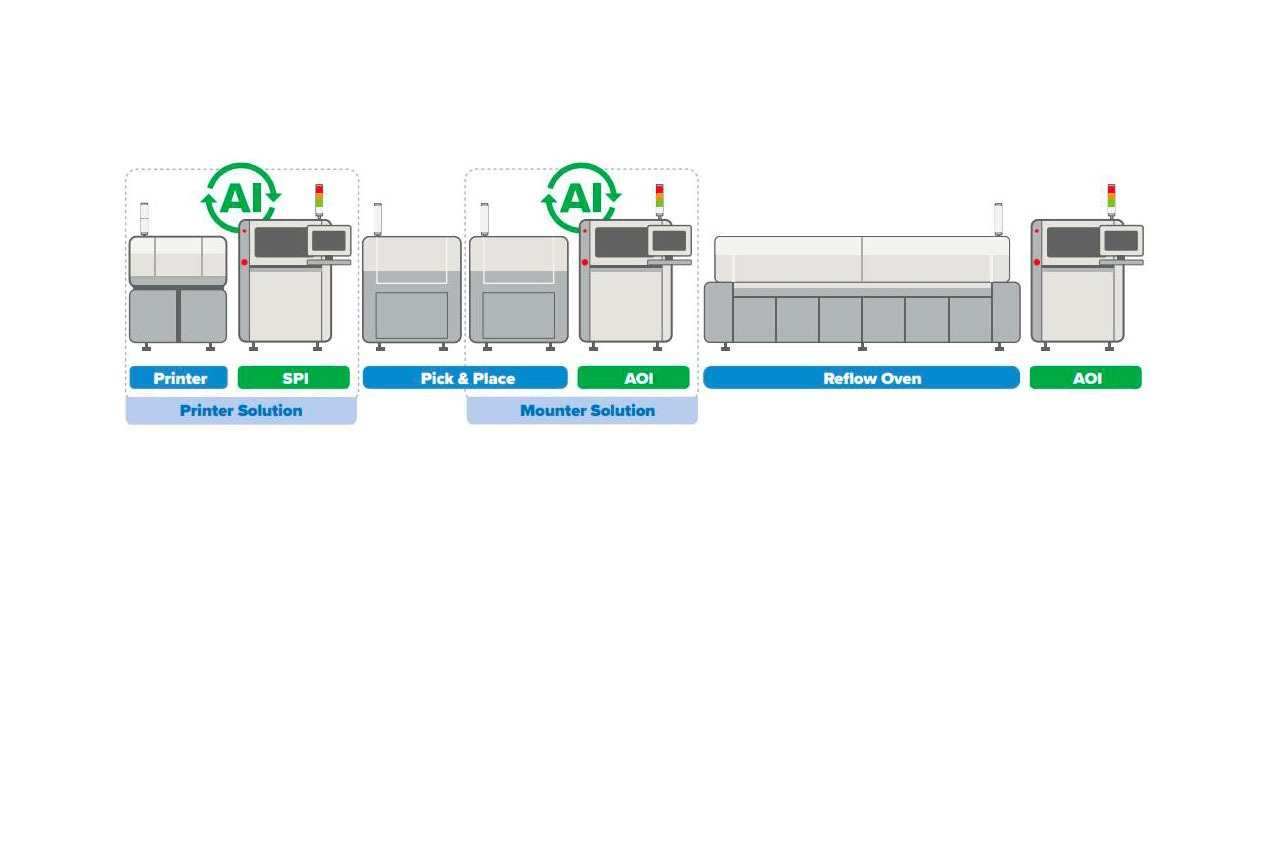

An industry dynamic changing the SMT line—and the whole manufacturing world—is the use of data to manage the process and drive towards a smart factory. This trend has helped manufacturers connect equipment and processes, so they can integrate the inspection data from solder paste inspection (SPI) and automated optical inspection (AOI) to improve electronics production metrics. Tools such as Artificial Intelligence (AI) and Machine Learning (ML) are used to analyze large data streams and produce better, faster decision-making that augments the operator by offering a path to autonomous manufacturing where the line will self-manage and improve its own performance. For companies to succeed in the development of a smart factory, manufacturers will need inspection solutions and equipment partners who can combine inspection and measurement expertise with machine-to-machine connectivity and AI.

“Reliable inspection systems have become powerful, economical complements to traditional test strategies. For example, SPI and AOI machines can be connected to the printer and mounter to monitor and improve the SMT production line,” stated Ramon Hernandez, Country Manager for Mexico and South America. “During this webinar, I will explore how manufacturers can optimize the PCBA [printed circuit board assembly] process by exchanging real-time SPI and AOI measurement data with other machines in the production line.”

To participate in this webinar, you must register at https://repstronics.zohobackstage.com/KohYoungInspection. If you cannot attend, visit our regional website at kohyoungamerica.com to learn more about our smart factory solutions.

About Koh Young Technology, Inc.

Established in 2002, Koh Young pioneered the market by launching the first 3D Solder Paste Inspection (SPI) system using a patented dual-projection Moiré technology. Since then, it has become the global leader in 3D measurement-based SPI and Automated Optical Inspection (AOI) equipment for the electronics industry. Based on its True3D™ measurement-based inspection technology, Koh Young has developed innovative solutions for challenges with Machining Optical Inspection (MOI), Dispensing Process Inspection (DPI), and Semiconductor Packaging Inspection (MEISTER Series). Through its technology innovations, Koh Young has secured thousands of global customers, and maintains the largest global market share in the SPI and AOI markets. Additionally, by adopting its user-centric R&D activities, it continues to leverage its core competencies and develop innovative solutions for new and existing markets. Its activities stem from the corporate headquarters in Korea to its global sales and support offices in Europe, Asia, and the Americas. These local facilities ensure it keeps in close contact with the market, and more importantly, its growing customer base to provide access to an award-winning network of inspection and measurement experts.

Learn why so many electronics manufacturers trust Koh Young for reliable inspection at kohyoung.com.

About Repstronics

Repstronics was founded in 2003 and has been offering solutions to the manufacturing industry for over 18 years. During that time, it has become a leading sales and service channel for innovative manufacturing solutions across Mexico and Central America. Its headquarters in Guadalajara is complemented by sales, demonstration, and training facilities in Monterrey and Ciudad Juarez, as well as its team of engineers located in strategically positioned cities across the region. With a line card of equipment and products to cover the entire electronics assembly line, Repstronics also delivers solutions for cables and harnesses, assembly and marking, and fiber optics, plus maintenance, repair, and operation (MRO) solutions for a variety of processes. By representing the industry’s leading brands, its team of experts and customer focus positions Repstronics as the ideal partner for manufacturers.

Learn more at repstronics.com.