Saki Corporation, an innovator in the field of automated optical and X-ray inspection equipment, is delighted to announce that FUJI Corporation has joined as SMT assembly system partner for Saki’s Job Data Conversion Function. The collaboration makes a direct data link for component information between FUJI’s mounters and Saki’s 3D-AOI possible.

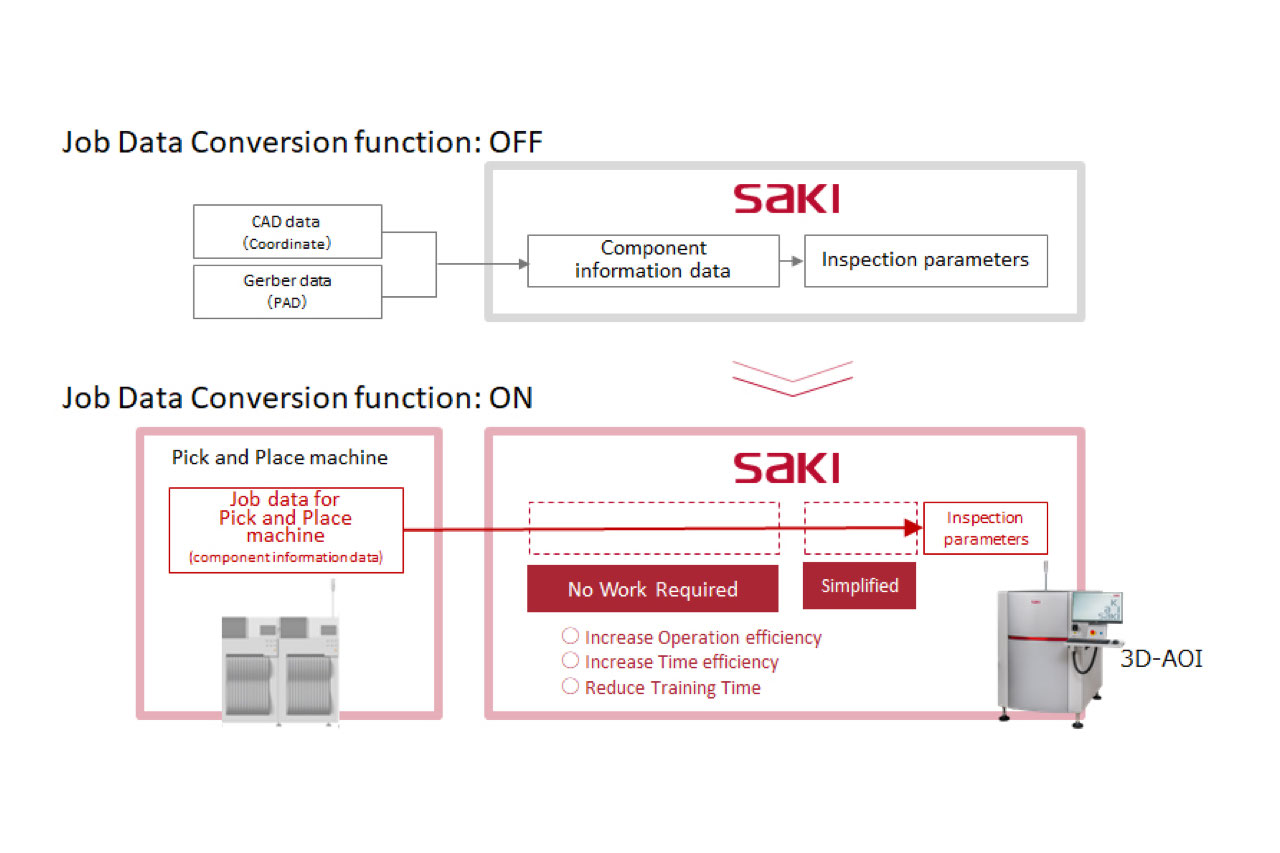

With the addition of the Job Data Conversion Function, Saki 3D-AOI system users can now automatically generate a PCB inspection data library by simply importing the component information data set from FUJI’s mounters directly into Saki’s 3D-AOI. The solution eliminates process duplication and man-hours required to create separate inspection data libraries for both FUJI’s surface mount machines and for Saki’s inspection systems and it significantly reduces the time required to create board inspection programs. The Job Data Conversion Function for FUJI SMT assembly system is scheduled to be available in the first half of 2022.

“Saki’s Job Data Conversion Function will further strengthen the data linkage between Saki’s extremely accurate 3D-AOI and our market-leading high-performance surface mount machines,” said Mr. Shinsuke Suhara, President and Chief Operating Officer of FUJI Corporation. “It will make a significant contribution to FUJI Smart Factory clients’ operational efficiency. We are sure that by collaborating, FUJI and Saki will provide a valuable and efficient Smart Factory solution to a greater number of customers, allowing them to boost the productivity of their SMT lines.”

Norihiro Koike, President and CEO of Saki Corporation commented: “We are delighted to be able to combine FUJI’s SMT equipment, which have a proven track record of excellent mounting accuracy, with the job data conversion capabilities of Saki’s board inspection systems in addition to existing M2M connectivity. Saki is committed to enhancing the quality and accuracy of its inspection systems and by further strengthening our relationship with FUJI, the leading manufacturer of SMT machines, we can offer a wide range of solutions to help our customers achieve a Smart Factory by enhancing the quality and productivity of their SMT lines.”

For a demonstration of the Job Data Conversion Function with FUJI Pick & Place machines, customers are invited to visit Saki’s Tokyo Digital Innovation Center (Showroom).

For further information about Saki visit, visit sakicorp.com/en/

About Saki Corporation