Hentec Industries/RPS Automation, a leading manufacturer of selective soldering, lead tinning and solderability test equipment, is pleased to announce that AEM Incorporated has invested in a Photon steam aging system.

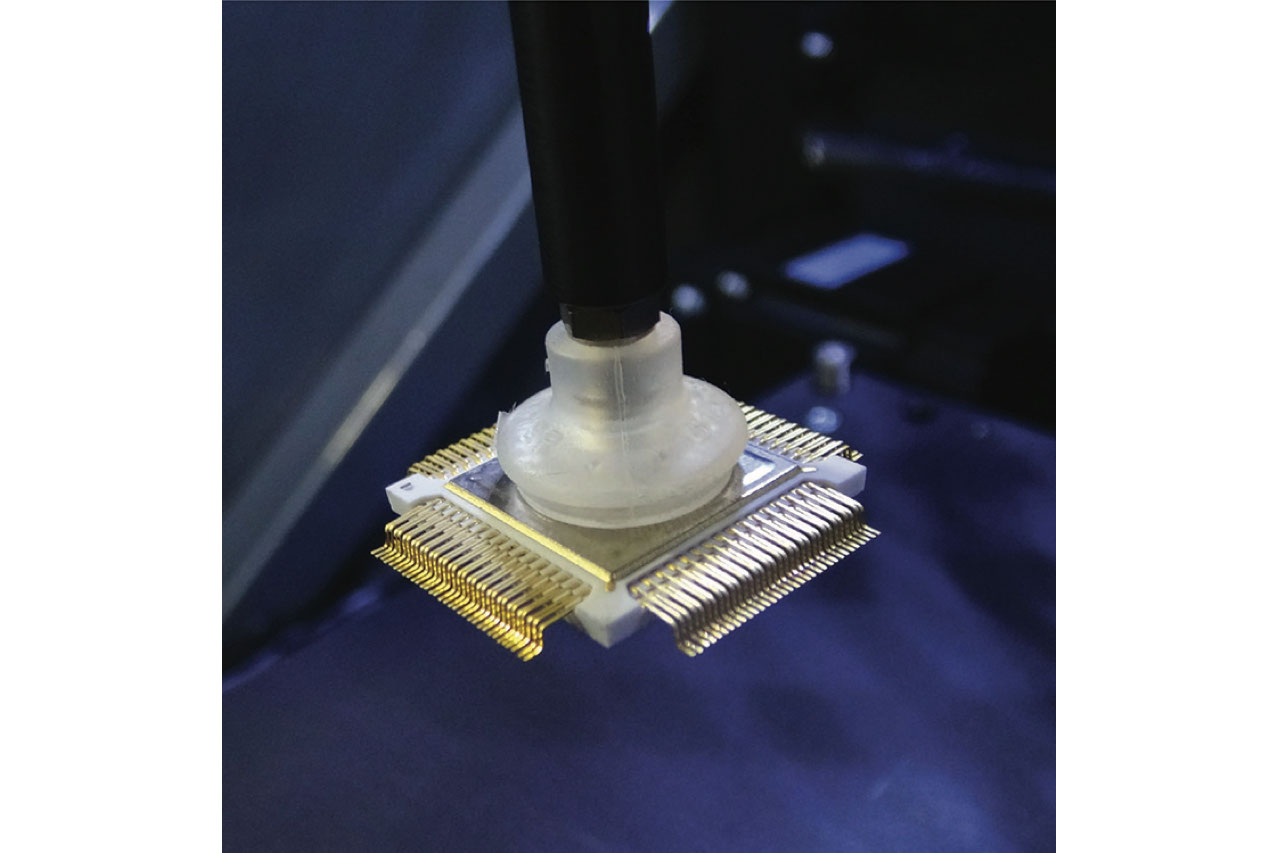

The Photon steam aging system is used for accelerated life testing to simulate elongated storage conditions for high-reliability applications. The Odyssey component lead tinning machines are specifically designed to perform component re-tinning, tin whisker mitigation, gold removal and BGA de-balling for high reliability and military application in accordance with all relevant GEIA-STD-006, MIL-PRF-38535, MIL-PRF-38524E and ANSI-J-STD-002 standards.

“AEM, Inc. is a longstanding customer of Hentec/RPS, and they have previously purchased a Pulsar solderability tester with this Photon steam aging system complementing their lead-tinning services,” said Reid Henry, President of Hentec/RPS

About AEM Incorporated

Founded in 1986, AEM Inc. is an award-winning company offering leading technologies in electronic components plus manufactured solutions and application specific services to high reliability OEM markets. Their primary products include hi-reliability fuses and ferrite devices as well as tin whisker mitigation services.

For more information, please visit aem-usa.com

About Hentec Industries

Hentec Industries/RPS Automation is a manufacturer of automated selective soldering, component lead tinning, and solderability test equipment for electronics and electronic component manufacturing, assembly, and distribution. Hentec/RPS has been advancing automated soldering and lead finishing technology for defense, aerospace, automotive, contract manufacturers and micro-electronics component manufacturers since the early 90’s. All Hentec/RPS products are designed and manufactured in Newman Lake, Washington.

For more information, please visit us at rpsautomation.com