Current trends in e-mobility are moving towards ever-larger and heavier electronic assemblies, a development which has thus far made inspection using inline inspection systems difficult. To achieve a defect tolerance of zero, randomly performing manual inspections is not sufficient as an alternative. Now, to meet the need for a solution for these inspection objects, such as power electronics, Viscom has developed a handling system capable of inspecting assemblies weighing up to 15 kg. With additional project-specific modifications, the new system can also inline inspect significantly heavier objects weighing up to 40 kg.

For electric drives and engine control units in the automotive industry, in telecommunications, in medical technology and in industrial technology, the need for inspection solutions for heavy electronic assemblies is on the rise. These assemblies are often very complex and populated with large components and sockets or completely assembled even before solder joint inspection is performed. To meet the need for flexible handling of large and heavy objects which need to be inspected fully automatically in the process line, Viscom has developed the new Heavy Flex handling solution. The Heavy Flex handling options are available for Viscom’s S3016 ultra system for optical inline 3D inspection from below, for the S3088 series 3D AOI systems, as well as for the iX7059 3D X-ray systems.

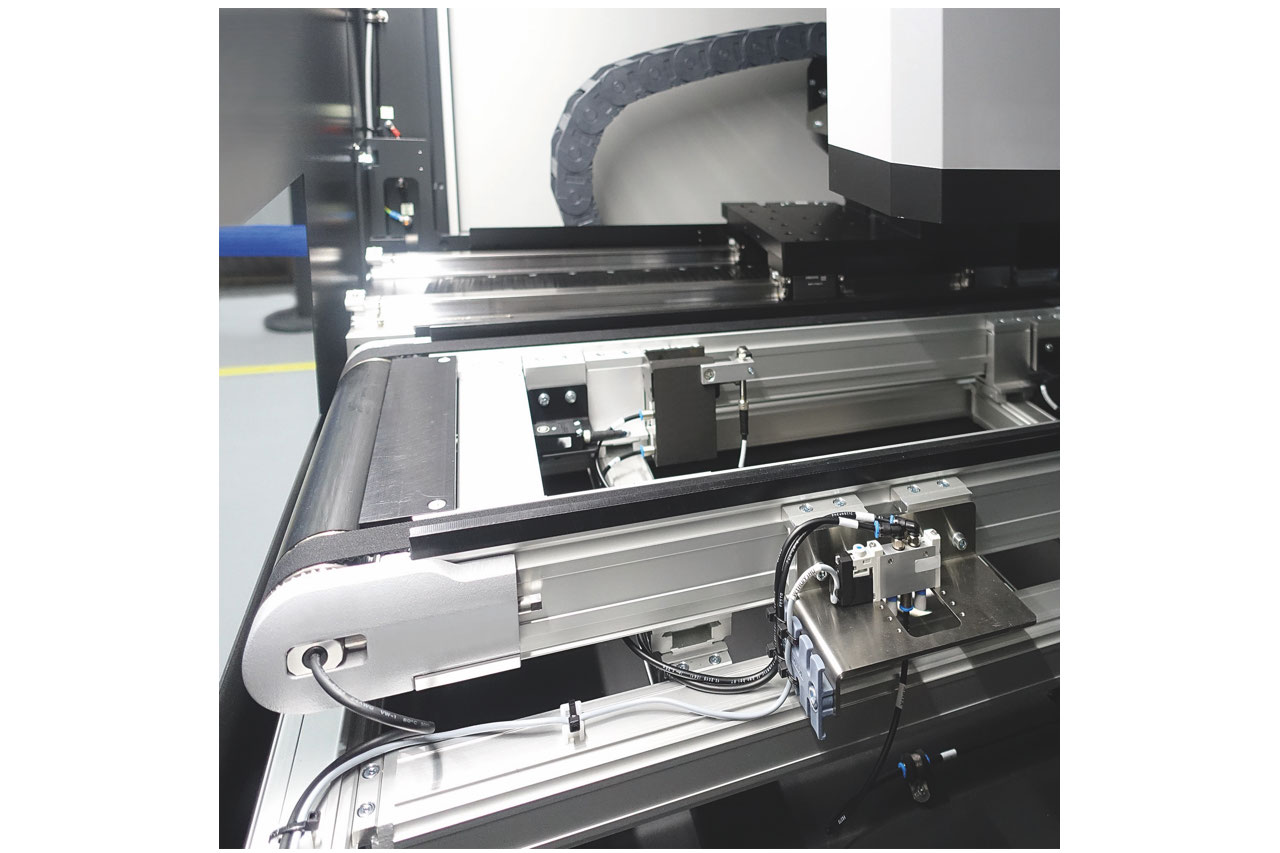

The Heavy Flex handling options make it possible to inline inspect PCBs weighing up to 15 kg and measuring up to 450 x 400 mm, by means of both automatic optical inspection (3D AOI) and automatic X-ray inspection (3D AXI). The inspection system can also be optionally outfitted to automatically inspect assemblies on workpiece carriers or inspection objects weighing up to 40 kg – all without altering the inspection system’s control components or dimensions. Thanks to the new handling concept, even very heavy inspection objects can be transported at a speed of up to 600 mm/s.

As a systems developer, Viscom also offers customer-specific solutions. The modular system design makes it possible to develop a complete specific solution if the customer’s existing process line transport system needs to be integrated into the optical or X-ray inline inspection. To ensure a seamless connection, Heavy Flex supports integration of commercially available transport systems for the fully automatic transport of assemblies on workpiece carriers. The connection is made by means of well-known standard interfaces. Thanks to the modular design principle, up to 70 percent of the work necessary to meet the customer’s specific needs in a custom transport integration project can be covered already at the start of the project. Additional assembly-specific adjustments and process integration at the customer’s facility normally require only a few man-days.