The trends in wire bonding include ever thinner wires, reduced pitches, but also more thick wire applications for more performance. An absolutely reliable inspection that also records 3D features, such as height information, is therefore essential to ensure first class quality. Using practical examples Wolf Rüdiger Pennuttis and Melanie Wons from Customer Care Team Bond will show in the webinar on the 4th of February 2021, from 10.00 to 10.30 (CET) how 3D Wire Bond Inspection works and how 3D technology simplify defect verification and lower the pseudo defect rate. The webinar is aimed at engineers as well as production and quality managers in electronics production. The registration for the upcoming free webinar is possible at Viscom’s website.

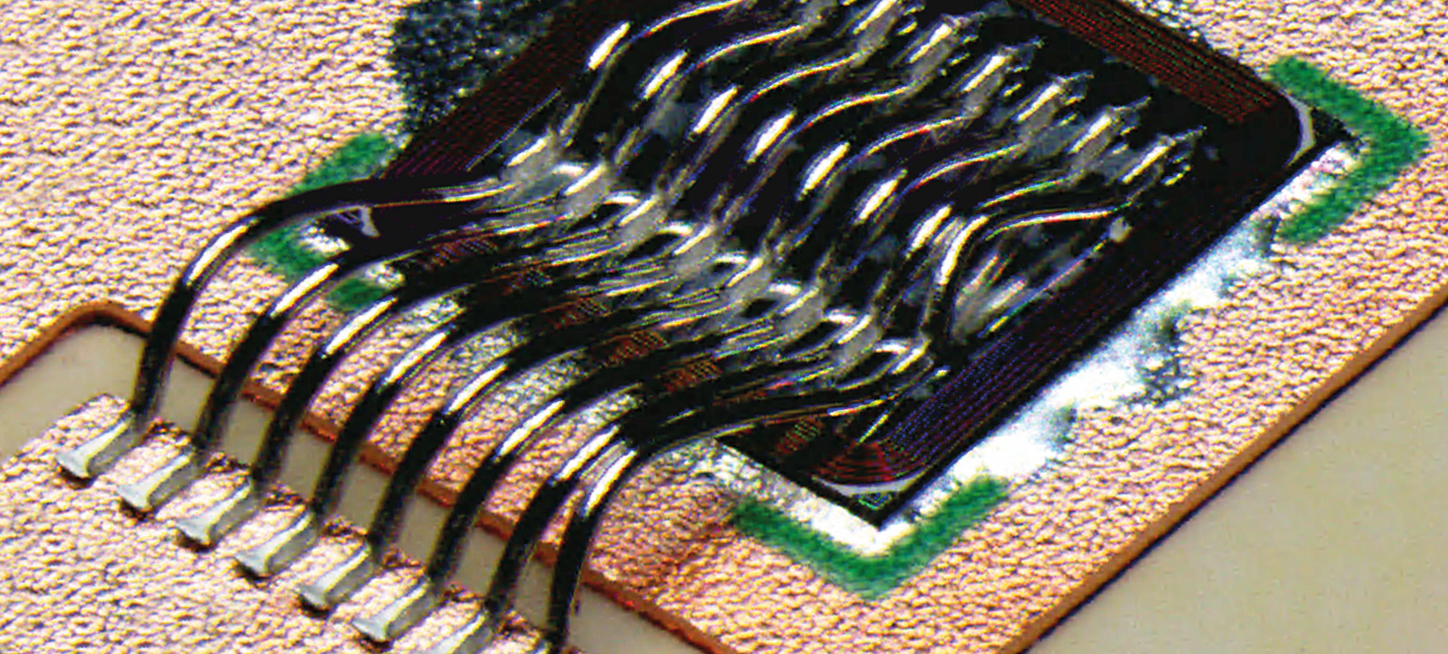

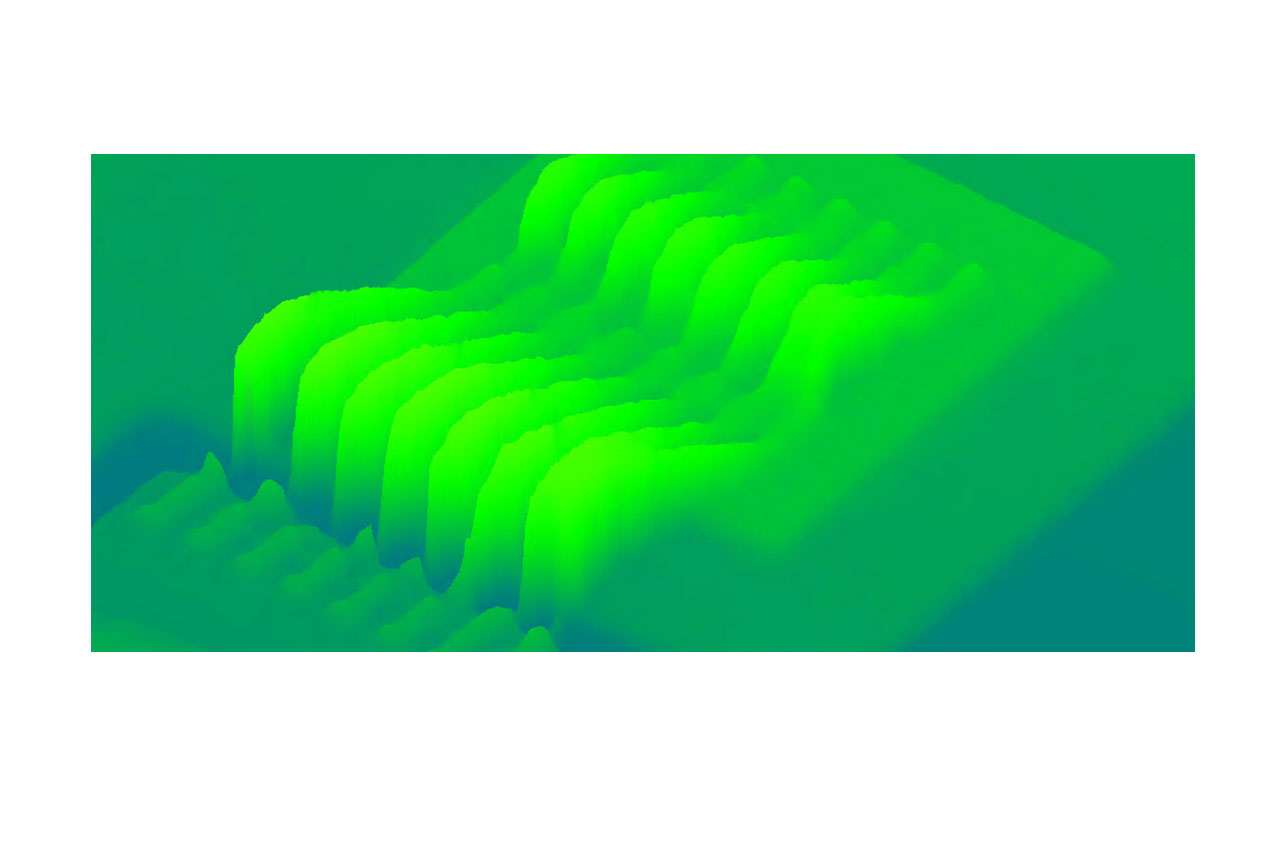

“With the newly developed 3D bond inspection from Viscom, a technology change is imminent: thanks to the additional height information, bond wires with a diameter of less than 50 µm can be measured in three dimensions,” Rüdiger says. “Especially if the installation heights are tightly limited by lids or gelling compounds, the actual height of the loops is an important test property in addition to the shape.” But also the standard algorithms of wire bond inspection allow an excellent safeguarding of wire bonded circuits against defects. Often, not only the lateral offset or the bending in x- and in y-direction plays a role. The loop shape of the highly specular wires is also effectively inspected.

During the webinar there will be a live demonstration of the best inspection strategies for all typical defects on electronic components, balls and wedges as well as wire defects. At the end of the session Rüdiger and Melanie will be available to answer individual questions.

About Viscom

Founded in 1984, Viscom AG is one of the leading suppliers worldwide in the field of assembly inspection within electronics production. With its headquarters and production site in Hanover, Germany, the company develops, produces and sells high-quality inspection systems from the areas of AOI, SPI, AXI, MXI, bond inspection as well as CCI for protective coating inspection. The systems from Hanover set high standards in terms of accuracy and speed. The product range covers the complete spectrum of optical inspection and X-ray inspection for small- and medium-sized companies as well as for large series production. Viscom systems are used for 100% automatic inspection of electronic assemblies such as in the production of automotive electronics, aerospace technology or in the manufacture of telecommunications electronics.