The developments of the latest Cheetah EVO system release focused on three topics of paramount importance to inspectors in the electronics industry: accurate and stable inspection results, the protection of sensitive test parts, and increased efficiency of the inspection process. The solution includes a new water-cooled X-ray tube, dose monitoring, plus automated analysis workflows. The other good news is that these optimizations are also available as upgrades for existing owners of Cheetah EVO test systems.

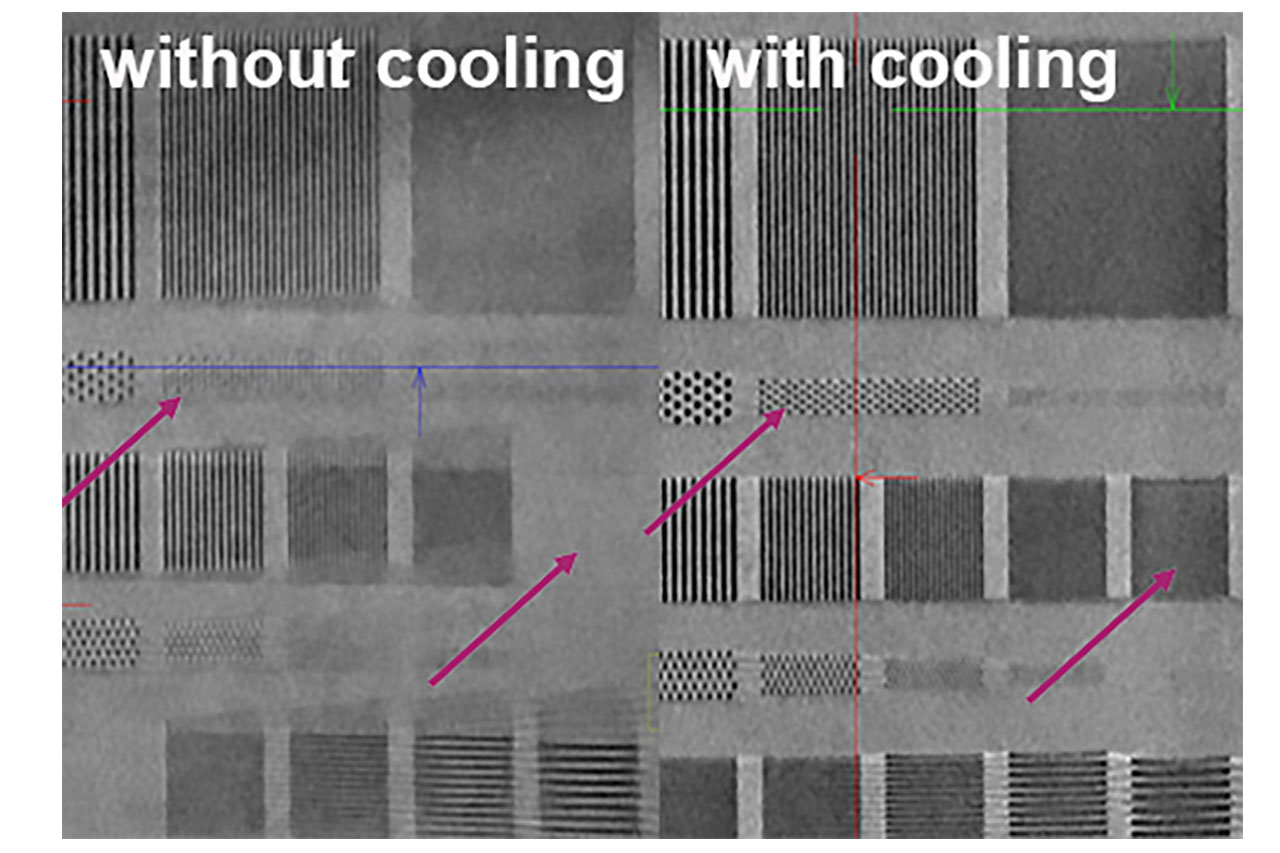

Particularly when it comes to detailed analyses using computed tomography, one often observes blurring in the reconstructed image and the CT data, which can lead to negative impairments of the test result. The reason is the heat generated by prolonged irradiation which causes the material to warp on the one hand and the focal spot to drift on the other. The newly introduced 160kV microfocus X-ray tube is equipped with a water-cooling system that dissipates the heat generated, ensuring a stable focal spot, and preventing unwanted influence on the material. The enormous increase in detail resolution is clearly visible in the 2D radioscopy image.

Electronic components with their silicon layers are very sensitive to X-rays and can get damaged or destroyed by a radiation dose that is too high. The Comet Yxlon microfocus systems use extra sensitive detectors which deliver excellent results, even at the lowest radiation levels. Now there is the additional option of dose monitoring. The tool continuously measures the radiation dose and compares it with the entered limit ranges. A traffic light system shows when the radiation has reached critical values, and the operator is notified by an alarm and eventual system stop, when the limit is about to be exceeded. The damaged part(s) are easily identified with a detailed log. Optionally available is a Dose Reduction Kit, which reduces the most harmful photons by using a collimator and various filters, further protecting sensitive test parts.

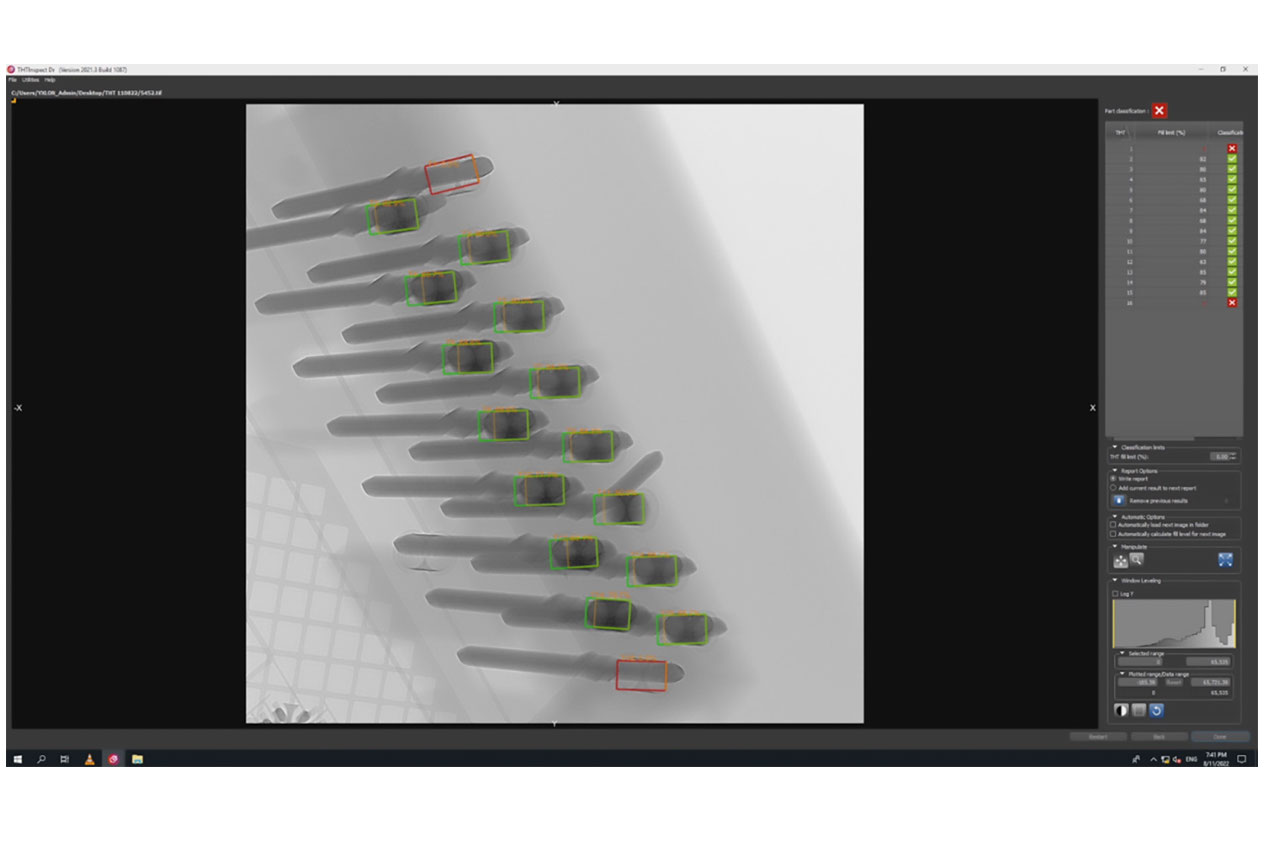

Cheetah EVO provides objective and repeatable inspection results with the help of automated processes. These include VoidInspect CL (void analysis based on computed laminography), VoidInspect DR (void analysis based on two-dimensional radioscopy) and THTInspect DR for the fill-level analysis of through-hole connections, based on 2D radioscopy. The interaction of the intuitive FGUI user interface and ORS’ top-of-the-line software provide easy and quick performance of these reliable analyses, resulting in significantly increased productivity.

Comet Yxlon is exhibiting the new Cheetah EVO release in booth 2933 at IPC APEX 2023. To find out more about this new release or to schedule a scan at the show, please contact matthew.kerschinske@comet.tech.