Juki Automation Systems (JAS), Inc., a world-leading provider of automated assembly products and systems and subsidiary of Juki Corporation, today announced plans to exhibit at SMTA International, scheduled to take place Nov 2-3, 2022 at the Minneapolis Convention Center in Minnesota. Juki’s team will be available to demonstrate the award-winning ISM UltraFlex 3600S, Incoming Material Station and RS-1R in Booth #731.

The ISM UltraFlex 3600S changes the game in automated component storage. The unit is a new benchmark in the electronic component storage market, pushing performances beyond current possibilities, allowing the user to reconfigure the unit as their needs change. The 3600S is faster and more efficient than the previous model at extracting and returning reels. It has a new robotic arm and can store up to 3600 reels in individual cases.

With the Incoming Material Station, operators can speed up registration of new reels, avoid mistakes and increase the traceability of each individual Unique ID. The Autoincoming software automatically reads and imports information from the supplier and/or customers’ label and generates a Unique ID label that can be shared with pick and place machines and/or ERP software. The operator simply positions the material on the Station and the high-resolution camera will read all the needed codes and information, save a picture for traceability purposes, print the new label, and optionally send the UID and material PO to a customers’ receiving system, ERP and/or MES software.

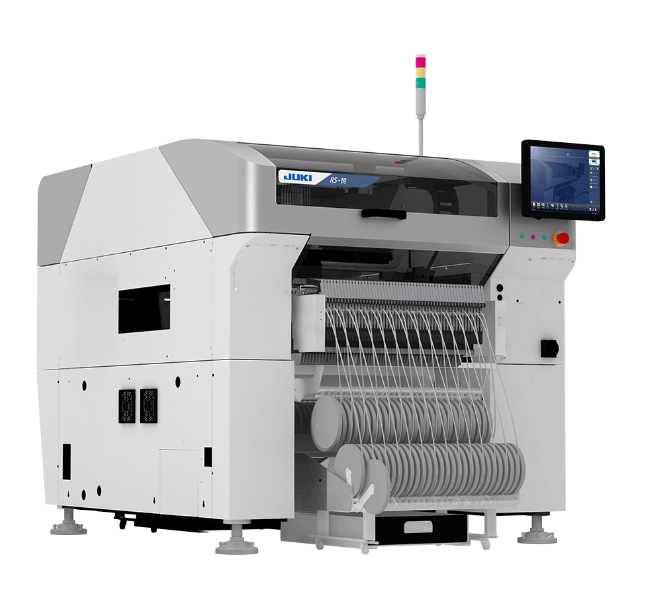

The RS-1R features the TAKUMI 8 nozzle placement head that automatically adjusts pick-and- placement height on-the-fly to optimize speed while offering a high degree of flexibility. Available RFID nozzles track the performance and maintenance of each individual nozzle by serial number. With the new PG-01 offline teach camera and line optimization JaNets/NPI Plus software, the RS-1R provides easy data entry for faster programming.

For more information about Juki, visit www.jukiamericas.com.